Microbial mixed flora for fermenting to produce 1,3-propanediol and fermentation method

A technology of mixed flora and fermentation method, applied in the field of bioengineering, can solve the problems of unverified biological safety, inhibition of bacterial growth and metabolism, unknown composition of bacterial species, etc., and achieves strong tolerance, easy operation, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Screening of microbial flora domesticated to produce 1,3-propanediol from anaerobic activated sludge

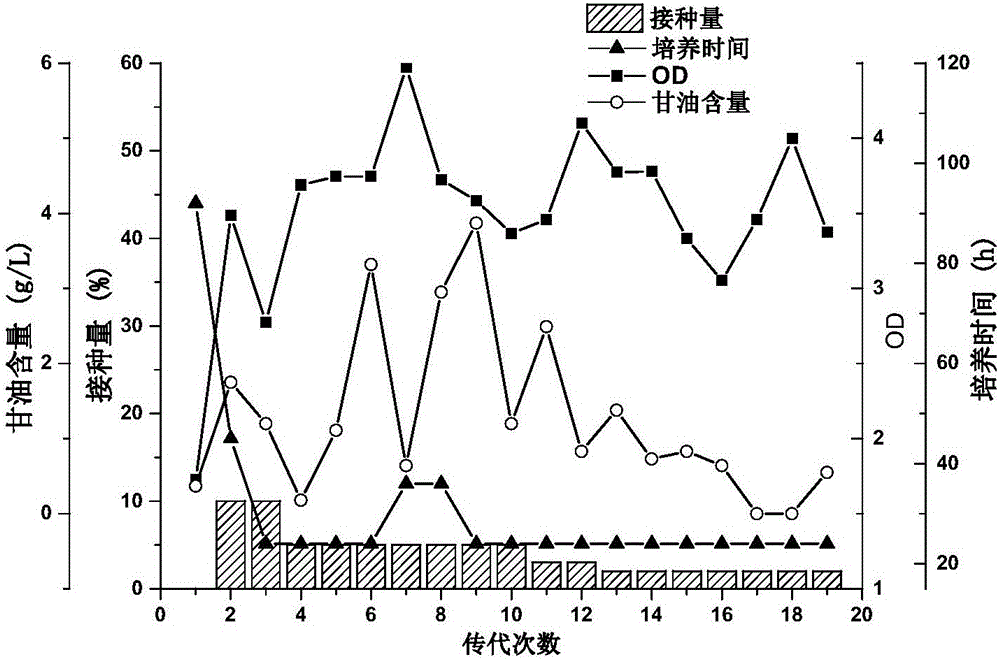

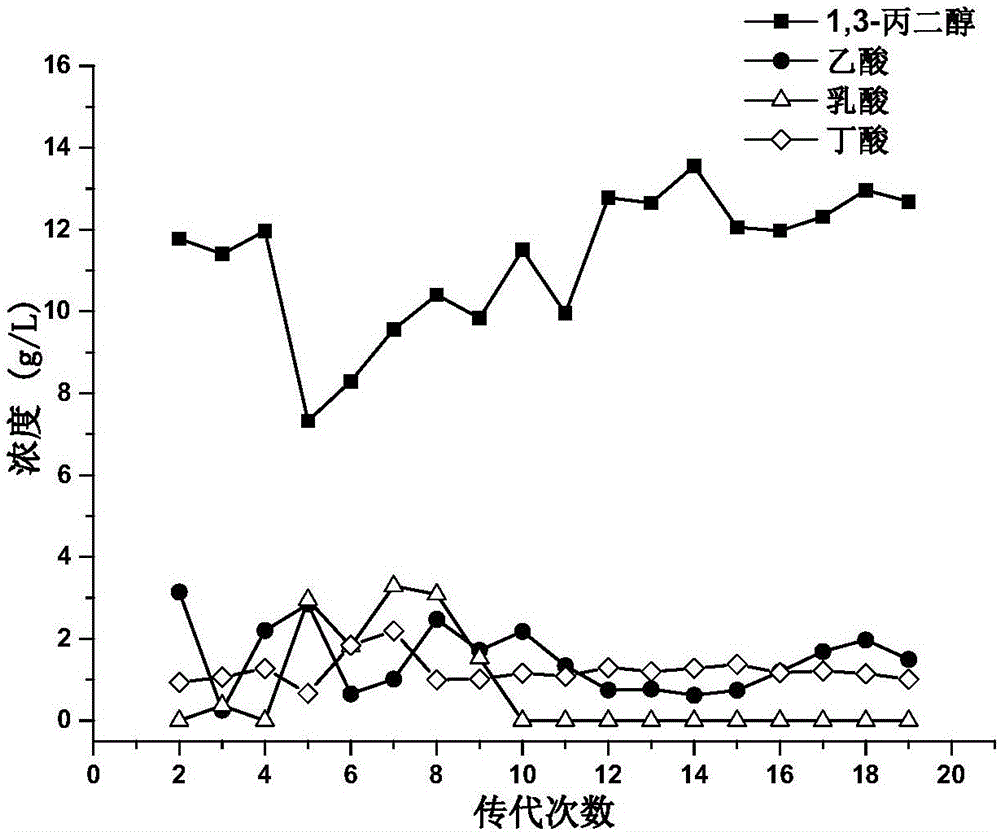

[0043] Take 2.0g of anaerobic activated sludge, insert it into the seed medium containing 22g / L crude glycerol, and culture it anaerobically under the conditions of 37°C and 200r / min, and gradually reduce the inoculation amount for subculture after the glycerol in the medium is exhausted. After 20 subcultures, the biomass and metabolism of the flora were basically stable. Natural enrichment and domestication processes such as figure 1 and 2 As shown, the overall can be divided into three stages: initial stage (2nd generation to 4th generation), fluctuation period (5th generation to 12th generation) and stable period (after 12th generation). The initial stage of screening is the stage when the flora structure adapts to the culture environment. It can enrich the strains that can use glycerol and grow rapidly, and eliminate the strains that cannot use substrat...

Embodiment 2

[0047] Example 2 Tolerance of anaerobic microbial flora C2-2M to crude glycerol

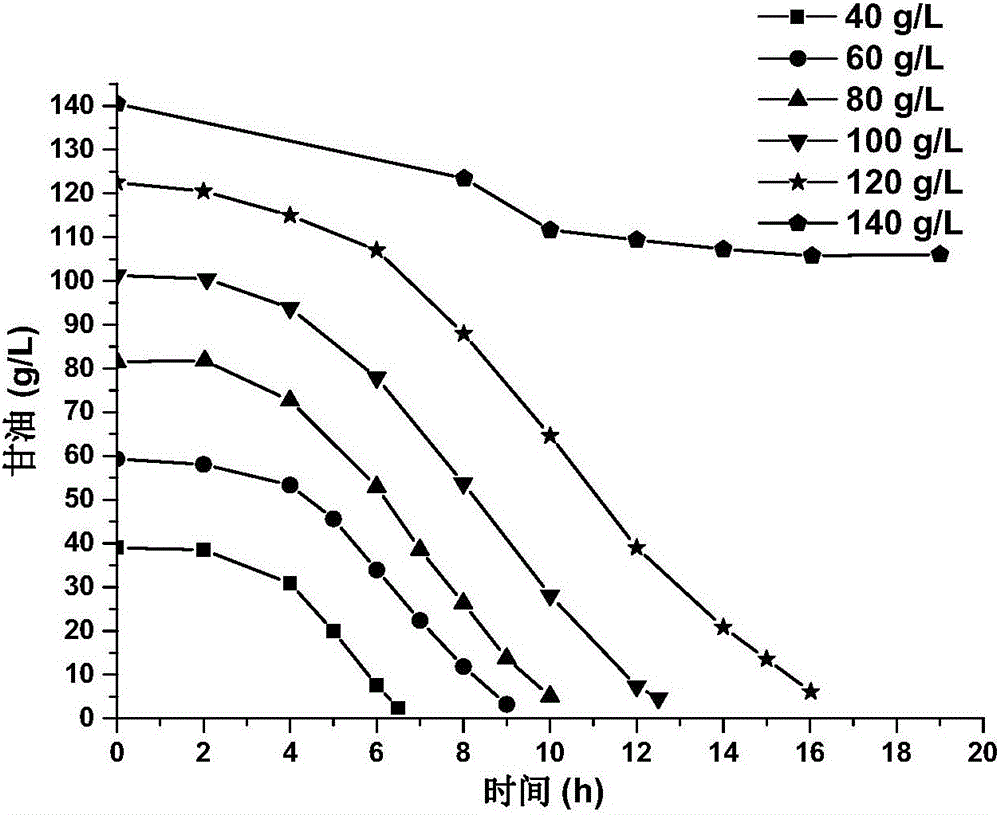

[0048] After the mixed flora C2-2M obtained in Example 1 is cultivated in the seed medium, it is inoculated into a 5L fermenter with 2L fermentation medium by 10% volume ratio to cultivate, and the initial glycerol concentration of each batch of fermentation is changed from 40g / L is gradually increased to 140g / L (adding an appropriate amount of crude glycerin to prepare a fermentation medium with an initial glycerin concentration of 40-140g / L), as image 3 shown. The fermentation results show that the microbial flora C2-2M has a strong tolerance to crude glycerol, and can grow and metabolize in crude glycerol with a glycerol content of 120g / L. The concentration of 1,3-propanediol reaches 60.61g / L, and the molar conversion The rate is 0.63mol / mol, and the production intensity is 3.79g / (L·h). Relatively speaking, the batch fermentation efficiency is higher when the initial glycerol concentration...

Embodiment 3

[0049] Example 3 Batch fermentation of anaerobic bacteria S1 with crude glycerol as substrate

[0050] The fermentation results of single bacterium S1 using 80g / L crude glycerol as substrate are as follows: Figure 5 As shown, the concentration of 1,3-propanediol is 44.34g / L, the molar conversion rate is 0.67mol / mol, and the production intensity is 0.92g / (L·h). Although the concentration of 1,3-propanediol and the molar conversion rate of crude glycerol fermented by single bacteria S1 are similar to the fermentation level of microbial flora C2-2M, the fermentation time is 38 hours longer than that of microbial flora fermentation, and the production intensity is only for microbial flora fermentation of 22.4%. This indicated that the microbial flora C2-2M had better fermentation performance than the single bacteria, could tolerate higher glycerol concentration, and the fermentation time was shorter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com