AC asynchronous motor with circumferential windings

A technology for AC asynchronous motors and windings, applied to asynchronous induction motors, prevention/reduction of eddy current loss in winding heads, shape/style/structure of winding conductors, etc., can solve the problem of large amount of electromagnetic wires, increased weight, and magnetic field utilization Reduce problems, achieve good regularity and consistency, improve reliability and life, and improve power and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

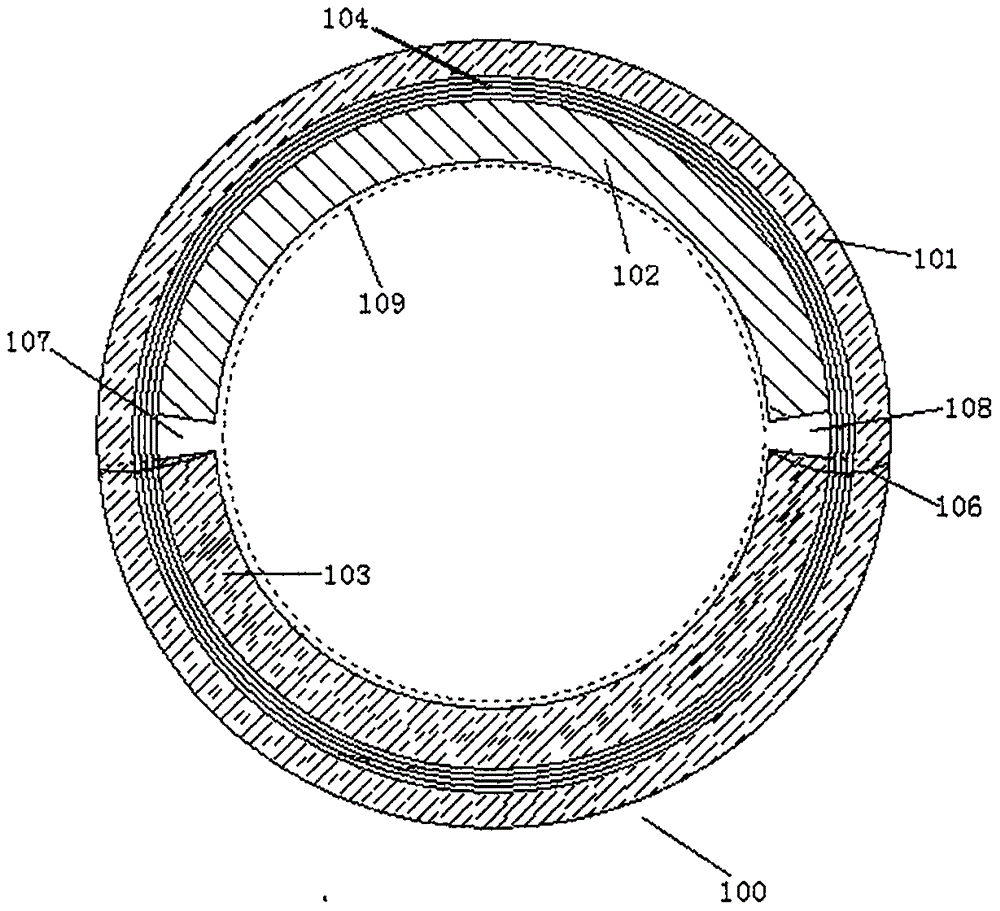

[0086] figure 1 It is a schematic diagram of the stator axial section structure of a single-phase circumferential winding AC asynchronous motor;

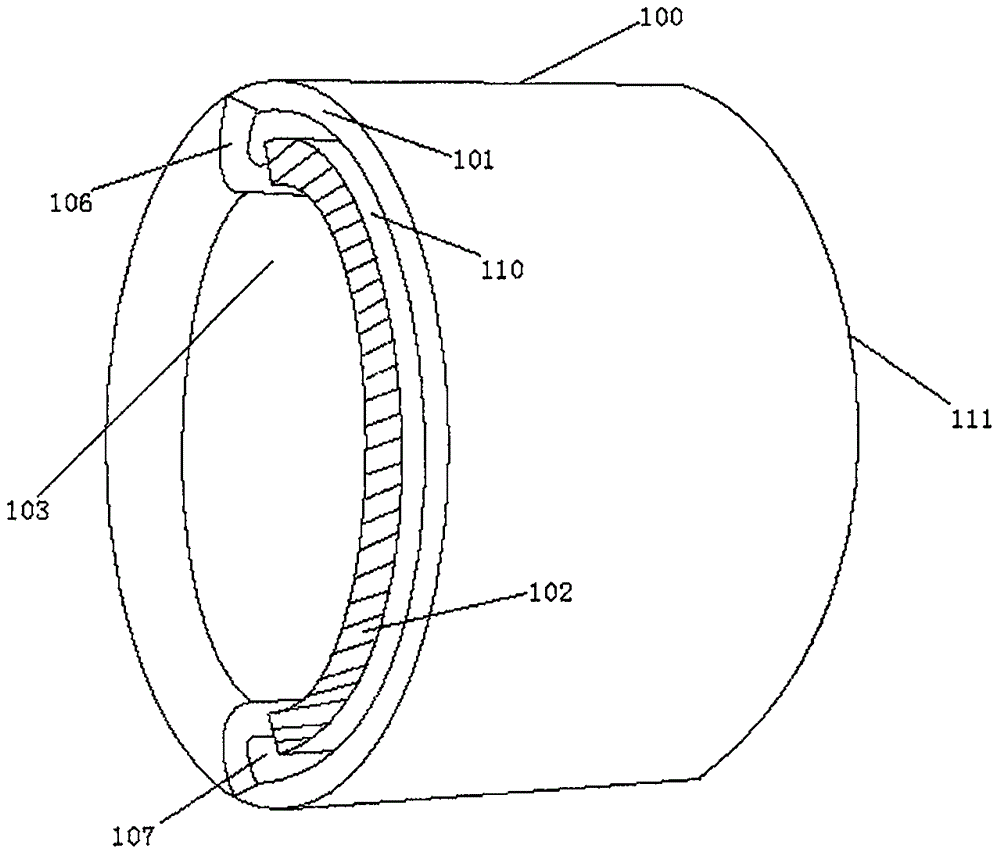

[0087] figure 2 It is a schematic diagram of the three-dimensional structure of the stator of the single-phase circumferential winding AC asynchronous motor;

[0088] The AC motor with circumferential winding includes rotor, stator core, stator winding, casing and supporting parts, as the stator of single-phase circumferential winding motor such as figure 1 and figure 2 As shown, the outer stator type stator core 100, stator winding 104, the rotor is an asynchronous motor rotor (not shown in the figure), the stator winding 104 is a circumferential winding, which is a circular coil structure coaxial with the motor, the stator The magnetic core includes a cylindrical magnetic core 101, a stator magnetic pole 102, a stator magnetic pole 103, and a magnetic circuit connecting body connecting the axial end of the cylindrical magneti...

Embodiment 2

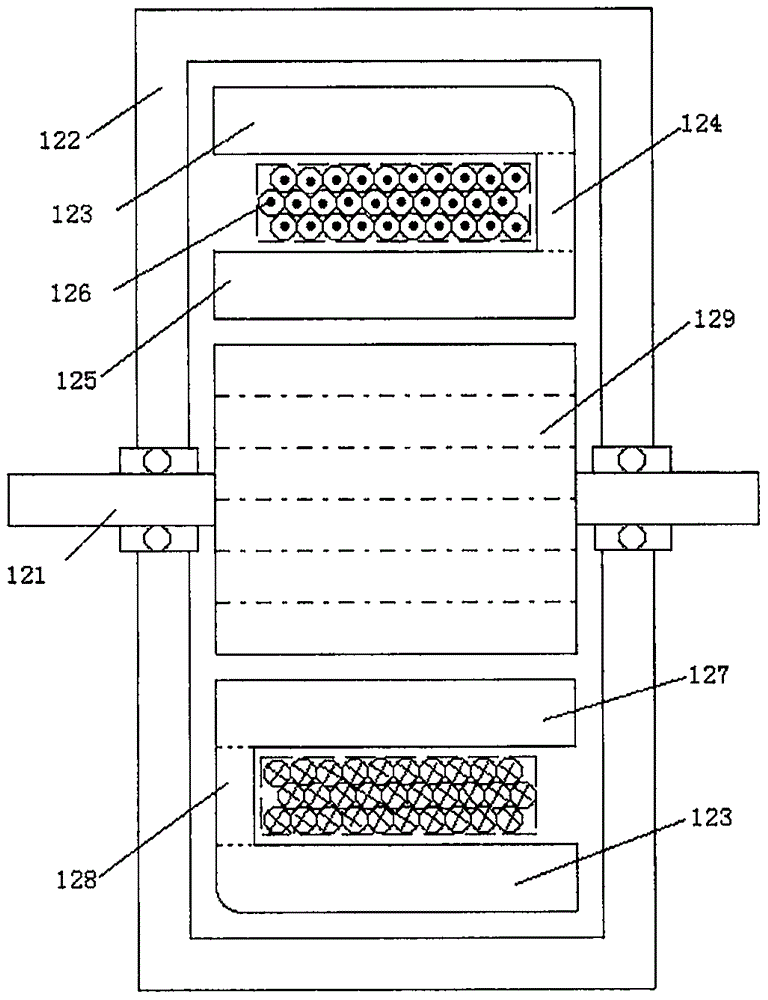

[0092] Such as image 3 and Figure 4 shown, where image 3 It is a side section view of a single-phase circumferential winding AC asynchronous motor, Figure 4 Expand the diagram for its stator.

[0093] The alternating current asynchronous motor of this circumferential winding comprises: outer stator type stator magnetic core 123, stator winding 126 and casing 122 and support member, rotor is the rotor of asynchronous motor, and stator winding 126 is the circumferential winding of circumferential direction, is the same as the motor The circular coil structure of the shaft center, the stator magnetic core comprises cylindrical magnetic core 123, stator magnetic poles (such as 125, 127), stator magnetic poles (such as 125) and the cylindrical magnetic core (123) axial end and stator magnetic pole ( Such as 125) a magnetic circuit connecting body (such as 124) connected at one end, a cylindrical magnetic core (123) with an integrated structure or a split combined structure w...

Embodiment 3

[0111] This embodiment takes a three-phase motor as an example to describe an AC asynchronous motor that adopts stator axially separated phases and circumferential windings with the same angle as the rotor core.

[0112] Figure 5 It is the three-phase stator phase ratio diagram of the AC asynchronous motor with three-phase circumferential winding and axial split phase, Figure 6 is the schematic diagram of the three-dimensional structure of the motor rotor, Figure 7 It is a schematic diagram of the side section structure of the motor.

[0113] Such as Figure 5 As shown, the three-phase stator of the motor is named A, B, and C three phases. In the figure, 145 indicates the A-phase stator core, 146 indicates the B-phase stator core, and 147 indicates the C-phase stator core. Select each phase core The phase comparison of the three-phase stator magnetic core is carried out at the midpoint of the distance between adjacent magnetic poles. The dotted line 140 in the figure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com