Multi-core fire-resistant power cable

A power cable and fire-resistant technology, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, insulated cables, etc., can solve the problems of single protective layer, poor corrosion resistance, and poor anti-interference performance, and achieve strong waterproof performance. High protection and anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

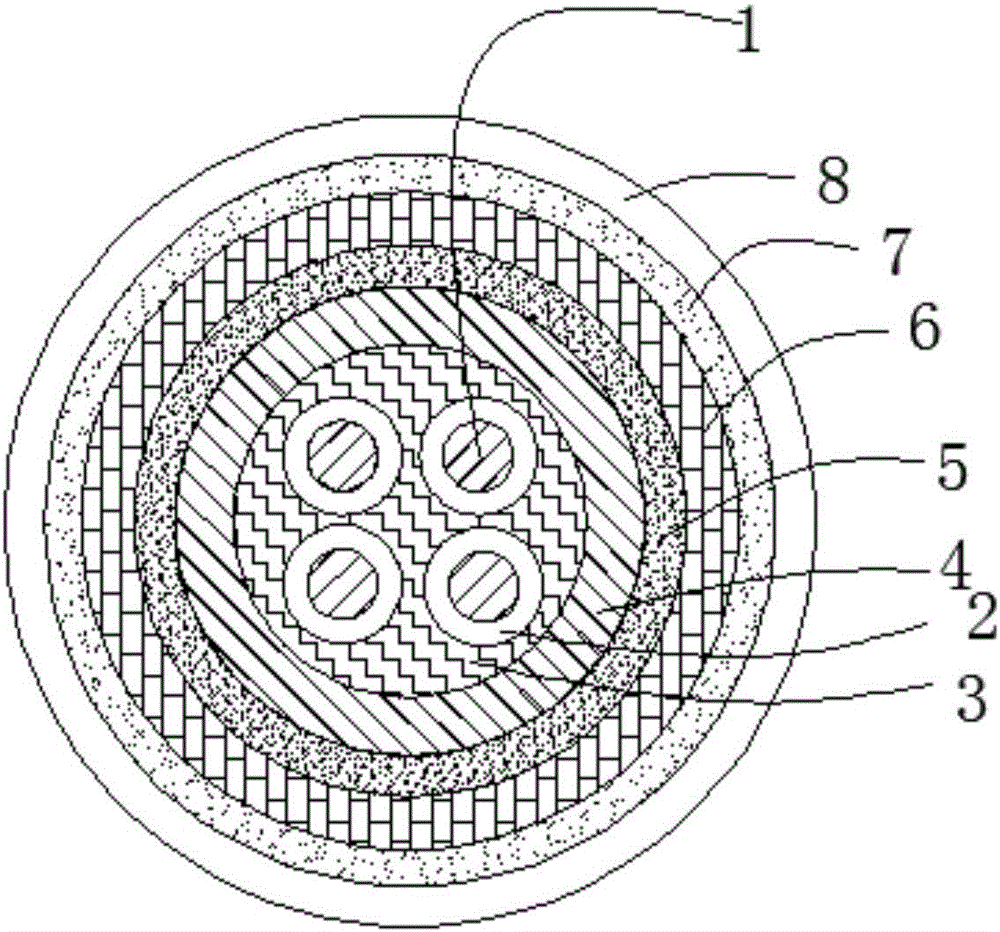

[0030] Embodiment 1: see figure 1 , a multi-core fire-resistant power cable according to the present invention, comprising a wire core, a filling layer 3, an outer shielding layer 4, an insulating layer 5 and a protective layer, the filling layer 3 wraps the wire core, and the outer shielding layer Layer 4 covers the filling layer 3, the insulating layer 5 covers the outer shielding layer 4, and the protective layer is a multi-layer structure, including a waterproof longitudinal water-blocking buffer layer 6, a fire-resistant first protective layer layer 7 and a corrosion-resistant second protective layer 8, the longitudinal water-blocking buffer layer 6 wraps the insulating layer 5, the first protective layer 7 wraps the longitudinal water-blocking buffer layer 6, the The second protective layer 8 covers the first protective layer 7; the longitudinal water-blocking buffer layer 6 includes a layer of gold cloth and a layer of water-blocking tape covered with gold cloth.

[00...

Embodiment 2

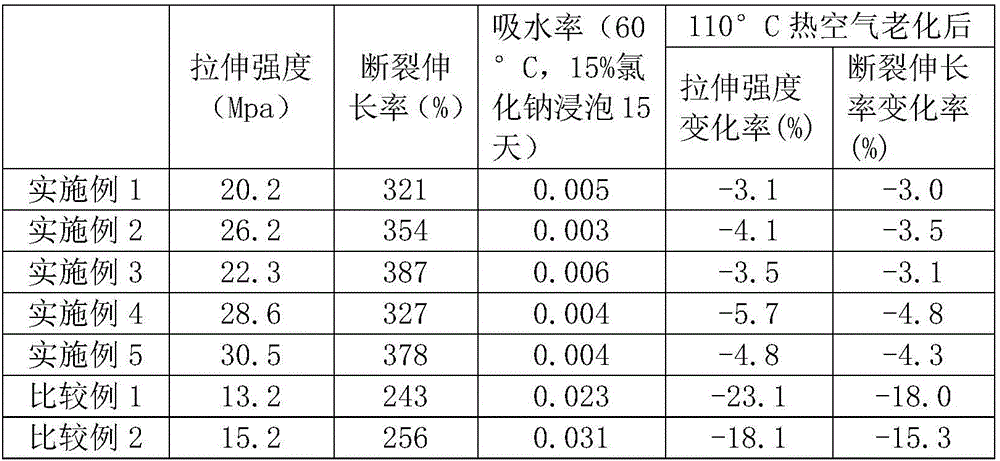

[0038] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated. The difference is that the first protective layer 7 is made of the following raw materials in parts by mass: 80 parts of acrylate rubber, 10 parts of silicone , 26 parts of polyurethane rubber, 8 parts of maleic anhydride grafted polyethylene, 60 parts of polyphenylene ether, 7 parts of microcrystalline paraffin, 11 parts of cumene diphenyl phosphate, 5 parts of naphthenic oil, 2 parts of calcium stearate 3 parts of zinc laurate, 1 part of lead dibasic phosphite, 12 parts of plasticizer WB350, 14 parts of magnesium hydroxide, 9 parts of antioxidant, 4 parts of silane coupling agent, 5 parts of accelerator CZ and zinc oxide 7 servings.

Embodiment 3

[0039] Embodiment 3: The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated. The difference is that the first protective layer 7 is made of the following raw materials in parts by mass: 76 parts of acrylate rubber, 20 parts of silicone , 22 parts of polyurethane rubber, 10 parts of maleic anhydride grafted polyethylene, 80 parts of polyphenylene ether, 10 parts of microcrystalline paraffin, 14 parts of isopropylphenyl diphenyl phosphate, 7 parts of naphthenic oil, 4 parts of calcium stearate 4 parts of zinc laurate, 3 parts of lead dibasic phosphite, 8 parts of plasticizer WB350, 11 parts of magnesium hydroxide, 6 parts of antioxidant, 3 parts of silane coupling agent, 2 parts of accelerator CZ and zinc oxide 6 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com