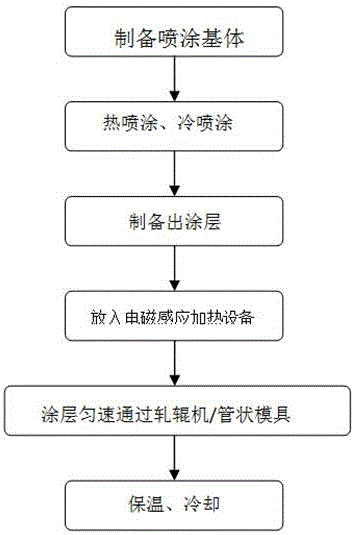

Method for eliminating porosity of sprayed coating

A technology of porosity and coating, which is applied in the field of spray coating sealing holes, can solve the problems of lack of pores inside the coating and affect the long-term application performance of the coating, so as to improve the comprehensive mechanical properties, high energy utilization rate and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Select pure aluminum wire with a diameter of 2.0 mm, and install the wire on the arc spraying equipment.

[0027] (2) The process parameters are as follows: argon is used as the spraying atmosphere, the atomization pressure is 0.8MPa; the spraying voltage is 32V; the spraying current is 180A; the spraying distance is 180mm; the deposition rate is 128g / min; the coating thickness is 200μm.

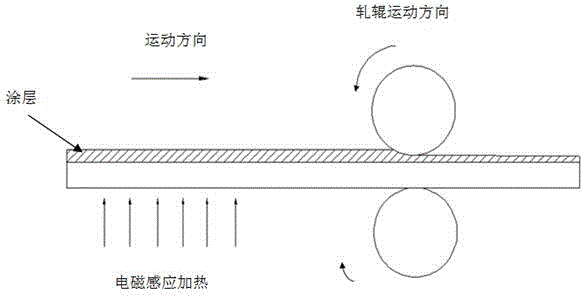

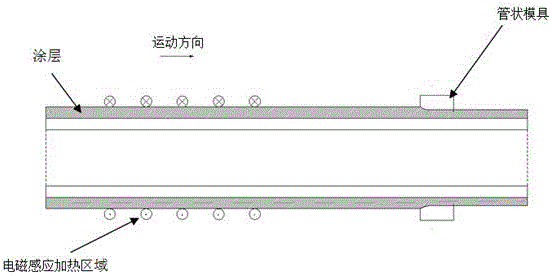

[0028] (3) Put the prepared coating into the electromagnetic induction heating equipment and heat the temperature to 500°C.

[0029] (4) Start the roll machine to make the coating pass through the roll at a constant speed, with a reduction of 15 μm.

[0030] (5) Cool with the furnace after holding the heat for 50 minutes; at this time, the porosity of the coating will drop to zero.

Embodiment 2

[0032] (1) Select pure zinc wire with a diameter of 2.2 mm, and install the wire on the arc spraying equipment.

[0033] (2) Argon is used as the spraying atmosphere, the atomization pressure is 0.7MPa; the spraying voltage is 32V; the spraying current is 180A; the spraying distance is 180mm; the deposition rate is 130g / min; the coating thickness is 300μm. The coating porosity is 14%.

[0034] (3) Put the prepared coating into the electromagnetic induction heating equipment and heat the temperature to 380°C.

[0035] (4) Start the roll machine to make the coating pass through the roll at a constant speed, with a reduction of 40 μm.

[0036] (5) After 60 minutes of heat preservation, cool with the furnace; at this time, the porosity of the coating will drop to zero.

Embodiment 3

[0038] (1) Select a nickel-aluminum alloy wire with a diameter of 2.5 mm and install it on the arc spraying equipment.

[0039] (2) Argon is used as the spraying atmosphere, the atomization pressure is 0.6MPa; the spraying voltage is 32V; the spraying current is 180A; the spraying distance is 150mm; the deposition rate is 135g / min; the coating thickness is 250μm. The coating porosity is 15%.

[0040] (3) Put the prepared coating into the electromagnetic induction heating equipment, and heat the temperature to 300°C (to make the coating reach a molten or semi-molten state.

[0041] (4) Start the roll machine to make the coating pass through the roll at a constant speed, with a reduction of 37 μm.

[0042] (5) After 60 minutes of heat preservation, cool with the furnace; at this time, the porosity of the coating will drop to zero.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com