Tail gas cyclic utilizing device during calcium carbonate processing

A technology of exhaust gas circulation and calcium carbonate, applied in swirling devices, cleaning methods and utensils, removal of smoke and dust, etc., can solve the problem of dust flying at the discharge port, and achieve the effect of not consuming energy, reducing flying losses, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

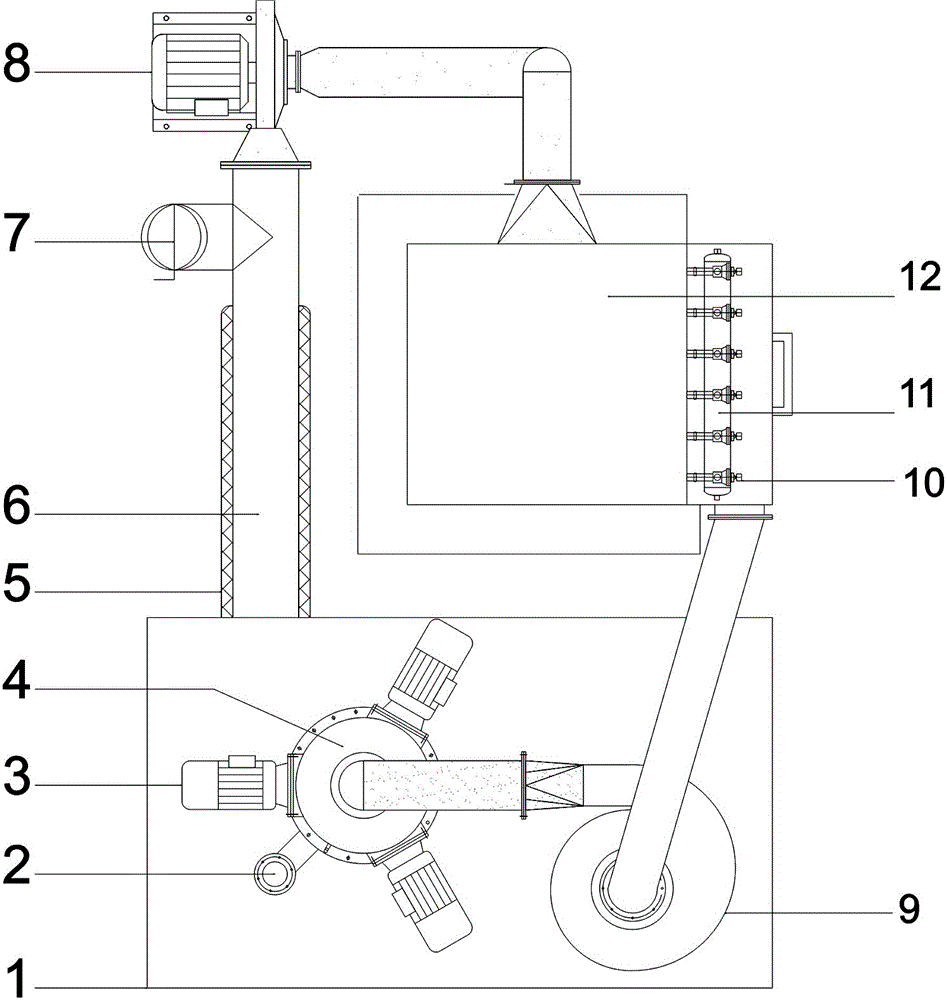

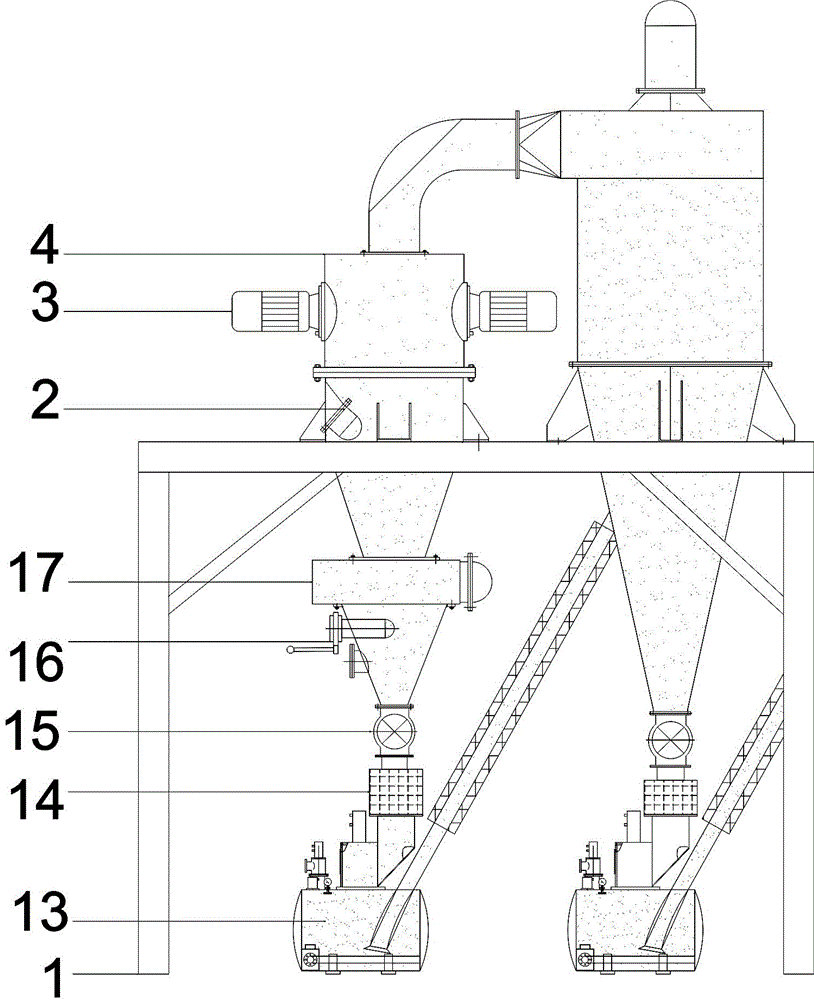

[0017] Such as figure 1 , figure 2 As shown, a tail gas recycling device in calcium carbonate processing includes a frame 1, and the frame 1 is equipped with a classifier 3, a centrifugal fan 8, a dust collector 12, and a cyclone separator 9, and the classifier 3 passes through the return air duct 6 Connect the centrifugal fan 8, the centrifugal fan 8 is connected to the dust collector 12 through the pipeline, the dust collector 12 is connected to the cyclone separator 9 through the return air pipeline 17, the cyclone separator 9 is connected to the classifier 3 through the pipeline, and the cyclone separator 9 is connected to the warehouse pump 13 .

[0018] The return air duct 17 is connected to the bin pump 13 through the rotary unloading valve 15 and the iron remover 14 .

[0019] The return air duct 17 is provided with a secondary elutriation damper 16 .

[0020] The classifier 3 is provided with a classifying inlet 2, and a classifying chamber 4 is arranged inside it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com