PE (Poly Ethylene) ball valve with sewage discharge function

A ball valve and functional technology, applied in the field of PE ball valves, can solve the problems of blocked opening and closing of ball valves, inability to open and close, and loose closing, etc., to achieve flexible opening and closing, restore self-cleaning, and improve pressure bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

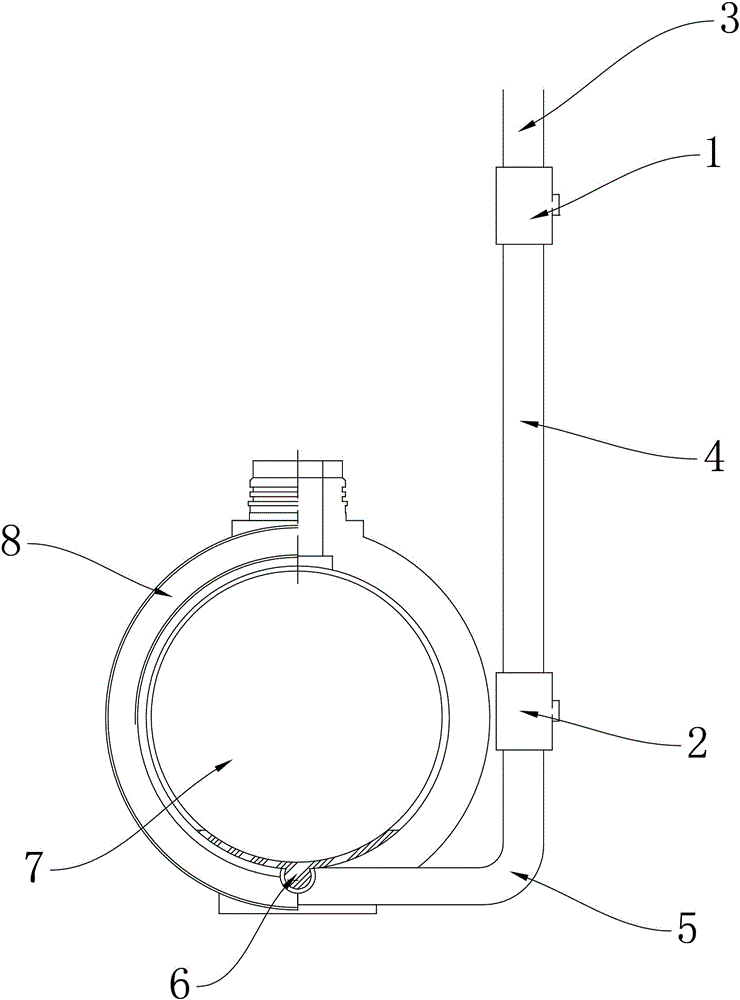

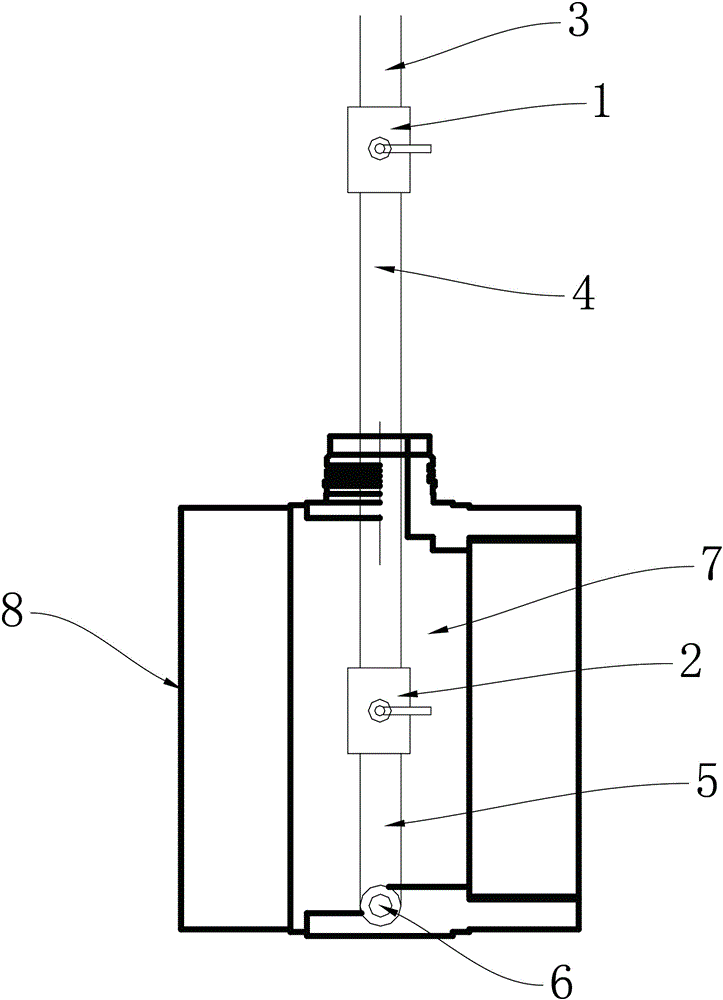

[0012] See Figure 1 to Figure 2 , a PE ball valve with sewage discharge function, including a valve body 8 and a ball valve 7 arranged in the valve body 8, a sediment sedimentation device 6 is arranged between the bottom of the valve body 8 and the bottom of the ball valve 7, and the sediment sedimentation device 6 Connected with the first pipeline 5 leading into the valve body 8, the first pipeline 5 extends out of the valve body 8 and is connected with the first ball valve 2, the first ball valve 2 is connected to the water storage pipe 4, and the water storage pipe 4 is also Connected to the second ball valve 1; the second ball valve 1 is provided with a second pipeline 3 for filling water and removing sediment water; the second pipeline 3 is a rubber hose; the first pipeline 5 is hot-melted by a socket It is composed of a welded short pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com