Ordered catalyst layer and preparation and application thereof

A catalytic layer, catalyst technology, applied in nanotechnology, electrical components, battery electrodes, etc. for materials and surface science, to achieve the effect of improving utilization, reducing usage, and shortening conduction paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

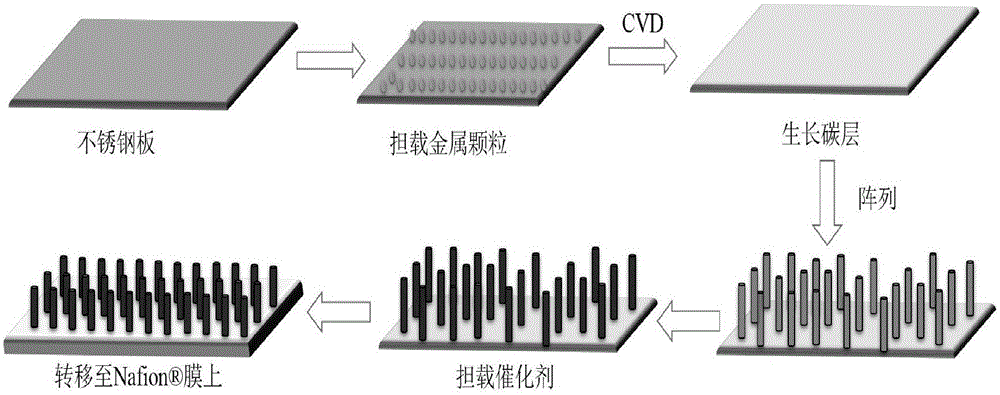

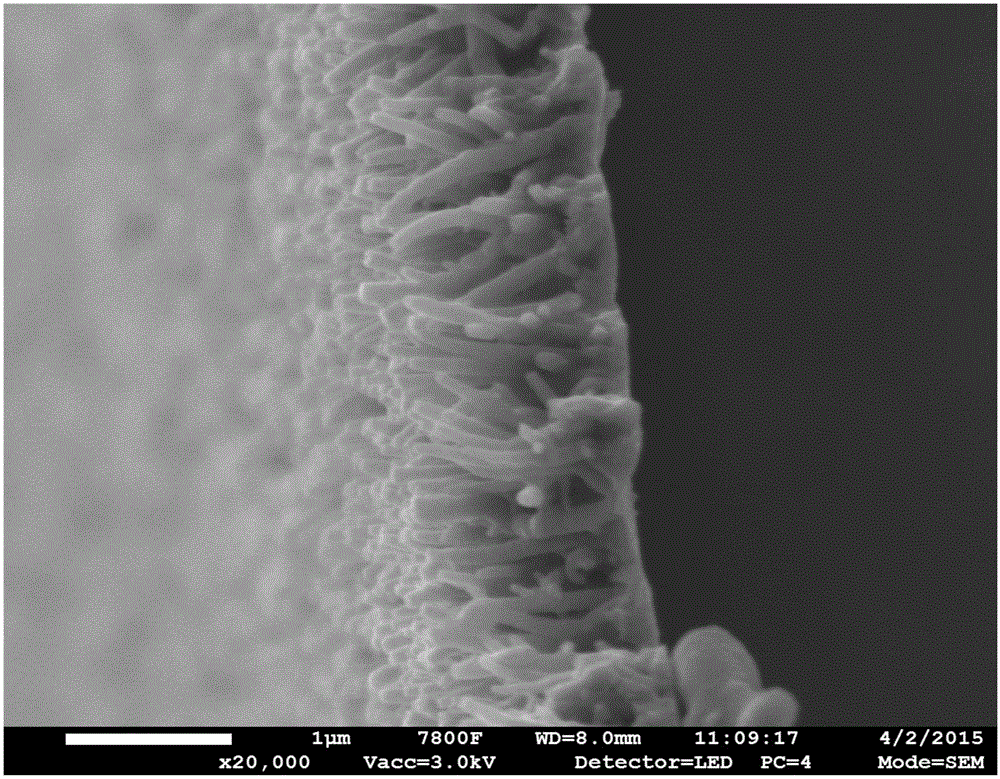

[0024] Step 1: FeCo alloy catalyst loaded on stainless steel surface by magnetron sputtering (co-sputtering FeCo catalyst, deposition conditions: under Ar atmosphere at 20°C, sputtering power 200W, vacuum degree 1.0Pa, sputtering time 6min, Fe : Co (atomic ratio) = 1:1, catalyst thickness: ~ 20nm), and then prepare a carbon layer on the stainless steel surface by CVD (CH 4is the carbon source, the volume ratio of CH 4 :H 2 =1:4, flow rate 50mL min -1 , temperature: 700°C, radio frequency: 200W, reaction time: 25min). Then in situ polymerize the ordered PPy array on the surface of the carbon layer by potentiostatic polymerization (deposition potential 0.7V, temperature: 25°C, reaction time: 20min, reaction solution: 0.2M phosphate buffer + 0.1M p-toluenesulfonate Sodium acid + 0.1M pyrrole monomer), the PPy array has the characteristics of growing perpendicular to the surface of the carbon layer and has a length of 1.2 μm and a diameter of 80 nm.

[0025] Step 2: Deposit Ag...

Embodiment 2

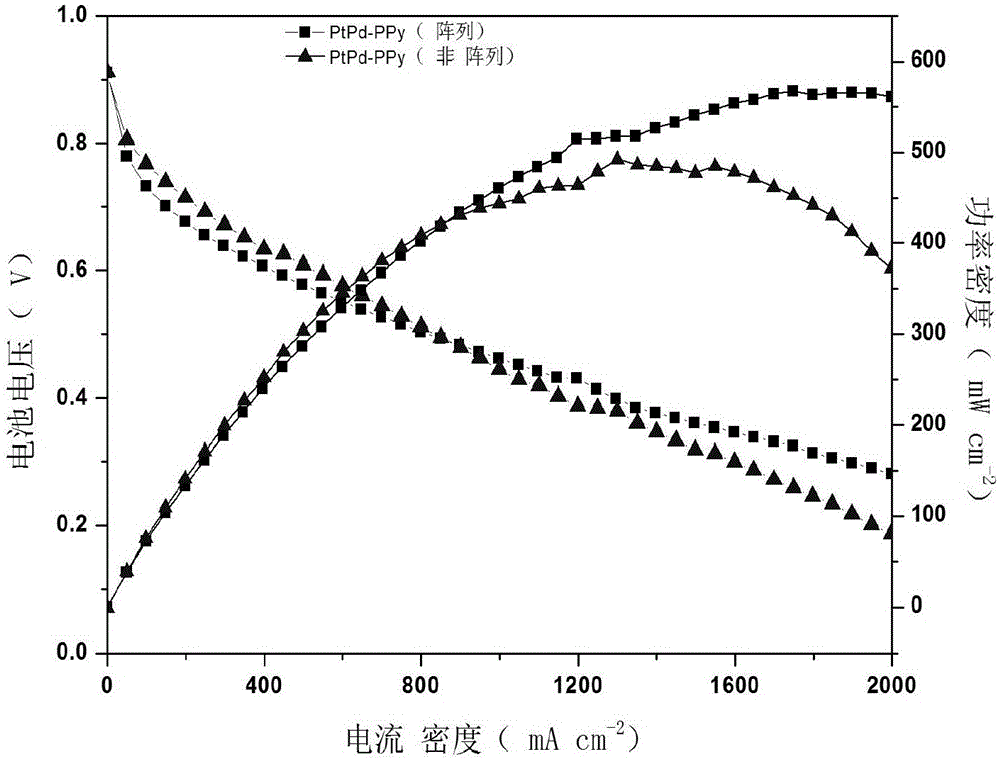

[0028] Take the PPy nanorod array prepared in step 1 of Example 1, and first pass magnetron sputtering Pd catalyst (under Ar atmosphere at 20°C, sputtering power 200W, vacuum degree 1.0Pa, sputtering time Pd: 8min) , and then put the sample in H 2 Saturated 100mL with K 2 PtCl 4 (20mg) ethanol solution, after reduction reaction for 1.5h, the PPy array with the catalyst was transferred onto the Nafion membrane, and used as a single-cell cathode, wherein the cathode catalyst loading (Pt: 0.101mg / cm 2 ,Pd:50μg / cm 2 );

[0029] The anode is commercialized GDE (0.4mg Pt / cm 2 ), used in proton exchange membrane fuel cells. Battery temperature: 65°C, PH 2 =PO 2 =0.05MPa, gas flow: H 2 =50 sccm,O 2 =100sccm, Humidity: H 2 / O 2 =100% / 100%, Nafion membrane.

[0030] image 3 is the i_V curve of the single-cell test when the PtPd-PPy ordered electrode is used as the cathode. The single-cell performance of the electrode prepared here is better than that of the previously pr...

Embodiment 3

[0034] Take the PPy nanorod array prepared in step 1 in Example 1.

[0035] Magnetron sputtering Cu metal particles on the PPy nanowire array (Cu: 5min, other sputtering conditions are the same as in Example 1, Cu: 25.245 μg / cm 2 ), by K with 0.1M 2 PtCl 4 The solution was subjected to a displacement reaction to obtain a PtCu-PPy array (Pt: 60.5 μg / cm 2 ).

[0036] The prepared electrode is carried out half-cell test, and the test condition is (N 2 saturated 0.5M H 2 SO 4 , scanning speed 50mV / s, scanning range: -0.241V-0.959V vs SCE)

[0037] Figure 4 It is the CV diagram of PtCu-PPy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com