Curing adhesive used for preparation of microsection sample of printed circuit and preparation method thereof

A technology for metallographic slicing and printed circuits, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of complicated manufacturing process, high cost, poor transparency of cured products, etc., and achieve high bonding strength , low cost, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A component

[0029] Weigh 10 g of polymethyl methacrylate, add 0.1 g of benzoyl peroxide and 0.05 g of sodium lauryl sulfate to it, grind and mix evenly with a mortar;

[0030] B component

[0031] 4g of methyl methacrylate with a purity of 99.0% and 2g of acetone with a purity of 99.5% were weighed, and 0.01g of N,N-dimethyl-p-toluidine was added dropwise thereto, and stirred and mixed evenly.

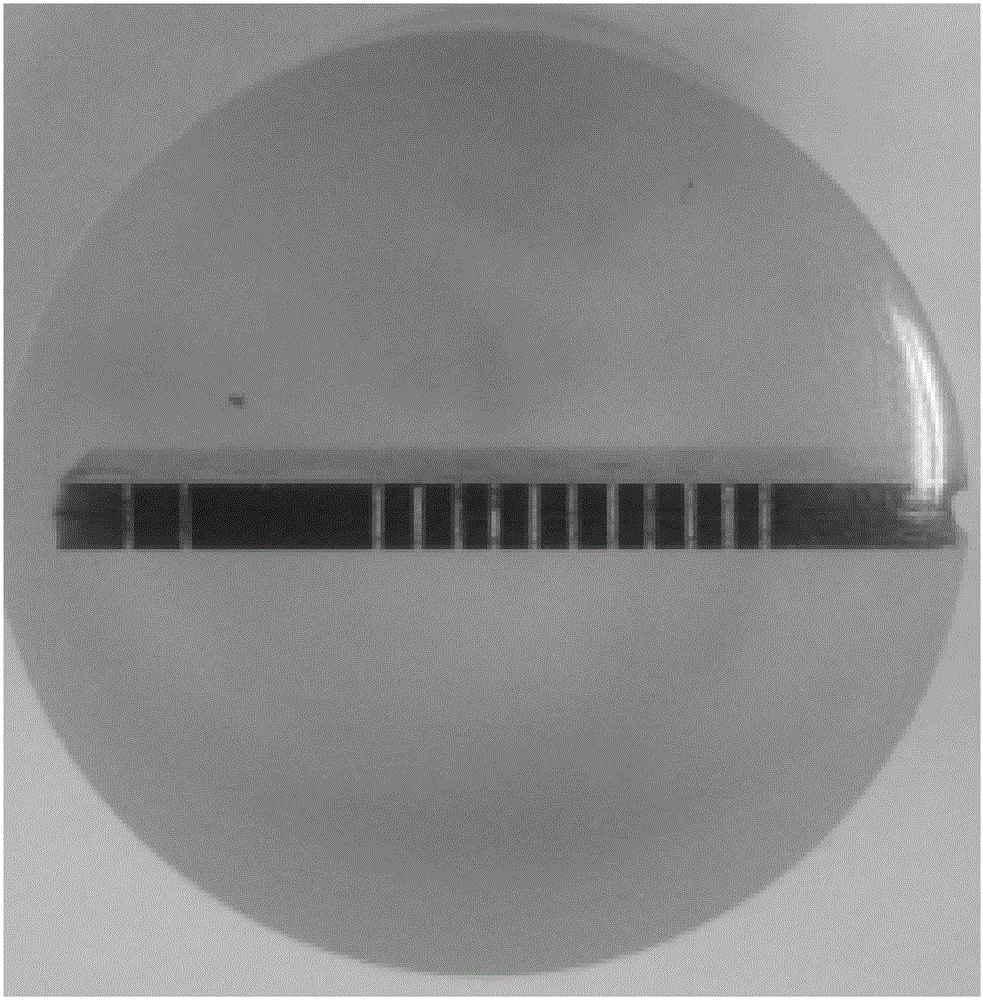

[0032] Put the above-prepared components A and B in a mosaic mold with an inner diameter of 25 mm and a height of 22 mm at a mass ratio of 2:1, and cure at room temperature for 30 minutes. like figure 1 As shown, it is a transparent effect diagram of the mosaic slice after the cured glue is mixed and cured in this embodiment.

Embodiment 2

[0034] A component

[0035] Weigh 20 g of polymethyl methacrylate; add 0.15 g of benzoyl peroxide and 0.05 g of sodium dodecylbenzene sulfonate to it, and mix well.

[0036] B component

[0037] 8 g of methyl methacrylate with a purity of 99.0% and 4 g of ethyl acetate with a purity of 99.5% were weighed, and 0.03 g of N,N-dimethylaniline was added thereto, and stirred and mixed uniformly.

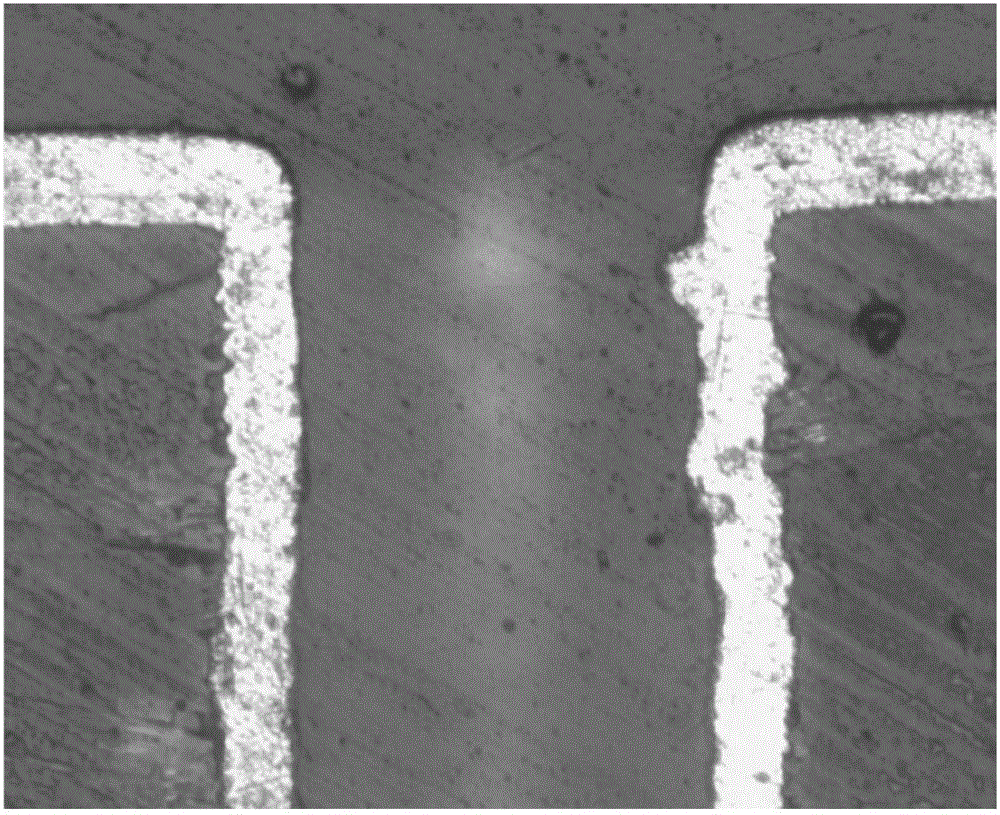

[0038] Put the above-prepared components A and B in a mosaic mold with an inner diameter of 25 mm and a height of 22 mm at a mass ratio of 2:1, and cure at room temperature for 30 minutes. like figure 2 As shown, it is the effect diagram of the cured glue of this embodiment used for metallographic section observation of the metallographic structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com