Medium alumina ceramic ball and preparation method thereof

A production method and technology of aluminum porcelain, applied in the field of aluminum ceramic balls and their production, can solve the problems of limited production demand of high aluminum ceramic balls, influence of production demand of medium aluminum ceramic balls, inability to achieve the performance of high aluminum ceramic balls, etc. , to achieve the effect of being conducive to the healthy and sustainable development of the economy, low cost and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can help those skilled in the art to understand the present invention more comprehensively, but cannot limit the present invention in any way.

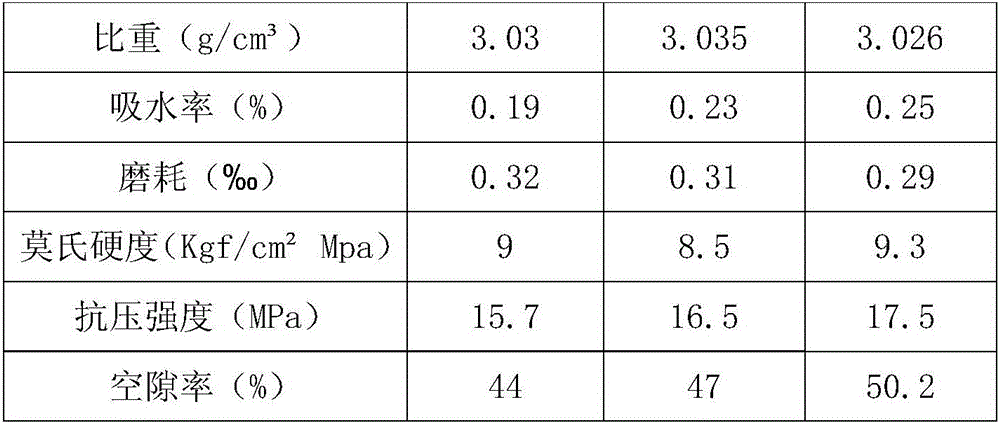

[0026] A medium-aluminum ceramic ball is mainly made of low-quality bauxite powder, kaolin, barite, dolomite, potassium albite feldspar, recycling material, bricks, calcium sulfate, mineral fiber, carbon fiber and black earth ore. Wherein, the specific content of the above raw materials in Examples 1-5 is shown in Table 1.

[0027] Raw material and content (unit: kg) of aluminum ceramic ball in the embodiment 1-5 of table 1

[0028] raw material Example 1 Example 2 Example 3 Example 4 Example 5 Low-quality cooked aluminum ore powder 400 410 450 490 500 Kaolin 20 21 25 29 30 Barite 20 21 25 29 30 dolomite 20 21 25 29 30 potassium albite feldspar 10 11 15 19 20 Recycling material 200 210 280 290 300 bricks 300 310 350 39...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com