Preparing method of coal fulvic acid with high purity

A fulvic acid, high-purity technology, applied in the direction of organic chemistry, can solve the problems of low extraction rate and complicated process, and achieve the effects of reducing molecular weight, simplifying operation and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

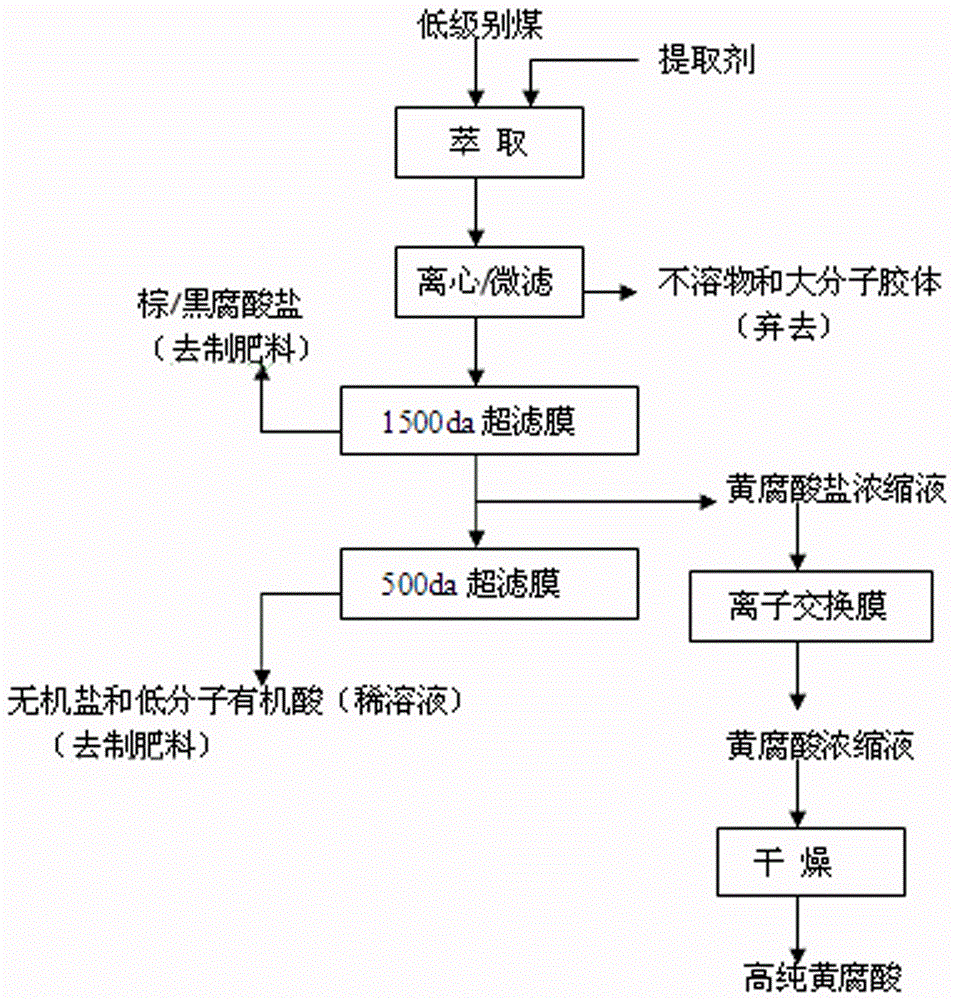

Method used

Image

Examples

Embodiment 1

[0027] Weigh 100 g of Yunnan Shiping peat with a particle size of 200 mesh and put it in a stainless steel reactor, add 800 ml of 0.5 mol / L of KOH, and use an ultrasonic generator produced by Crecson Ultrasonic Co., Ltd. to feed in ultrasonic waves with a power of 500 W and a frequency of 80 KHz. React at 80°C for 1 hour; centrifuge the obtained suspension with a high-speed centrifuge of the type 2-16KL / 2-16P produced by Huobajiu Industrial Co., Ltd., the centrifuge speed is 10000r / min, discard the residue, and obtain humic acid Potassium humate crude solution; under the condition of 0.4MPa pressure and operating flow rate of 10L / min, the potassium humate crude solution was passed through a microfiltration membrane with a pore size of 50 μm, the filtrate was collected, and the intercepted residue was discarded; under the pressure of 1.0MPa, the The filtrate is sequentially pumped into ultrafiltration membranes with molecular weights of 1500da and 500da, and the retentate after ...

Embodiment 2

[0029] Weigh and crush 100 g of Yunnan Shiping peat with a particle size of 200 mesh in a stainless steel reactor, add 600 ml of 0.5 mol / L KOH, and the rest of the steps are the same as in Example 1 to obtain fulvic acid powder. After inspection, the FA content of the powder is 98.3% ( dry basis).

Embodiment 3

[0031] Weigh and crush 100 g of Yunnan Shiping peat with a particle size of 200 mesh in a stainless steel reactor, add 1200 ml of 0.5 mol / L KOH, and the rest of the steps are the same as in Example 1 to obtain fulvic acid powder. After inspection, the FA content of the powder is 98.5% ( dry basis).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com