Preparation method of antibacterial and pollution-resistant renewable ultra-filtration membrane

An ultrafiltration membrane and anti-pollution technology, which is applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of low water flux of polysulfone ultrafiltration membranes, reduced membrane surface adsorption capacity, microbial contamination, etc., to achieve increased The hydrophilicity of the membrane, the improvement of antibacterial and anti-pollution ability, and the effect of reducing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

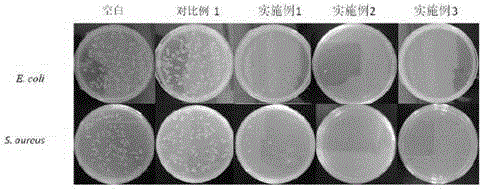

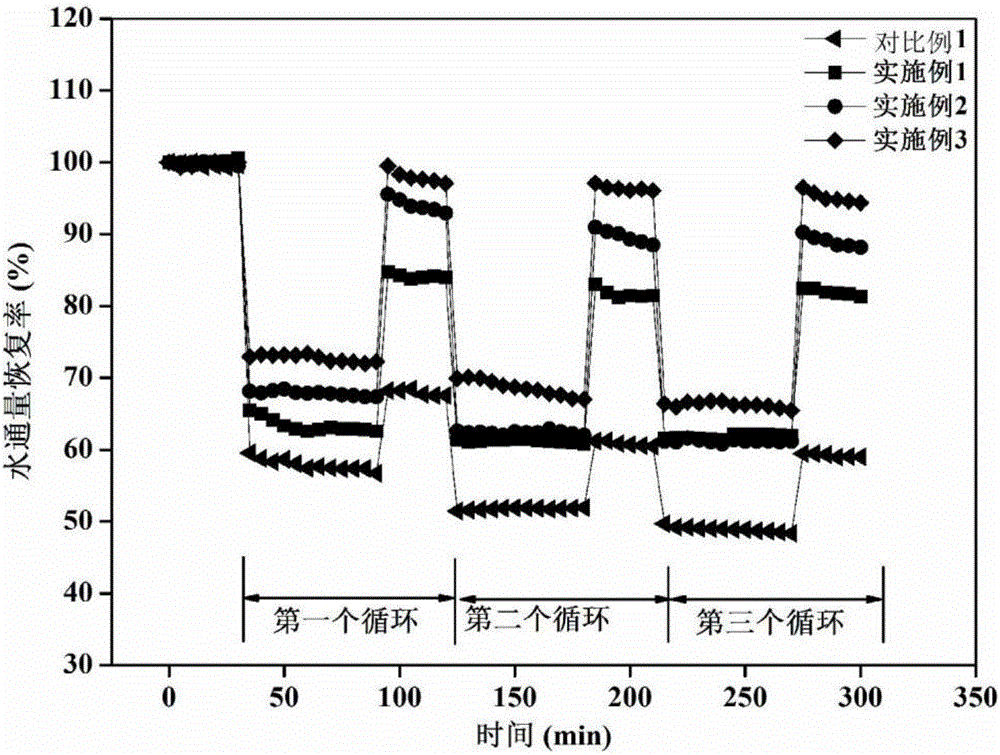

Embodiment 1

[0037] (1) Dissolve 9.5g of polysulfone and 0.5g of amphiphilic polymer A in N-methylpyrrolidone, stir fully at 60°C until completely dissolved, and prepare a solution with a mass fraction of 18%, and obtain a uniform solution after degassing at room temperature. A stable casting solution; the amphiphilic polymer A is polyethylene glycol-modified phenolphthalein polyethersulfone, and the specific structure is as follows,

[0038] Wherein, m / (m+n)=20%, molecular weight is 160000;

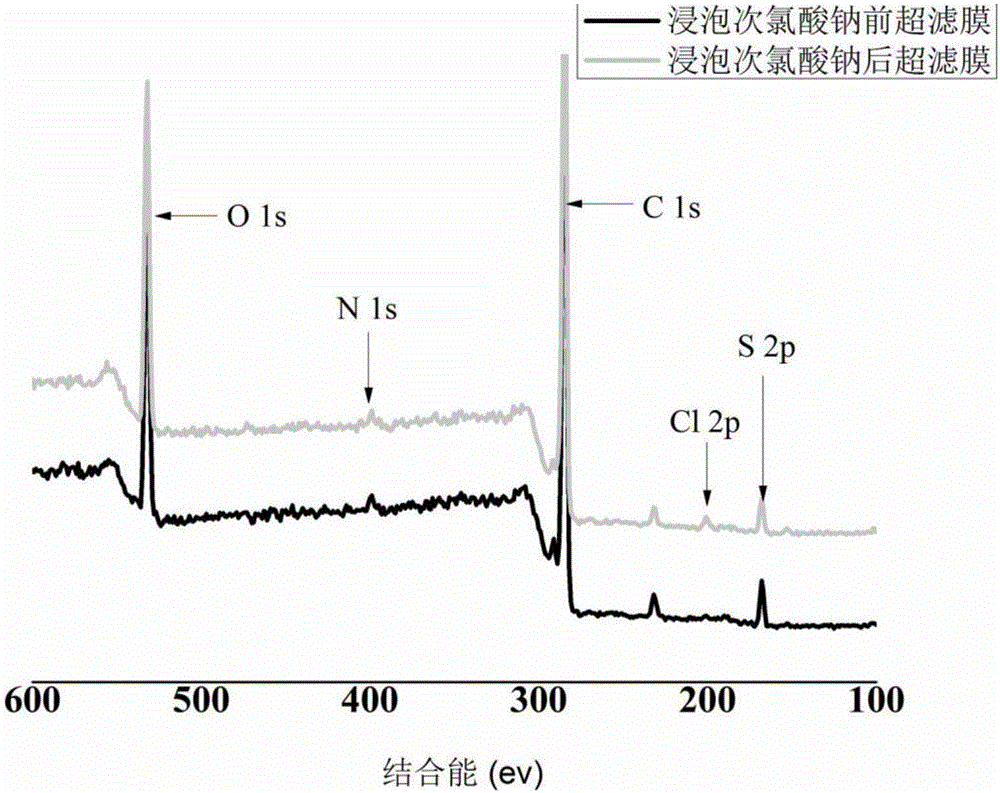

[0039] (2) Pour the casting solution on a glass plate, and use a spatula to uniformly form a flat film with a blade gap of 150 mm, quickly put it into deionized water, and soak in deionized water for 24 hours to remove residual solvent. Take out the ultrafiltration membrane and soak it in 1% sodium hypochlorite solution at 20°C for 1 hour, wash away the residual sodium hypochlorite with deionized water until the starch / potassium iodide solution does not turn blue, and obtain a renewable ultrafiltra...

Embodiment 2

[0047](1) Dissolve 9.0g of polysulfone and 1.0g of amphiphilic polymer A in N-methylpyrrolidone, stir well at 60°C until completely dissolved, and prepare a solution with a mass fraction of 18%, and obtain a uniform solution after degassing at room temperature. A stable casting solution; the amphiphilic polymer A is polyethylene glycol-modified phenolphthalein polyethersulfone, and the specific structure is as follows,

[0048] Wherein, m / (m+n)=80%, molecular weight is 80000;

[0049] (2) Pour the casting solution on a glass plate, and use a spatula to uniformly form a flat film with a blade gap of 150 mm, quickly put it into deionized water, and soak in deionized water for 24 hours to remove residual solvent. Take out the ultrafiltration membrane and soak it in 2% sodium hypochlorite solution at a temperature of 35°C for 2 hours, wash away the residual sodium hypochlorite with deionized water until the starch / potassium iodide solution does not turn blue, and obtain a renewa...

Embodiment 3

[0055] (1) Dissolve 8.5g of polysulfone and 1.5g of amphiphilic polymer A in N-methylpyrrolidone, stir fully at 60°C until completely dissolved, and prepare a solution with a mass fraction of 18%, and obtain a uniform solution after degassing at room temperature. A stable casting solution; the amphiphilic polymer A is polyethylene glycol-modified phenolphthalein polyethersulfone, and the specific structure is as follows,

[0056] Wherein, m / (m+n)=50%, molecular weight is 100000;

[0057] (2) Pour the casting solution on a glass plate, and use a spatula to uniformly form a flat film with a blade gap of 150 mm, quickly put it into deionized water, and soak in deionized water for 24 hours to remove residual solvent. Take out the ultrafiltration membrane and soak it in a 3% sodium hypochlorite solution at a temperature of 20°C for 1 hour, wash away the residual sodium hypochlorite with deionized water until the starch / potassium iodide solution does not turn blue, and obtain a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com