Low-oxalic-acid food or beverage and preparation method thereof

A food and drink technology, applied in the field of low oxalate food or drink and its preparation, can solve the problems of poor effect and high technical difficulty, and achieve the effect of good food and happiness, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 low oxalate tea instant beverage

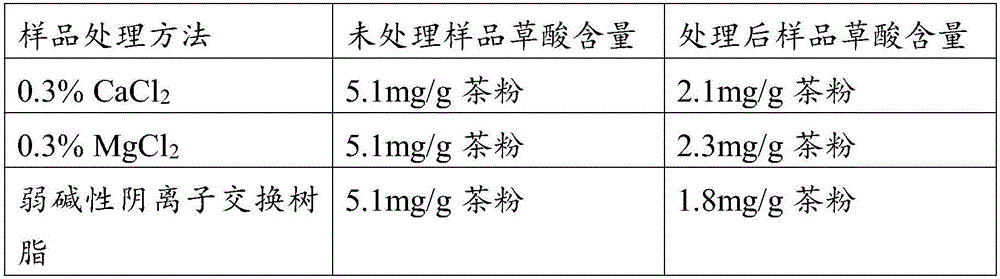

[0032] Take the green tea instant beverage as an example to illustrate the embodiment, select 1 kg of dry green tea, add 10 kg of deionized water after crushing, place it on an electric furnace, control the water temperature at 60-70 ° C for 30 minutes, filter through a filter cloth to remove slag, and add 0.2% tannin Enzyme, treated at 35°C for 2h, adding 0.3% (w / w) food grade CaCl 2 , (additional determination plus 0.3% (w / w) food grade MgCl 2 Treatment and the experimental group treated with weakly basic anion exchange resin) Stir to dissolve and mix well, let stand for 30min, heat to 60°C, dissolve the reversible precipitate for 10min, and centrifuge to remove the heat-insoluble oxalate precipitate in the extraction solution, while ensuring that the tea leaves Other active substances are not destroyed, and the filtrate is concentrated by reverse osmosis membrane, and the concentration pressure is 10kg / cm 2 , when the...

Embodiment 2

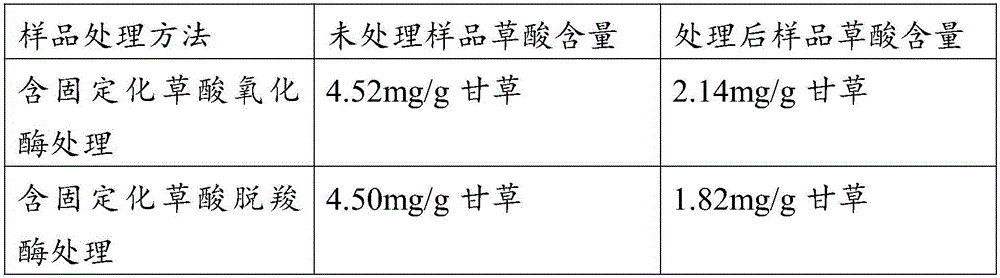

[0035] Example 2 Low oxalate soy milk

[0036] After 100g of soybeans are soaked and saturated with water, grind them into bean paste with 1kg of deionized water, adjust the pH value to 4.0 with citric acid, add 0.1g of oxalate decarboxylase (20000U / g), keep warm at 30°C and keep stirring, react for 30min, 60min , and 120min. After the reaction, the bean paste is separated and removed from the bean dregs to obtain soybean milk with a solid concentration of about 8%, immediately heated and boiled and maintained for 5 minutes, concentrated to a solid content of about 15% with a vacuum thin film evaporator, and finally dried by a spray dryer (inlet temperature 195° C., outlet temperature 80° C.) to obtain soybean flour. Soybean powder is made into instant soymilk powder products of different flavors and specifications through subsequent seasoning (such as adding soda powder to neutralize citric acid to ensure that the final product has a suitable taste and no unpleasant sour tas...

Embodiment 3

[0039] Example 3 Low Oxalate Buckwheat Bread

[0040] (1) Mix 300g of buckwheat flour, 700g of wheat flour, oxalate oxidase (1000U), 15g of white sugar, 30g of margarine, and 4g of salt according to a certain ratio and mix evenly. At the same time, no oxalate oxidase was set as a control, and the rest of the conditions were the same.

[0041](2) Then activate the yeast with an appropriate amount of water (warm water at 30°C for 20 minutes), and add it to the mixed flour.

[0042] (3) Use an appropriate amount of water to blend the flour into a dough. When the surface of the dough is not sticky, has strong elasticity and is uniform, it indicates that the dough has reached the best state, and the blending can be completed.

[0043] (4) Divide the dough into small noodle pieces of the same size, then knead them into rounds, make them into desired shapes according to requirements, and put them into an oiled baking tray, keeping proper intervals.

[0044] (4) Put the molded bread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com