SiO2-Ag-SiO2 composite membrane for solar thermal power generation reflector and preparation method thereof

A technology of solar thermal power generation and reflectors, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve problems affecting reflectivity, affecting performance, and easy to be corroded, and achieves a simple process route , save maintenance costs and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

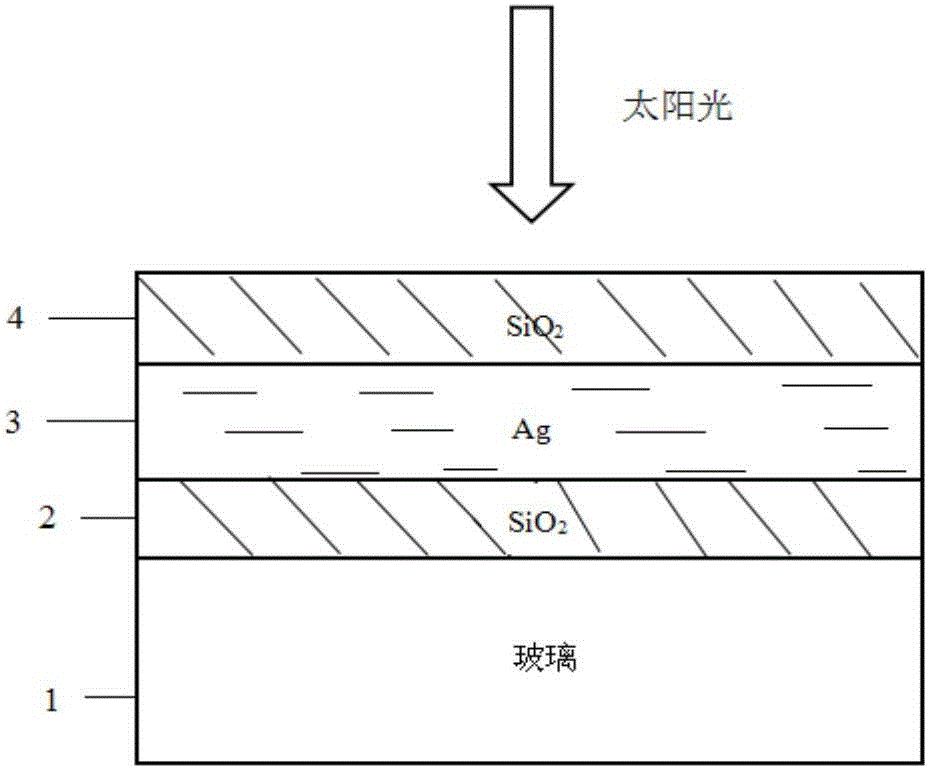

[0027] A kind of SiO used for solar thermal power mirror 2 -Ag-SiO 2 The preparation method of composite film comprises the following steps:

[0028]1) Select an ordinary glass slide (as the substrate), wash it with detergent several times (such as 2-5 times), wash off the impurities (dirty) on the surface, then rinse it with tap water, and then put it into deionized water for ultrasonic cleaning 20min, and finally put it into absolute ethanol [99.99% (mass), analytically pure] and ultrasonically clean it for 20min to obtain glass substrate 1; store the cleaned glass substrate in absolute ethanol [99.99% (mass), analytically pure] spare;

[0029] 2) Prepare a transition layer (or dielectric layer) on a glass substrate (or glass substrate): the method is to use radio frequency magnetron sputtering deposition method, SiO 2 The target size is The purity is 99.999wt%, the sputtering gas is high-purity argon with a volume fraction of 99.999%, and the vacuum degree of the sputt...

Embodiment 2

[0037] A kind of SiO used for solar thermal power mirror 2 -Ag-SiO 2 The preparation method of composite film comprises the following steps:

[0038] 1) Select an ordinary glass slide (as the substrate), wash it with detergent several times (such as 2-5 times), wash off the impurities (dirty) on the surface, then rinse it with tap water, and then put it into deionized water for ultrasonic cleaning After 20 minutes, put it into absolute ethanol [99.99% (mass), analytically pure] and ultrasonically clean it for 20 minutes to obtain a glass substrate; store the cleaned glass substrate in absolute ethanol [99.99% (mass), analytically pure] for later use ;

[0039] 2) Prepare a transition layer (or dielectric layer) on a glass substrate (or glass substrate): the method is to use radio frequency magnetron sputtering deposition method, SiO 2 The target size is The purity is 99.999wt%, the sputtering gas is high-purity argon with a volume fraction of 99.999%, and the vacuum degre...

Embodiment 3

[0045] A kind of SiO used for solar thermal power mirror 2 -Ag-SiO 2 The preparation method of composite film comprises the following steps:

[0046] 1) Select an ordinary glass slide (as the substrate), wash it with detergent several times (such as 2-5 times), wash off the impurities (dirty) on the surface, then rinse it with tap water, and then put it into deionized water for ultrasonic cleaning After 20 minutes, put it into absolute ethanol [99.99% (mass), analytically pure] and ultrasonically clean it for 20 minutes to obtain a glass substrate; store the cleaned glass substrate in absolute ethanol [99.99% (mass), analytically pure] for later use ;

[0047] 2) Prepare a transition layer (or dielectric layer) on a glass substrate (or glass substrate): the method is to use radio frequency magnetron sputtering deposition method, SiO 2 The target size is The purity is 99.999wt%, the sputtering gas is high-purity argon with a volume fraction of 99.999%, and the vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com