Preparation method of isobutyramide

A technology of isobutyramide and isobutyronitrile, which is applied in the field of isobutyramide preparation, can solve the problems of difficult environmental protection requirements, increasing the difficulty of isobutyramide, and increasing the probability of containing harmful substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

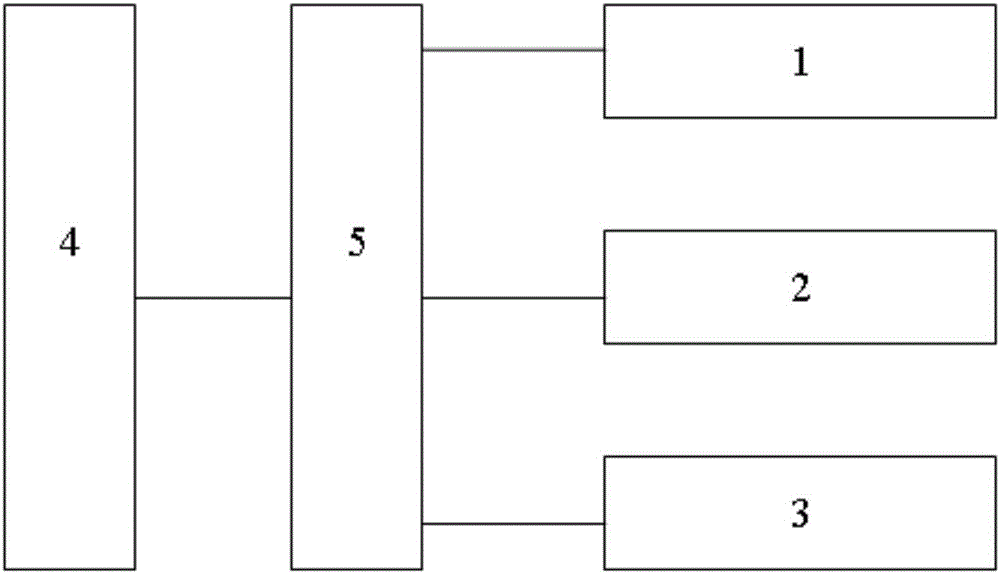

[0023] The implementation of the composite window control platform based on wind volume detection of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] A preparation method of isobutyramide, the method comprising:

[0025] Carry out the following steps in the reactor in the smart factory:

[0026] (1): The treatment of nitrile hydratase catalyst: the fermented liquid obtained by fermenting the nitrile hydratase production strain is separated with a 1.5mm sintered metal filter, and then cleaned twice with deionized water, and the strain is star-shaped Nocardia ATCC 19247;

[0027] (2): Preparation of isobutyramide by hydration of isobutyronitrile: adding the cleaned nitrile hydratase catalyst to deionized water, the mass ratio of the amount of nitrile hydratase catalyst added to the amount of deionized water added is 0.02:1, isobutyramide The mass ratio of the amount of nitrile added to the amount of deionized water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com