Application of naphthalene tetracarboxylic acid dianhydride derivative in inverted perovskite solar cell

A technology of naphthalene tetracarboxylic dianhydride and solar cells, which is applied in the application field of naphthalene tetracarboxylic dianhydride derivatives in inverted perovskite solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

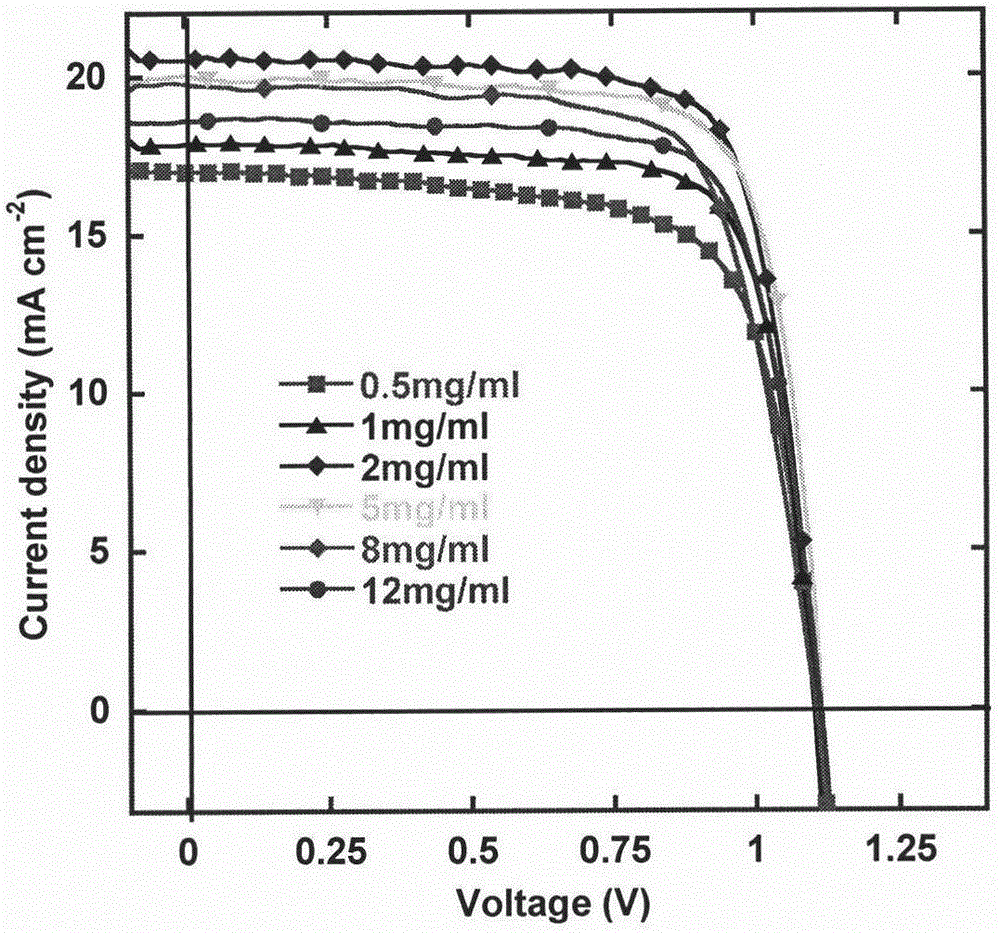

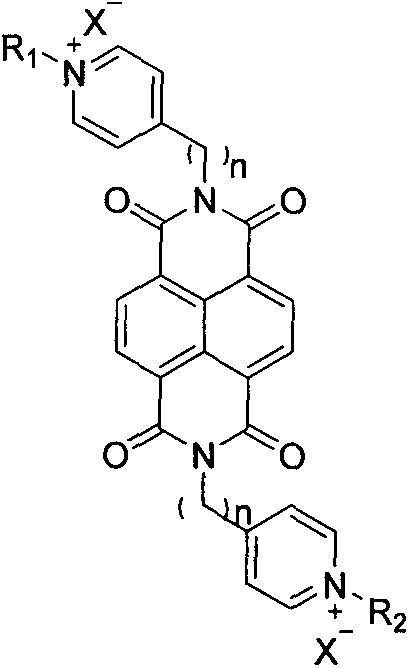

[0018] N,N′-bis(1-n-hexylpyridin-1-ium-4-ylmethyl)naphthalene-1,8,4,5-bis(dicarboximide) dibromide was used as perovskite The interface modification layer of PCBM / Ag in solar cells has the following molecular structural formula:

[0019]

[0020] Step 1: ITO substrate cleaning

[0021] Use a mixture of zinc powder and dilute hydrochloric acid to etch a 1.5cm x 1.5cm ITO substrate, and then ultrasonically clean the etched ITO in deionized water, acetone, and isopropanol for 15 minutes, and finally blow it with nitrogen. Dry and irradiate in UV-ozone for 15 minutes.

[0022] Step 2: Device Preparation

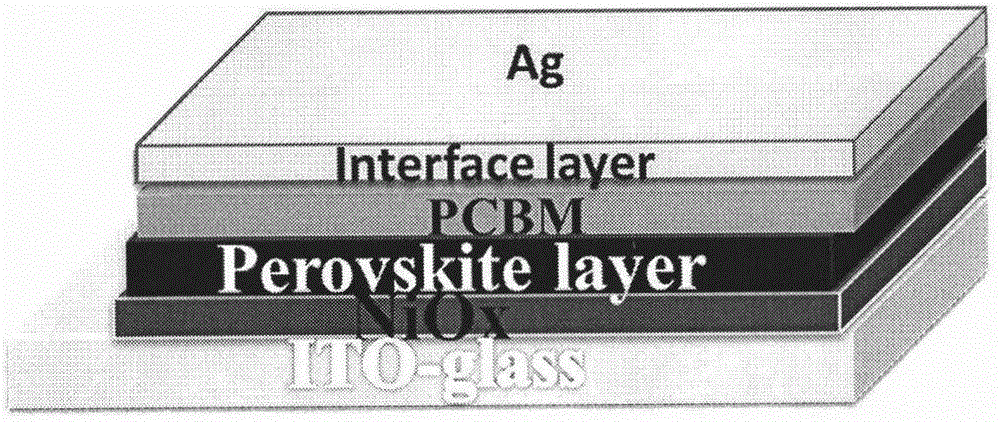

[0023] (1) Preparation of modified layer device ITO / NiOx / Perovskite Layer / PCBM / Interface layer / Ag:

[0024] First (FAI: PbI2) 0.1 (CsI: PbI2) 0.1 (MAI: PbI2) 0.65 (MAI: PbCl2) 0.15 was dissolved in the solvent of GBL: DMSO=7: 3 (V / V), stirred for 3 hours and set aside; Drop the perovskite precursor solution into the ITO / NiOx film, rotate at 1000r / min for 20s, rotate at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com