High-efficiency slow release scale inhibitor and preparation method thereof

A scale inhibitor and slow-release technology, applied in the field of high-efficiency slow-release scale inhibitor and its preparation, can solve the problems of poor effect, shortened equipment service life, low scale inhibition rate, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

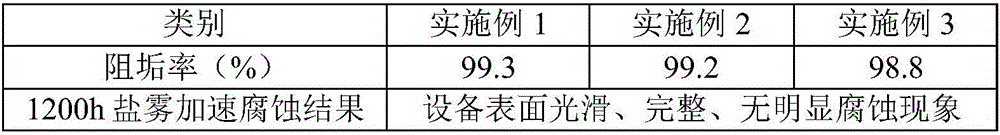

Examples

Embodiment 1

[0026] 1. A high-efficiency slow-release scale inhibitor, which is formed by mixing components A and B, and component A includes the following components in parts by weight: 20 parts of acrylic acid sulfonic acid, 20 parts of citrate, polyaspartic acid 12 parts of acid, 13 parts of sodium gluconate, 6 parts of dimethyl sulfoxide, 0.5 parts of n-hexylamine, and 2 parts of inorganic salt are dissolved in soybean slurry, and the concentration of soybean slurry is 200g / L;

[0027] Component B includes the following components in parts by weight: 20 parts of polymers of polyacrylamide and / or acrylamide derivatives, 30 parts of organic phosphoric acid scale inhibitors and 100 parts of water;

[0028] A component and B component are mixed according to the mass ratio of 4:1.

[0029] Wherein, the citrate is sodium citrate, and the beans are a mixture of green beans, soybeans, black beans, red beans and peas.

[0030] The inorganic salt is a mixture of calcium salt, iron salt and magn...

Embodiment 2

[0038] 1. A high-efficiency slow-release scale inhibitor, which is formed by mixing components A and B, and component A includes the following components in parts by weight: 10 parts of acrylic acid sulfonic acid, 30 parts of citrate, polyaspartic acid Prepared by dissolving 10 parts of acid, 15 parts of sodium gluconate, 10 parts of dimethyl sulfoxide, 0.1 part of n-hexylamine, and 1 part of inorganic salt in soybean slurry, the concentration of which is 100 g / L;

[0039] Component B includes the following components in parts by weight: 15 parts of polymers of polyacrylamide and / or acrylamide derivatives, 45 parts of organic phosphoric acid scale inhibitors and 100 parts of water;

[0040] A component and B component are mixed according to the mass ratio of 5:1.

[0041] Wherein, the citrate is potassium citrate, and the beans are a mixture of lima beans and soybeans.

[0042] The inorganic salt is calcium salt.

[0043] The organic phosphoric acid scale inhibitor is a mixt...

Embodiment 3

[0050] 1. A high-efficiency slow-release scale inhibitor, which is formed by mixing components A and B, and component A includes the following components in parts by weight: 30 parts of acrylic acid sulfonic acid, 10 parts of citrate, polyaspartic acid Prepared by dissolving 15 parts of acid, 10 parts of sodium gluconate, 1 part of dimethyl sulfoxide, 1 part of n-hexylamine, and 3 parts of inorganic salt in soybean slurry, the concentration of which is 300g / L;

[0051] Component B includes the following components in parts by weight: 30 parts of polymers of polyacrylamide and / or acrylamide derivatives, 15 parts of organic phosphoric acid scale inhibitors and 100 parts of water;

[0052] A component and B component are mixed according to the mass ratio of 3:1.

[0053] Wherein, the citrate is a mixture of sodium citrate and potassium citrate, and the beans are a mixture of soybeans, black beans, red beans and peas.

[0054] The inorganic salt is a mixture of iron salt and magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com