Photosensitive composite thin film material and preparation method and application thereof

A composite film and photosensitive technology, which is applied in the fields of optical recording/reproduction, optical recording carrier manufacturing, optical recording carrier, etc., and can solve problems such as low contrast, low storage density, and slow storage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Such as figure 1 Shown, the preparation method of the photosensitive composite film material of the embodiment of the present invention comprises the following steps:

[0048] S101: Synthesizing multi-metal oxide nanostructures by hydrothermal method;

[0049] S102: Soak the thoroughly cleaned substrate in a polymer solution for a period of time, so that a layer of polymer film is adsorbed on the surface of the substrate;

[0050] S103: immersing the substrate adsorbed with the polymer film in a solution containing multi-metal oxide nanostructures for a period of time to make it adsorb a layer of multi-metal oxide film;

[0051] S104: Repeating S102 and S103 multiple times to prepare the required film composite material.

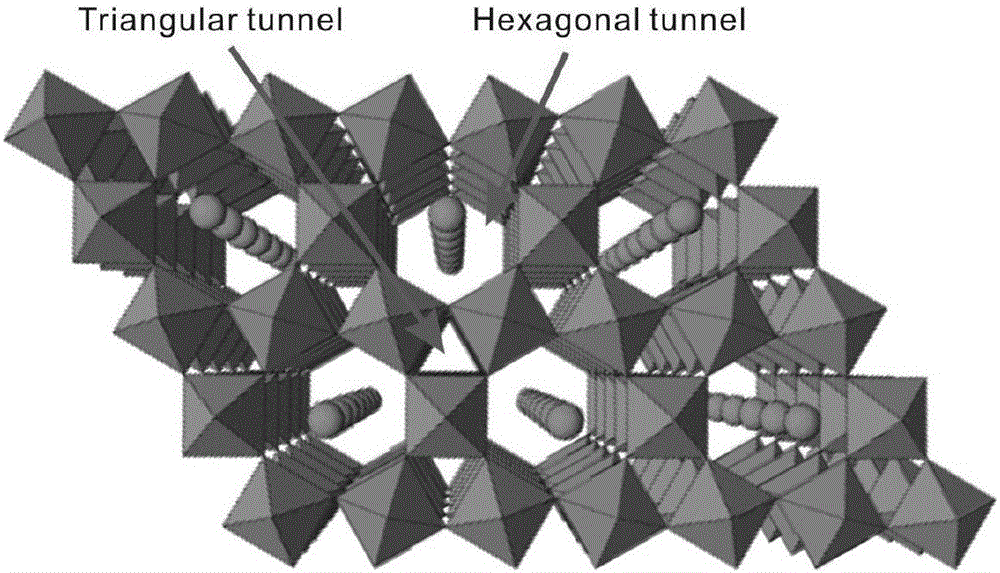

[0052] Wherein, in the step S101, the multi-metal oxides are tungsten bronze, molybdenum-doped tungsten bronze, hexagonal tungsten trioxide; the nanostructures are nanorods, nanoparticles, nanosheets and the like.

[0053] The polymer used in step ...

Embodiment 1

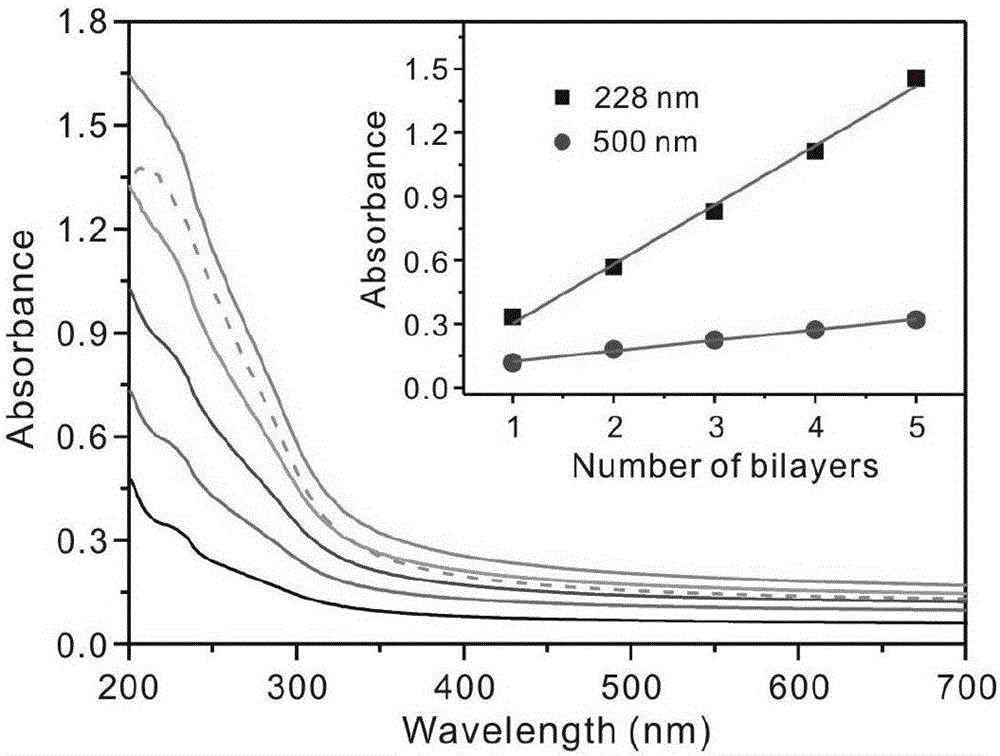

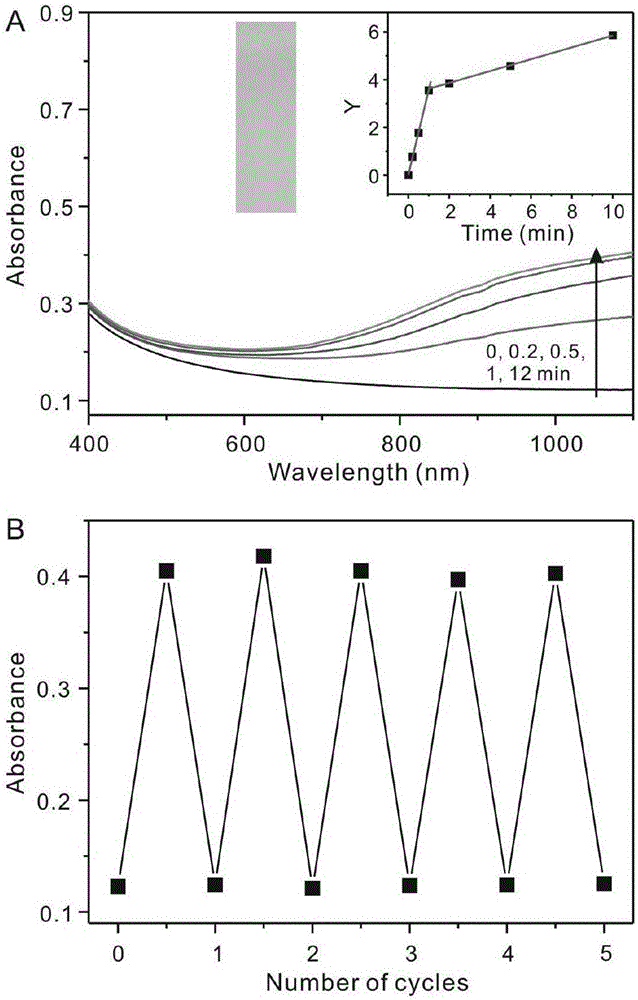

[0059] Embodiment 1, the preparation of HTB / PEI self-assembled composite color-changing film

[0060] At 80°C, first use Piranha solution (H 2 o 2 :H 2 SO 4 =3:7v / v) The quartz substrate was treated for 30 minutes, and then cleaned with deionized water. Then immerse the substrate in NH 4 OH:H 2 o 2 :H 2 O (1:1:5v / v) solution, treated at 70°C for 30 minutes, then fully washed with deionized water, and blown dry with nitrogen. Wash the cleaned quartz substrate at 10 -2 M Soak in PEI solution (pH=9.0) for 20 minutes to modify PEI on the surface of the substrate. Then the substrate adsorbed with PEI film was immersed in hexagonal tungsten bronze (HTB) nanorods (10 -3 M, pH=3.0) solution, soak for 20 minutes to make it adsorb a layer of HTB nanorods; wash the substrate with ultrapure water, and dry it with nitrogen. The substrate was then immersed in a protonated PEI solution (10 -2 M, pH=3.0) for 20 minutes. Repeat the above steps several times, each time for 20 minut...

Embodiment 2

[0061] Example 2, Mo 0.05 -Preparation of HTB / PEI self-assembled composite color-changing film

[0062] At 80°C, first use Piranha solution (H 2 o 2 :H 2 SO 4 =3:7v / v) The quartz substrate was treated for 30 minutes, and then cleaned with deionized water. Then immerse the substrate in NH 4 OH:H 2 o 2 :H 2 O (1:1:5v / v) solution, treated at 70°C for 30 minutes, then fully washed with deionized water, and blown dry with nitrogen. Wash the cleaned quartz substrate at 10 -2 M Soak in PEI solution (pH=9.0) for 25 minutes to modify PEI on the surface of the substrate. Then the substrate adsorbed with PEI film was immersed in Mo-doped hexagonal tungsten bronze (Mo 0.05 -HTB) nanorods (10 -3 M, pH=3.0) solution, soak for 25 minutes to make it absorb a layer of Mo 0.05 -HTB nanorods; the substrate was washed with ultrapure water and dried with nitrogen gas. The substrate was then immersed in a protonated PEI solution (10 -2 M, pH=3.0) for 25 minutes. Repeat above steps s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com