Method for preparing PVDF modified three-dimensional braided carbon fiber structural damping composite material

A three-dimensional weaving and composite material technology, applied in the direction of carbon fiber, etc., can solve the problems of affecting the use, easy to delaminate, and sacrificing the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0019] (1) Prepare PVDF solution according to the following mass ratio: dissolve polyvinylidene fluoride (PVDF) in dimethylformamide (DMF) solvent to prepare a solution of PVDF, wherein polyvinylidene fluoride in the solution of PVDF The mass ratio of (PVDF) to dimethylformamide (DMF) is 1:20. Stir magnetically in a water bath at 65°C for 1 h to fully dissolve PVDF in DMF to obtain a uniformly mixed solution.

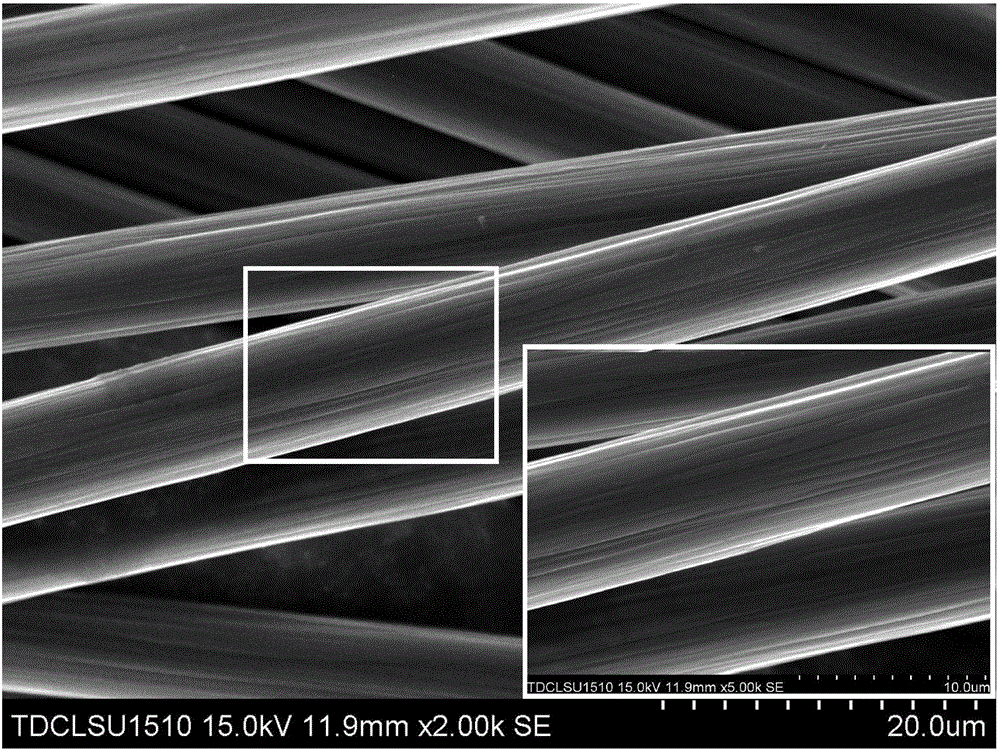

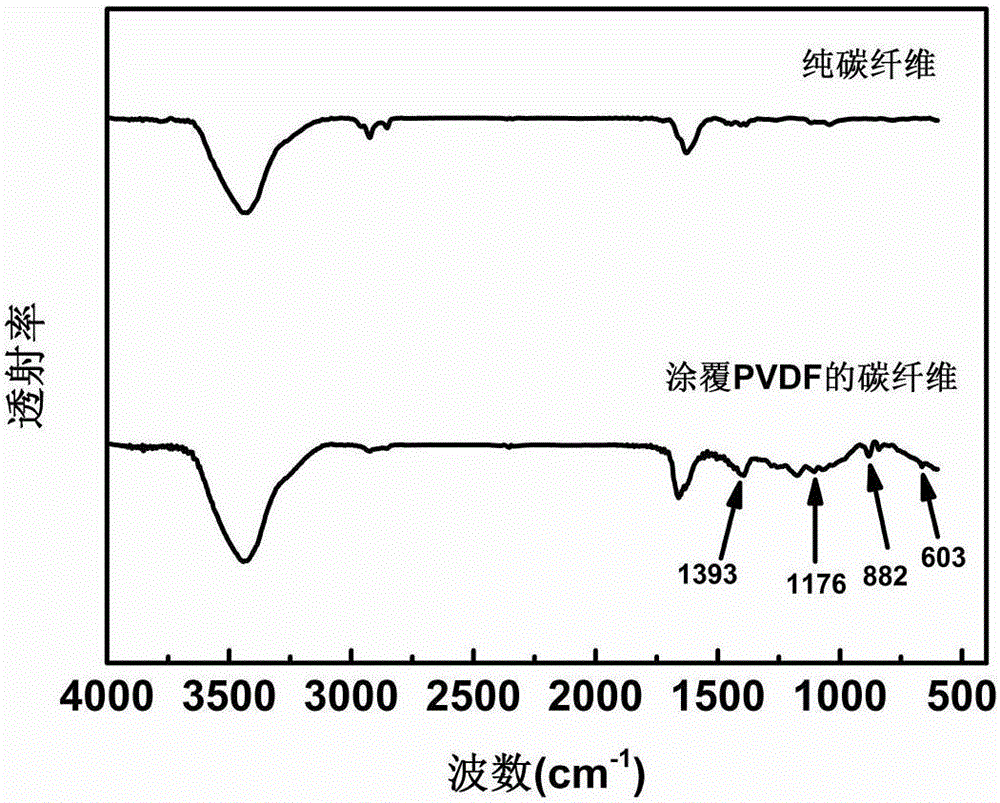

[0020] (2) Pretreatment of three-dimensional woven carbon fiber: the fiber fabric is treated with 5wt% (NH 4 ) 2 HPO 4 The solution was boiled for 1 h, then rinsed with deionized water for three times, and ultrasonicated with deionized water for 30 min to remove the residue on the surface of the fiber (NH 4 ) 2 HPO 4 Impurities, and dried in an oven at 120 ° C for 3 hours, the scanning image of the three-dimensional woven carbon fiber before coating PVDF is as follows figure 1 shown.

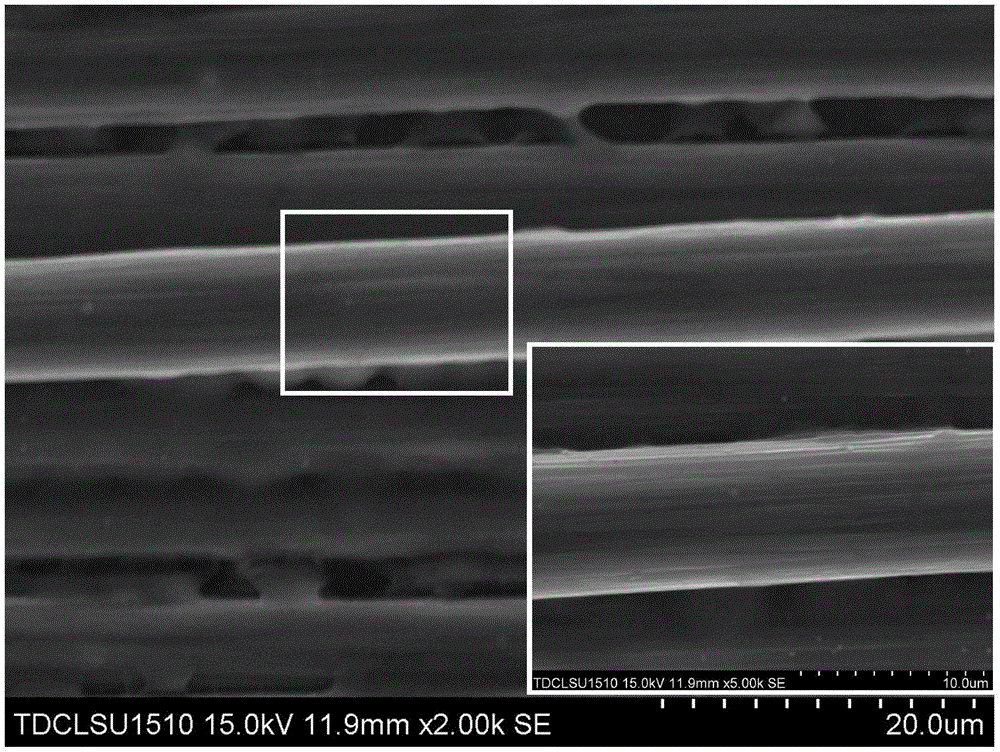

[0021] (3) Preparation of PVDF-coated carbon fiber fabric: immerse the three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com