A fully degradable waterproof food packaging material and its preparation method

A packaging material, a complete degradation technology, applied in the field of organic polymer material preparation, can solve the problems of poor biodegradability, difficult to recycle, etc., to achieve the effect of improving the degree of compactness, compact structure, and improving waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the fully degradable waterproof food packaging material of the present embodiment is as follows:

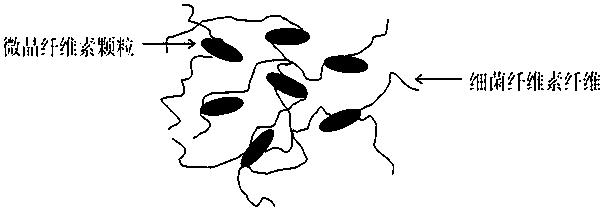

[0025] (1) Disperse 5.0g bacterial cellulose fibers (polymerization degree 1500~2000, molecular weight 250000~300000) in 500g absolute ethanol, and prepare 504g uniformly dispersed bacterial cellulose through 80MPa high-pressure homogenization treatment twice Fiber dispersion system;

[0026] (2) Add 1.0g microcrystalline cellulose (microcrystalline cellulose particle size is 20μm~50μm, polymerization degree is 200~220) into 100g distilled water, add 0.2g acetic anhydride and 2.5 g concentrated sulfuric acid for surface modification, after 6 hours of treatment, the microcrystalline cellulose was washed with distilled water to neutrality, and after vacuum filtration, the filter cake was dried at 40°C for 48 hours to obtain 1.1 g of modified microcrystalline cellulose particles. The mechanical stirring speed in the modification process is 120r / min;...

Embodiment 2

[0031] The preparation method of the fully degradable waterproof food packaging material of the present embodiment is as follows:

[0032] (1) Disperse 7.0g bacterial cellulose fibers (polymerization degree 1500~2000, molecular weight 250000~300000) in 700g absolute ethanol, and prepare 705g uniformly dispersed bacterial cellulose through 80MPa high-pressure homogenization treatment twice Fiber dispersion system;

[0033](2) Take 3.0g microcrystalline cellulose (microcrystalline cellulose particle size is 20μm~50μm, polymerization degree is 200~220) and add it to 200g distilled water, add 0.6g acetic anhydride and 7.5 g of concentrated sulfuric acid for surface modification, after 6 hours of treatment, the microcrystalline cellulose was washed to neutrality with distilled water, and after vacuum filtration, the filter cake was dried at 45°C for 48 hours to obtain 3.2 g of modified microcrystalline cellulose particles. The mechanical stirring speed in the modification process ...

Embodiment 3

[0038] The preparation method of a kind of fully degradable waterproof food packaging material of the present embodiment is as follows:

[0039] (1) Take 6.0g bacterial cellulose fiber (polymerization degree is 1500~2000, molecular weight is 250000~300000) and disperse it in 600g absolute ethanol, after 80MPa high pressure homogeneous treatment twice to prepare 603g uniformly dispersed bacterial cellulose Fiber dispersion system;

[0040] (2) Add 10.0g microcrystalline cellulose (microcrystalline cellulose particle size is 20μm~50μm, polymerization degree is 200~220) into 500g distilled water, add 2g acetic anhydride and 25g concentrated Sulfuric acid was used for surface modification. After 6 hours of treatment, the microcrystalline cellulose was washed with distilled water to neutrality. After vacuum filtration, the filter cake was dried at 42°C for 48 hours to obtain 10.3 g of modified microcrystalline cellulose particles. The mechanical stirring speed in the process is 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com