Preparation device, preparation method and application of plasma-modified glass fiber

A technology of glass fiber and preparation equipment, which is applied in the direction of fiber type, fiber treatment, ultrasonic/sonic fiber treatment, etc. It can solve the problems of poor mechanical properties and difficulty in modifying glass fiber, so as to expand the scope of use and increase hydrophilicity , Good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

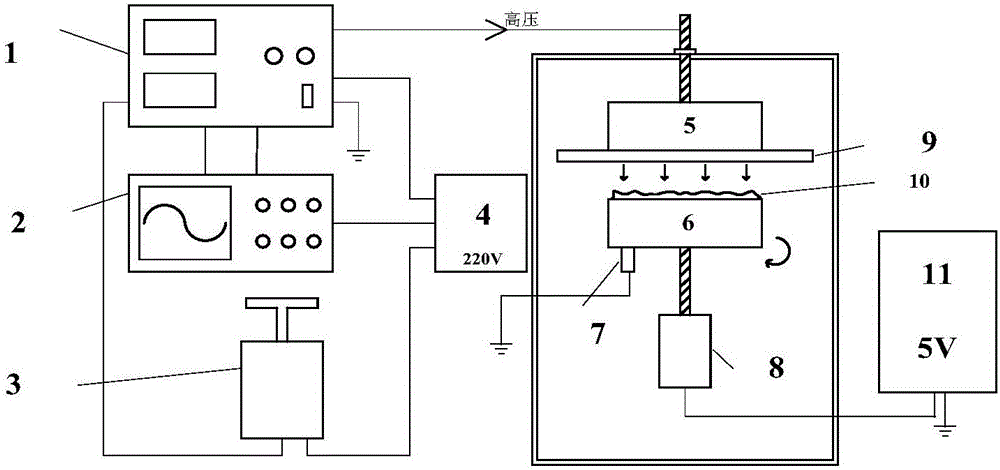

[0042] A preparation device for plasma modified glass fiber, such as figure 1 As shown, including pulse power supply device, discharge device and measuring device.

[0043] The pulse power supply device includes a pulse power supply 1 and a voltage regulator 3 connected to it, its function is to provide pulse voltage to the device, and observe the discharge phenomenon of the device during the step-up stage of the voltage regulator until uniform discharge.

[0044] Among them, the model of the pulse power supply device is CTP2000K;

[0045] The discharge device includes a high-voltage electrode 5 and a ground electrode 6. The high-voltage electrode 5 and the ground electrode 6 are arranged opposite to each other. The rotating motor 8 is connected to the ground electrode 6 to drive the ground electrode to rotate, which plays a role in increasing the probability of processing materials and making the materials evenly processed. ; The rotating motor 8 is connected to the 5V DC po...

Embodiment 1

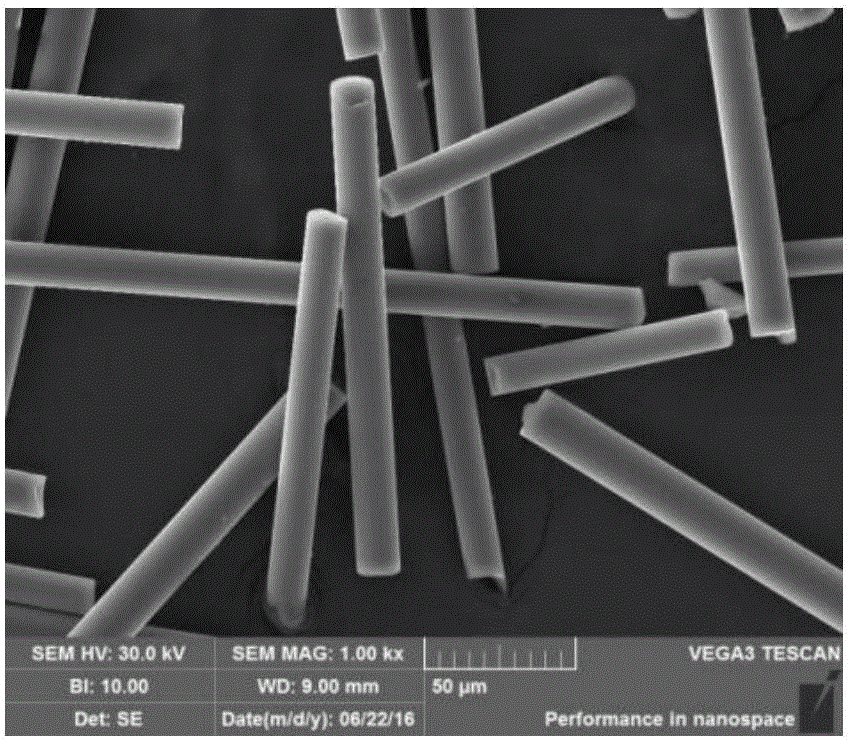

[0074] To prepare a plasma-modified glass fiber, first, put the glass fiber into an ultrasonic cleaning machine containing acetone and clean it for 0.5h to remove the dirt on the surface of the glass fiber; The finished glass fiber is dried in an oven until there is no moisture; the drying temperature is 120°C, and the drying time is 8h;

[0075] Then put the glass fiber into the discharge area of the preparation device, the discharge area is the area between the ground electrode 6 and the unilateral barrier medium, specifically, the glass fiber is tiled on the ground electrode 6, and the treatment is started. The parameters are: the working environment is air; the working pressure is atmospheric pressure; the working temperature is 25°C; the frequency of the pulse power supply is 11kHz; the peak value of the applied voltage is 20kV; the discharge power between the high voltage electrode and the ground electrode is 70W; processing time: 30s .

[0076] Utilize the glass fibe...

Embodiment 2

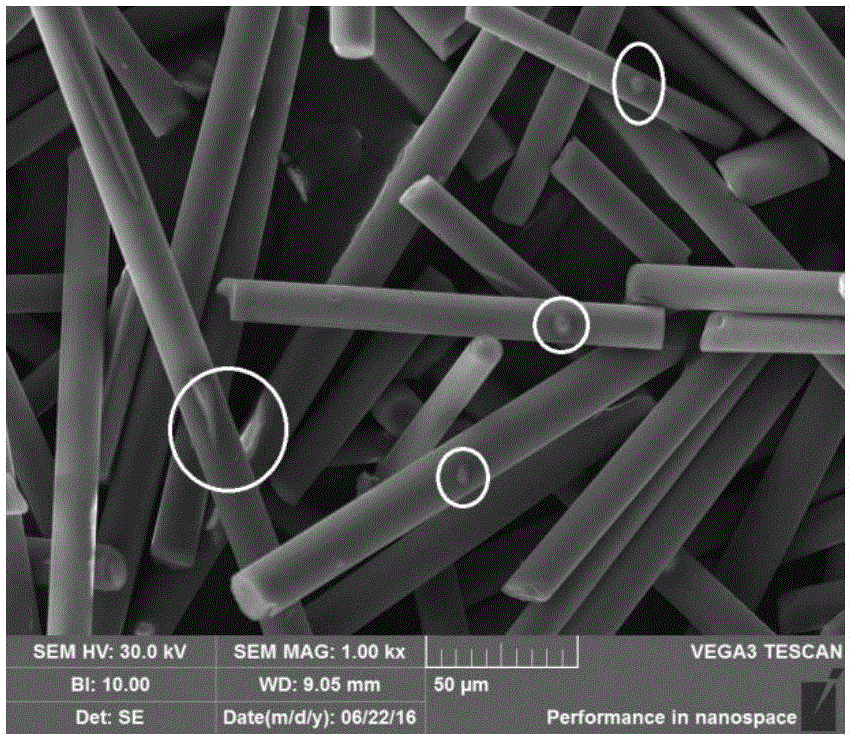

[0080] To prepare a plasma-modified glass fiber, first, put the glass fiber in an ultrasonic cleaning machine containing acetone and clean it for 1 hour to remove the dirt on the surface of the glass fiber; Dry the cleaned glass fibers in an oven until there is no moisture; the drying temperature is 130°C, and the drying time is 10 hours;

[0081] Then put the glass fiber into the discharge area of the preparation device, the discharge area is the area between the ground electrode 6 and the unilateral barrier medium, specifically, the glass fiber is tiled on the ground electrode 6, and the treatment is started. The parameters are: the working environment is air; the working pressure is under atmospheric pressure; the working temperature is 25°C; the frequency of the pulse power supply is 12kHz; the peak value of the applied voltage is 22kV; the discharge power between the high voltage electrode and the ground electrode is 71W; processing time: 540s .

[0082] Utilize the gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com