Method for optimizing growth of silicon carbide single crystals

A silicon carbide single crystal and crystal growth technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of increasing crystal graphitization and forming other polytypes, dislocations and micro-pipes, and reducing crystal growth rate. , crystal growth rate limitation and other issues, to achieve the effect of promoting stable growth, inhibiting graphitization, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

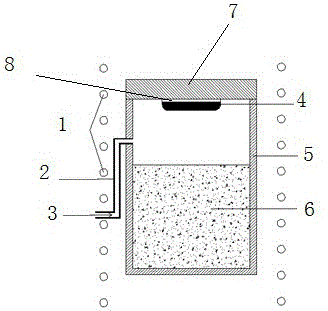

[0023] Example 1: A 4H-SiC single crystal was grown using an induction heating type PVT method single crystal furnace. The specific steps are as follows: (1) Drill a pore with a diameter of 6mm on the upper part of the side wall of the graphite crucible;

[0024] (2) Put the SiC raw material on the bottom of the graphite crucible, place the SiC seed crystal with a diameter of 4 inches on the graphite tray connected to the upper cover of the graphite crucible, the growth surface is the carbon surface, and the growth direction is the axial direction;

[0025] (3) Place the assembled crucible in the growth chamber of the single crystal furnace, one end of the graphite conduit is connected to the air hole on the side wall of the graphite crucible, and the other end is connected to the silane pipeline of the induction heating furnace;

[0026] (4) Vacuumize the graphite crucible before the silicon carbide crystal grows, so that the vacuum degree in the growth chamber reaches 1×10 -...

Embodiment 2

[0030] Example 2: A 6H-SiC single crystal was grown using an induction heating type PVT method single crystal furnace, and the specific steps were as follows: (1) Drilling a pore with a diameter of 6 mm on the upper part of the side wall of the graphite crucible;

[0031] (2) Put the SiC raw material on the bottom of the graphite crucible, place the SiC seed crystal with a diameter of 4 inches on the graphite tray connected to the upper cover of the graphite crucible, the growth surface is the carbon surface, and the growth direction is the axial direction;

[0032] (3) Place the assembled crucible in the growth chamber of the single crystal furnace, one end of the graphite conduit is connected to the air hole on the side wall of the graphite crucible, and the other end is connected to the silane pipeline of the induction heating furnace;

[0033] (4) Vacuumize the graphite crucible before the silicon carbide crystal grows, so that the vacuum degree in the growth chamber reache...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com