A kind of preparation method of fast-flow temperature-sensitive super-porous biological separation medium

A bio-separation, super-porous technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor chemical stability, low processing capacity, low mechanical strength, etc., and achieve simple preparation methods, good biocompatibility, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

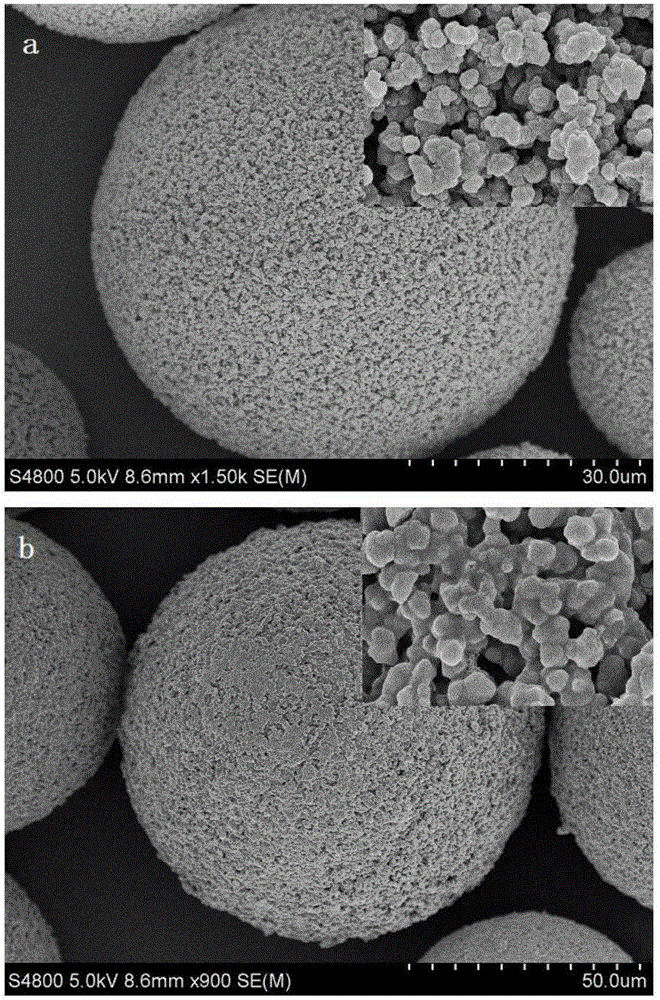

[0038] Take 2g of super-porous polystyrene microspheres (PS) and add 50mlCS 2 Soak, followed by adding anhydrous AlCl 3 3.7g and 3.02g of chloroacetyl chloride were stirred and reacted at 40°C for 3h, and the product was washed with absolute ethanol, 3% HCl and deionized water successively, and dried in vacuum at 25°C for 3h to prepare PS-Cl.

[0039] Weigh 0.25g of PS-Cl and place it in a pear-shaped Schlenk bottle 1, fill it with argon gas for deoxygenation three times, and set aside; then put the catalyst CuCl (20.54mg) ligand PMDETA (143.54mg) and functional monomer MEO2MA (2.164g) Mix well with OEGMA (0.475g) and solvent methanol / water (4:1, 15ml) in the pear-shaped Schlenk bottle 2, freeze with liquid nitrogen and evacuate the oxygen three times; Introduce into the pear-shaped Schlenk bottle 1; finally, transfer the pear-shaped Schlenk bottle 1 to a water bath shaker for 18 hours of water bath shaking reaction (rotation speed: 140r / min), and the water temperature is 30°...

Embodiment 2

[0041] Take 2g of ultra-large-porous polystyrene microspheres (PS) and soak them in 30ml of dichloromethane, then add anhydrous AlCl 3 4.2g and 3.89g of 2-chloroisobutyryl chloride were reacted with stirring at 50°C for 5h. The product was washed with absolute ethanol, 3% HCl and deionized water successively, and dried in vacuum at 40°C for 2h to prepare PS-Cl.

[0042] Weigh 0.25g PS-Cl and place it in a pear-shaped Schlenk1 bottle, fill it with argon to deoxygenate three times, and set aside; then put the catalyst CuCl (20.46mg), the ligand Me 6 TREN (190.5mg)﹑functional monomer MEO 2 MA (3.576g) and OEGMA (0.475g) ﹑ solvent isopropanol / water (4:1, 17ml) were placed in a pear-shaped Schlenk bottle 2 and mixed evenly, and liquid nitrogen was frozen and evacuated for three times to remove oxygen; The liquid in the pear-shaped Schlenk bottle 2 was introduced into the pear-shaped Schlenk bottle 1; finally, the pear-shaped Schlenk bottle 1 was transferred to a water bath shaker ...

Embodiment 3

[0044] Take 2.5g of ultra-large-porous polystyrene microspheres (PS) and soak them in 35ml of dichloroethane, then add anhydrous AlCl 3 4.4g and 4.52g of bromoacetyl bromide were stirred and reacted at 50°C for 5h. The product was washed with absolute ethanol, 3% HCl, and deionized water in turn, and dried in vacuum at 35°C for 3h to prepare PS-Br.

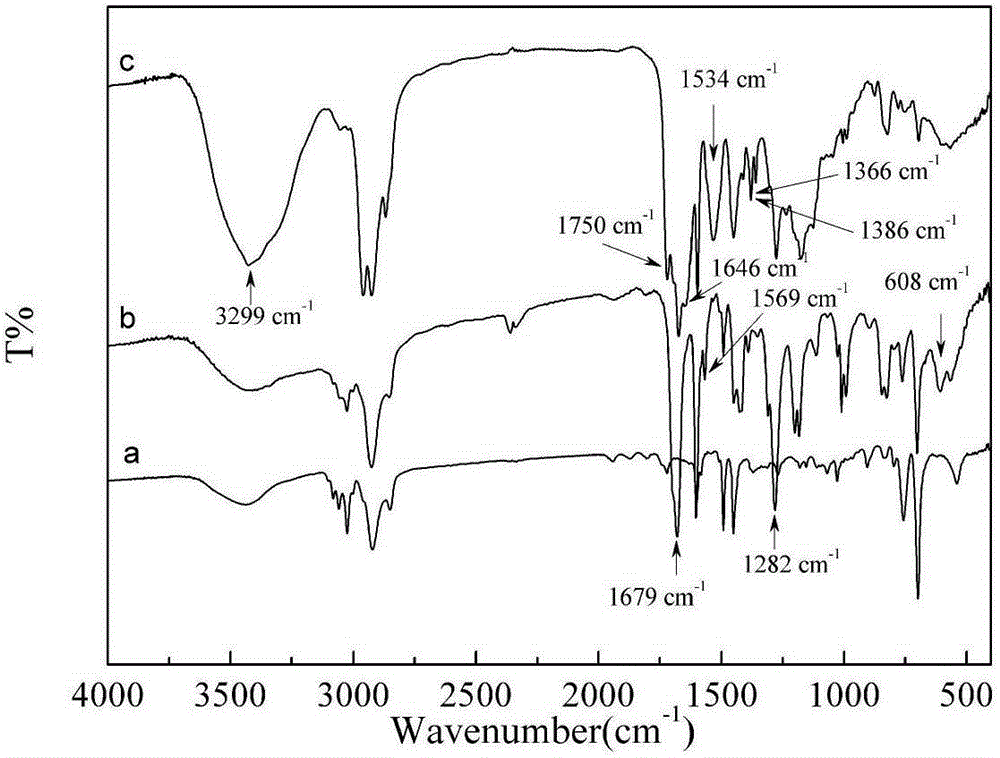

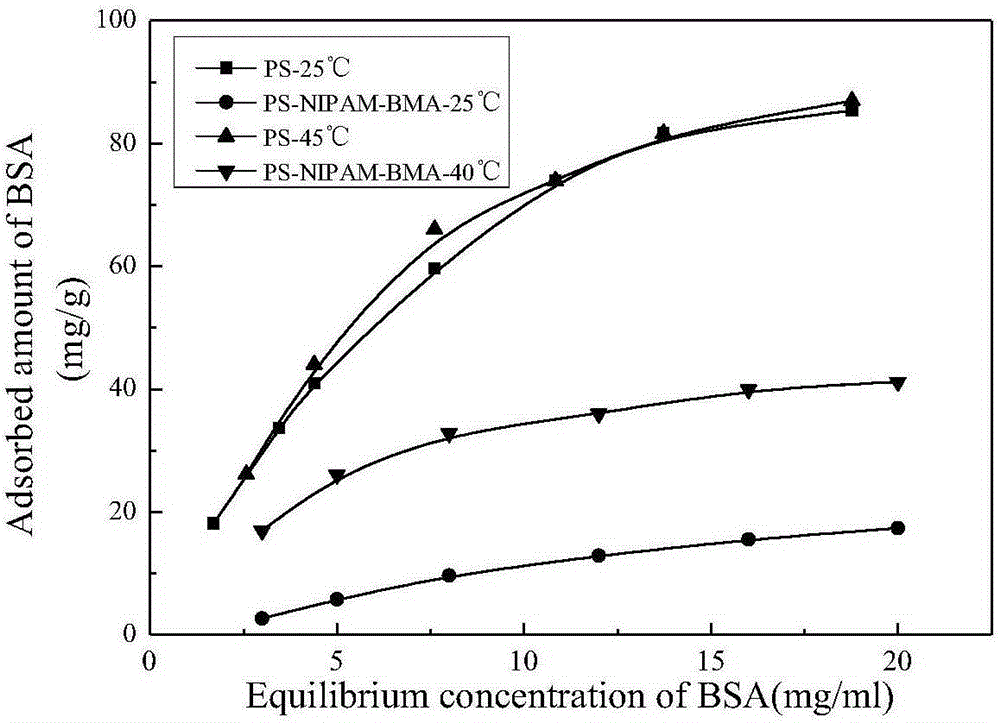

[0045] Weigh 0.26gPS-Br and place it in the pear-shaped Schlenk bottle 1, fill it with argon to remove oxygen three times, and set it aside for use; then put the catalyst CuCl (18.3mg) / CuCl 2 (3.0mg), ligand Bipy (130.73mg), functional monomer N-isopropylacrylamide (NIPAM) / butyl methacrylate (BMA) (90:10, 2.46g), solvent methanol / water (3 : 1, 22ml) in the pear-shaped Schlenk bottle 2 and mixed evenly, liquid nitrogen freezing and vacuum deoxygenation three times; then use double needles to introduce the liquid in the pear-shaped Schlenk bottle 2 into the pear-shaped Schlenk bottle 1; Bottle 1 was transferred to a water bath shak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com