Defoaming device and method for electrochemical wastewater treatment system

A technology of defoaming device and treatment system, which is applied in the direction of degassed water/sewage treatment, foam dispersion/prevention, etc. It can solve the problems of incomplete elimination of defoaming device and complicated structure, so as to avoid clogging, ensure defoaming effect, Avoid the effect of water and foam seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

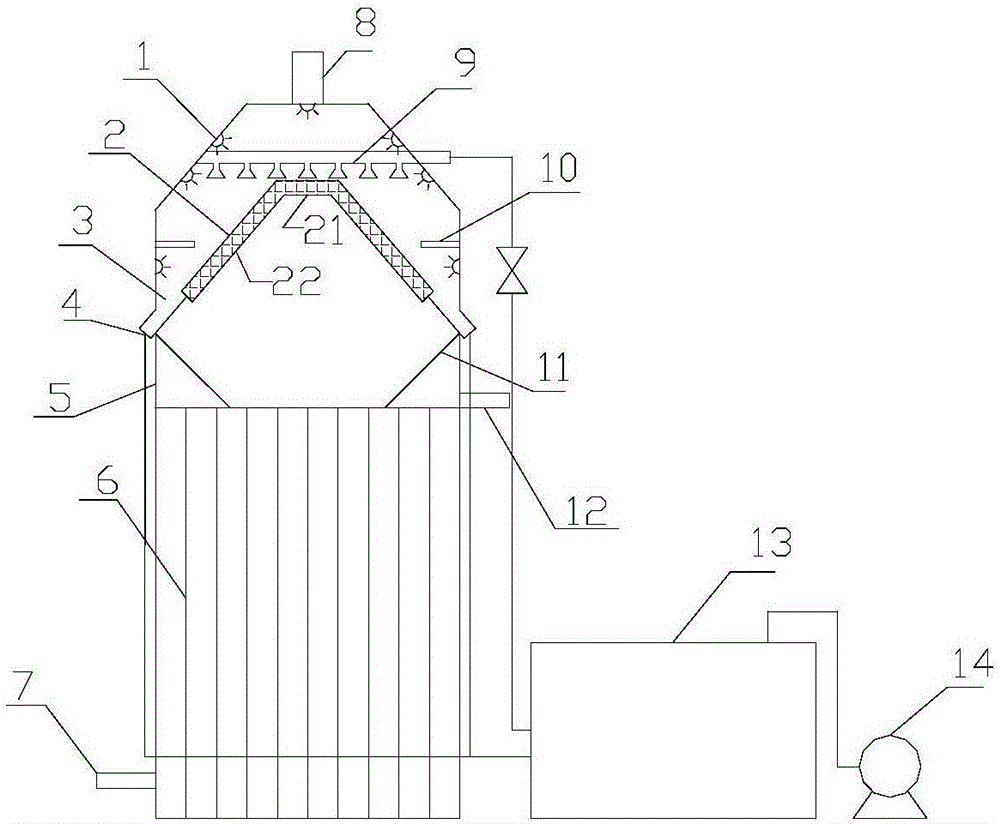

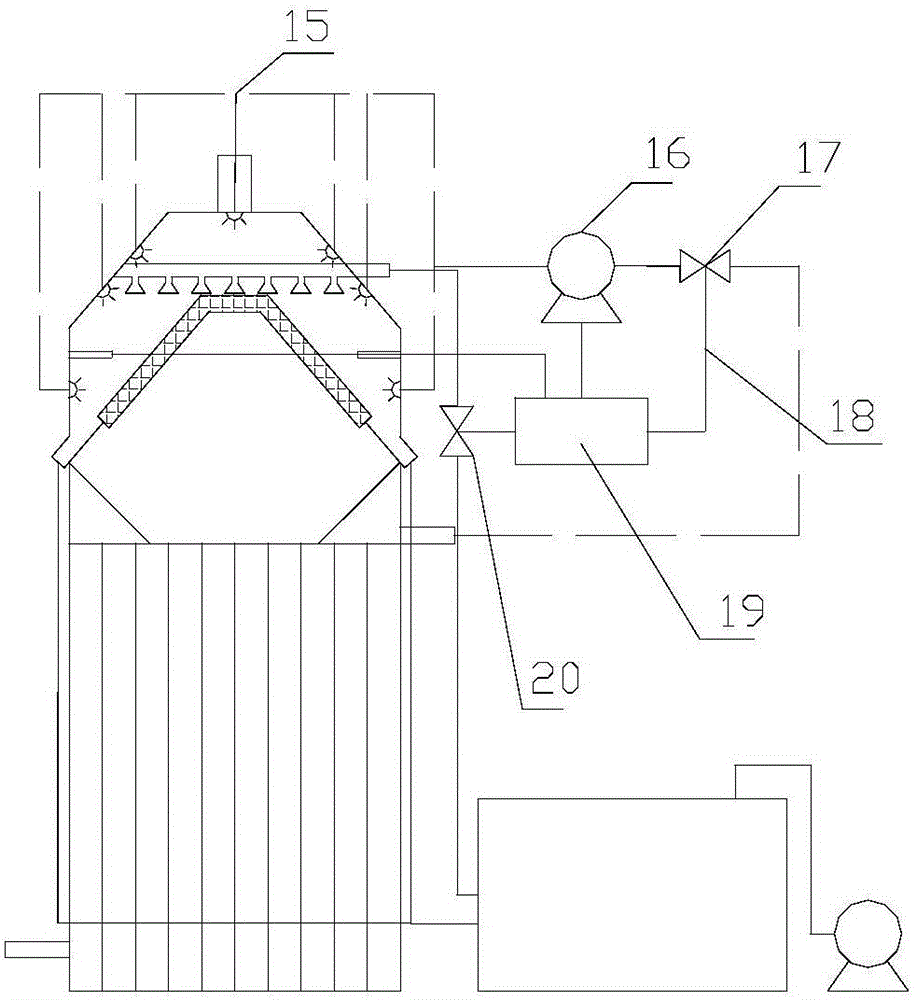

[0067] Such as Figure 1 ~ Figure 3 Shown, a kind of defoaming device comprises electrolyzer 5, and electrolyzer 5 is conventional electrolyzer, and electrolyzer built-in electrode plate 6, the bottom of electrolyzer connects water inlet pipe 7, and top connects outlet pipe 12.

[0068] A defoaming baffle 2 is turned upside down above the electrolytic cell. The defoaming baffle is turned upside down above the electrolytic cell in the shape of a truncated cone, and is composed of a top plate 21 and a side plate 22. The top plate is a circular plate, and the side plates surround the top plate and connect with the top plate. The angle between the junction of the side plate and the top plate is an obtuse angle, preferably 120°-135°, and the vertical height between the top plate and the bottom edge of the side plate is 1 / 6-1 / 4 of the height L of the electrolytic cell.

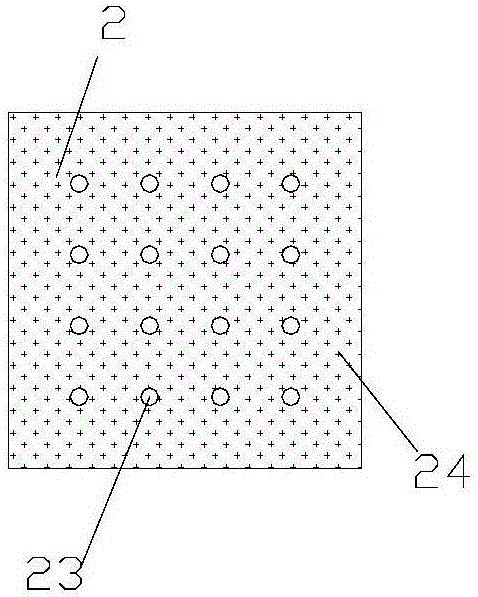

[0069] The schematic diagram of the defoaming baffle is as follows: image 3 As shown, a number of through holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com