Electric-control spray nozzle type ammonia gas injection system used for tail gas treatment of diesel engine

A technology for exhaust gas treatment and injection system, which is applied in the direction of electronic control, exhaust gas treatment, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

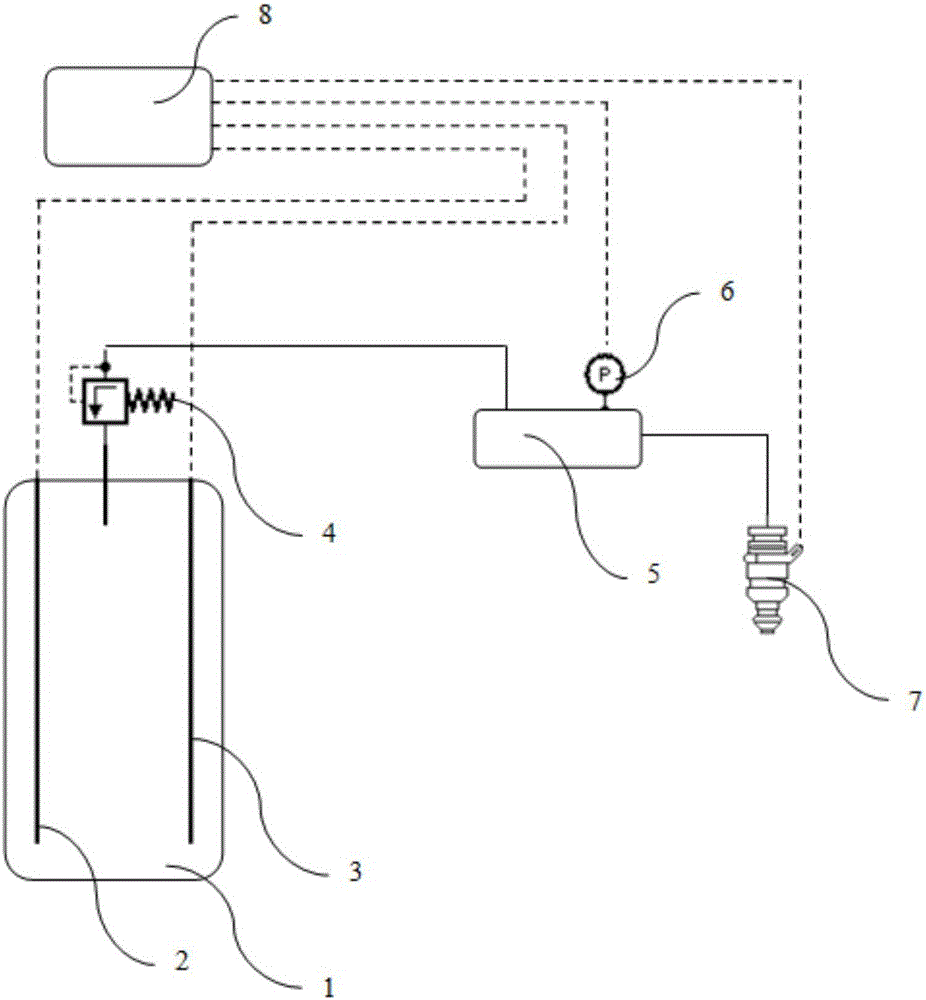

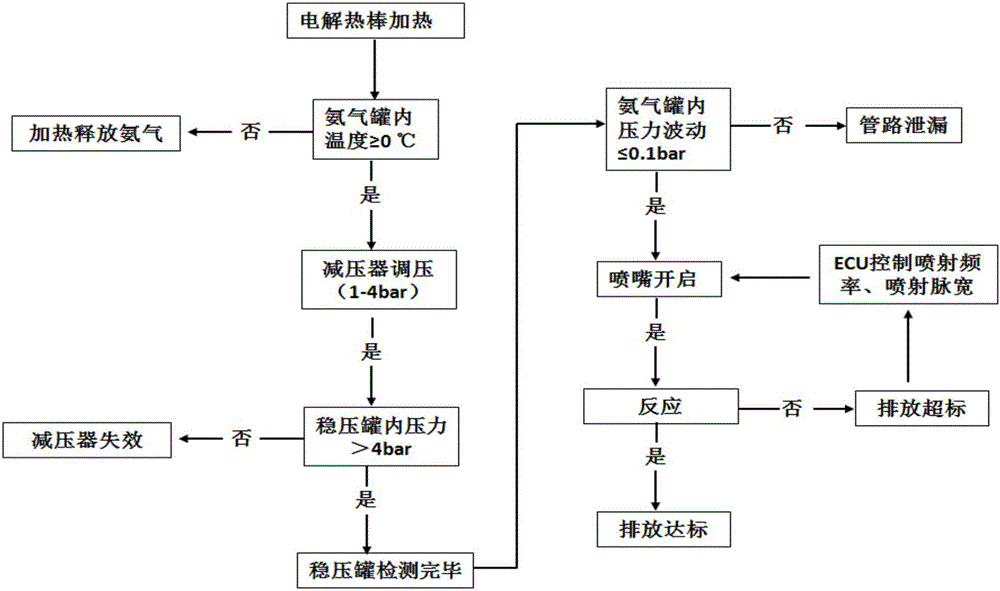

[0020] Such as figure 1 As shown, an electronically controlled nozzle-type ammonia injection system for diesel engine exhaust treatment includes a liquid ammonia tank 1, a liquid level temperature sensor 2, an electric heating rod 3, an ammonia pressure reducer 4, a surge tank 5, and a pressure Temperature sensor 6, electronically controlled ammonia nozzle 7, controller (ECU) 8. Among them, the liquid ammonia tank 1 is fixed on the frame of the whole vehicle. The liquid ammonia tank 1 stores liquid ammonia and the liquid ammonia tank 1 integrates a liquid level temperature sensor 2 and an electric heating rod 3. The liquid ammonia tank 1 is connected to the ammonia gas through a pipeline. The pressure reducer 4 and the ammonia gas pressure reducer 4 are connected to the surge tank 5 through pipelines, the surge tank 5 is fixed on the frame of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com