Large bottom water sandstone oil reservoir development physical simulation experiment device and working method thereof

A sandstone reservoir, physical simulation technology, applied in the direction of production fluid, earthwork drilling, measurement, etc., can solve the problems of limited reuse times, difficulty in forming oil and water layers, and no thickness dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

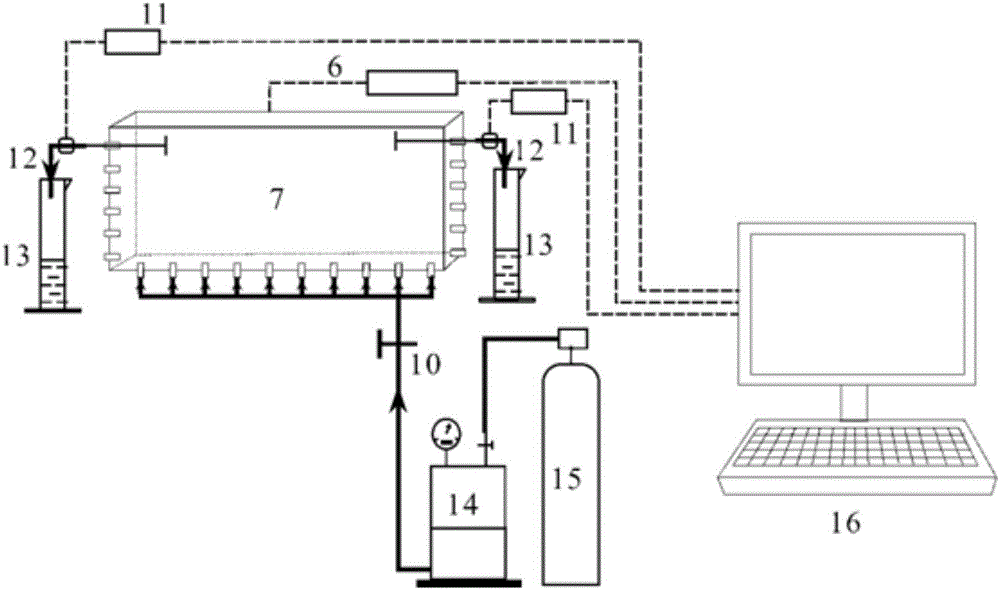

[0050] When this physical model is used for bottom water energy extraction experiments, the experimental steps are as follows:

[0051] Such as figure 2 As shown, in this embodiment, the bottom water injection hole of the body is sequentially connected to the on-off valve 10 , the water storage tank 14 and the gas cylinder 15 through the pipe body.

[0052] The main body of the model 7 uses sand to fill the oil-water layer. The specific method: screen sand with a certain mesh number to wash it with water to remove dust; place the model vertically, and calculate the thickness of the water layer and oil layer according to the thickness ratio of the oil-water layer; Add water repeatedly to the thickness of the water layer, and shake the model during the process of adding sand and water; calculate the pore volume of the water layer; according to the actual formation bound water saturation and water layer porosity as parameters, dry sand is mixed with a certain amount of water and...

Embodiment 2

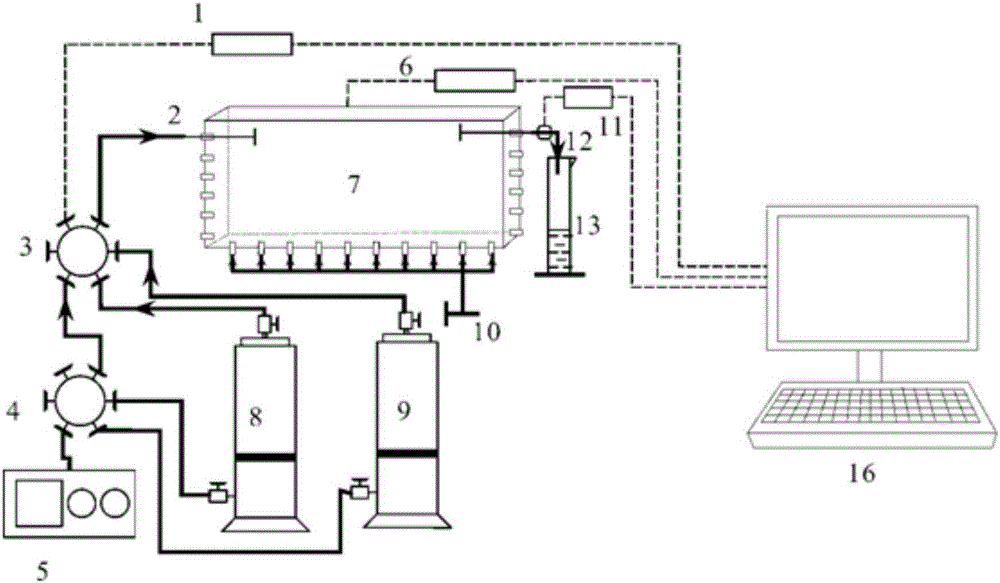

[0058] When this physical model is used for waterflooding experiments in closed bottom water reservoirs, the experimental steps are as follows:

[0059] Such as image 3 As shown, in this embodiment, the natural energy in Embodiment 1 is exploited first until the water content reaches a certain degree, then the bottom water energy switch valve 10 is closed, the left production well is connected to the injection system, and the pressure sensor 1 is monitored at the same time The resulting injection pressure.

[0060] The production well on the right is connected to the pressure control device 11 through the constant pressure control system, that is, the development well 12, to control the production fluid velocity and monitor the wellhead pressure at the same time.

[0061] The production liquid enters the metering device 13 after passing through the constant pressure control system, and accurately measures the liquid production volume.

[0062] The saturation monitoring syst...

Embodiment 3

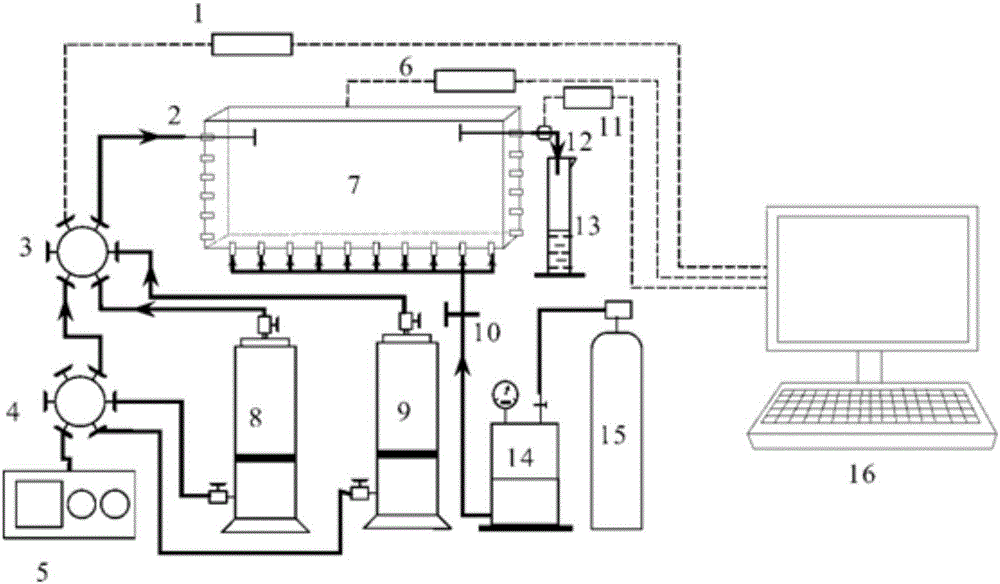

[0065] When this physical model is used for the unbalanced waterflooding experiment of externally connected bottom water reservoirs, the experimental steps are as follows:

[0066] Such as figure 1 As shown, in this embodiment, the natural energy in Embodiment 1 is exploited first until the water content reaches a certain temperature, and then the injection system is connected to carry out water injection exploitation.

[0067] Calculate the injection-production ratio according to the actual reservoir, control the injection volume and production volume to reach the actual injection-production ratio, and pay attention to the sufficient liquid volume in the water storage tank 14 container in the bottom water system.

[0068] The production well on the right is connected to the pressure control device 11 through the constant pressure control system, that is, the development well 12, to control the production fluid velocity and monitor the wellhead pressure at the same time.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com