Threaded treatment device for desalinating high-salinity wastewater based on molybdenum alloy squirrel cage flameproof motor

A technology of explosion-proof motor and molybdenum alloy, which is applied in electromechanical devices, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high power consumption and low reverse osmosis concentrated water treatment capacity, and reduce process costs , obvious energy-saving effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The method of the present invention will be described below through specific examples to make the technical solution of the present invention easier to understand and grasp, but the present invention is not limited thereto. The experimental methods described in the following examples, unless otherwise specified, are conventional methods; the reagents and materials, unless otherwise specified, can be obtained from commercial sources.

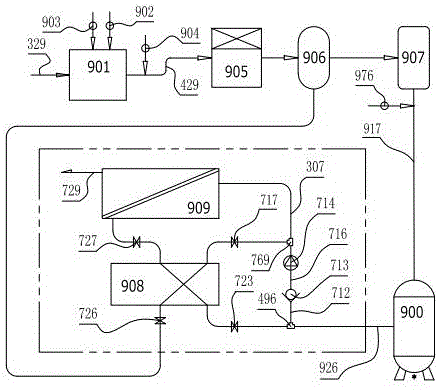

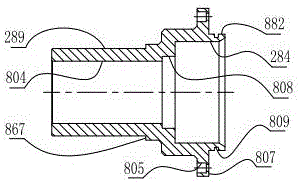

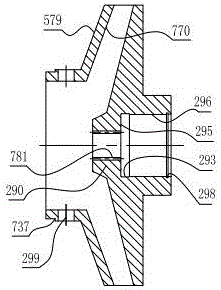

[0054] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 14 , Figure 20 and Figure 27 Among them, molybdenum alloy squirrel cage explosion-proof motor high-salt wastewater desalination screw treatment device, including: clarifier 901, filter tank 905, sodium ion exchanger 906, carbon remover 907, three-stage set fine filter 900 and screw energy recovery inverter Permeation assembly, the screw energy recovery reverse osmosis assembly includes a pressure exchange screw booster pump 908 and a reverse osmosis component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com