Method for producing fuel ethanol from household garbage

A technology for fuel ethanol and domestic waste, applied in the direction of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve problems such as poor batch stability, complex components, and unfavorable production of fuel ethanol, so as to improve efficiency and increase Conversion rate, the effect of increasing the value of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

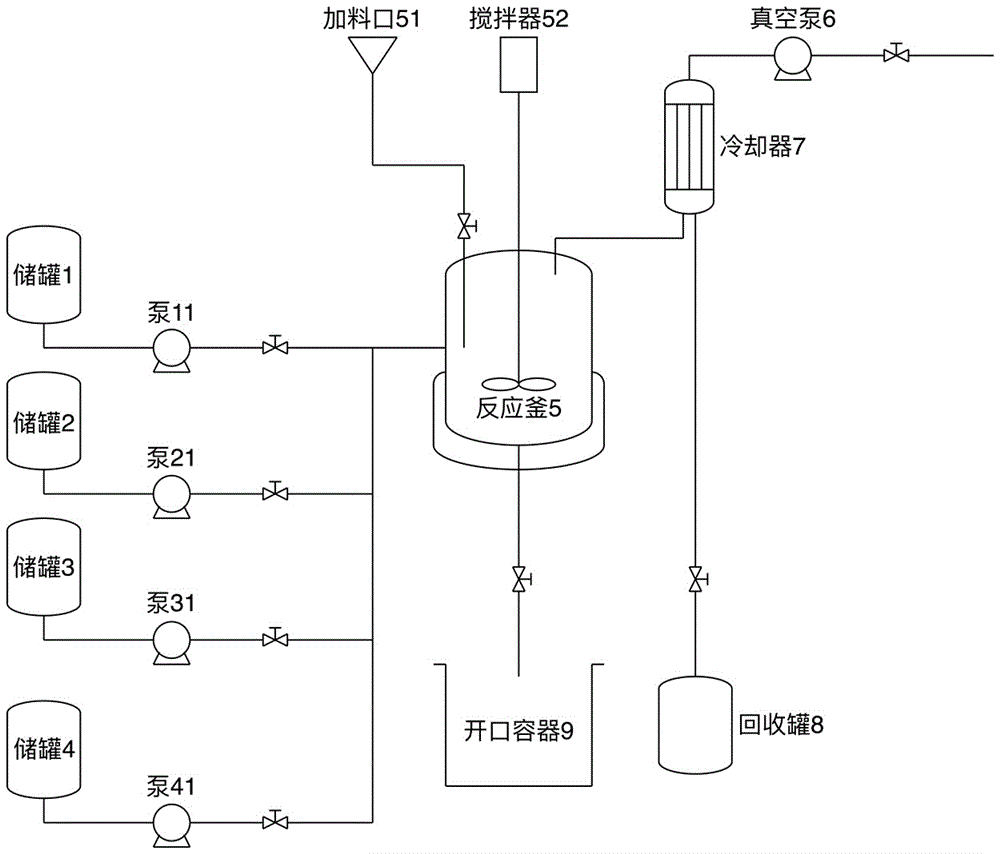

Image

Examples

Embodiment 1

[0063] Step 1: Inactivation treatment

[0064] The fibrous garbage after household waste classification is inactivated by high-temperature steam. During the high-temperature steam treatment, the steam temperature is 120°C and the treatment time is 10 minutes to ensure that the eggs and microorganisms are inactivated; during the inactivation process, at the same time Add acid for treatment to effectively degrade cellulose macromolecules and improve the efficiency of post-hydrolysis. The acid is formic acid; the concentration of the acid is controlled at 1.0%. 10% of the dry weight of fibrous waste;

[0065] Step 2 Preprocessing

[0066] Step 2.1 Collect

[0067] Collect the fibrous waste after the high-temperature steam inactivation treatment in step 1, as the raw material for the next step hydrolysis reaction;

[0068] Step 2.2 Preprocessing the first step

[0069] Add EDTA solution to the fibrous garbage after high-temperature steam inactivation treatment, the concentrati...

Embodiment 2

[0084] Step 1: Inactivation treatment

[0085] The fibrous garbage after the domestic waste classification is inactivated by high-temperature steam. The steam temperature during the high-temperature steam treatment process is 125°C, and the treatment time is 120 minutes to ensure that the eggs and microorganisms are inactivated; during the inactivation process, at the same time Add acid for treatment to effectively degrade cellulose macromolecules and improve the efficiency of post-hydrolysis. The acid is sulfuric acid; the concentration of the acid is controlled at 10%. 0.1% of the dry weight of garbage.

[0086] Step 2 Preprocessing

[0087] Step 2.1 Collect

[0088] Collect the fibrous waste after the high-temperature steam inactivation treatment in step 1, as the raw material for the next step hydrolysis reaction;

[0089] Step 2.2 Preprocessing the first step

[0090] Add EDTA solution to the fibrous garbage after high-temperature steam inactivation treatment, the con...

Embodiment 3

[0105] Step 1: Inactivation treatment

[0106] The fibrous garbage after household waste classification is inactivated by high-temperature steam. During the high-temperature steam treatment, the steam temperature is 130°C and the treatment time is 10 minutes to ensure the inactivation of insect eggs and microorganisms; during the inactivation process, at the same time Adding acid for treatment can effectively degrade cellulose macromolecules and improve the efficiency of hydrolysis in the later stage. The acid is hydrochloric acid; the concentration of the acid is controlled at 5.0%. 1.0% of the dry weight of garbage.

[0107] Step 2 Preprocessing

[0108] Step 2.1 Collect

[0109] Collect the fibrous waste after the high-temperature steam inactivation treatment in step 1, as the raw material for the next step hydrolysis reaction;

[0110] Step 2.2 Preprocessing the first step

[0111] Add EDTA solution to the fibrous garbage after high-temperature steam inactivation treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com