A method and system for recovering and utilizing exhaust heat energy of a fully automatic deaerator

A technology of heat energy recovery and deaerator, which is applied in chemical instruments and methods, separation methods, preheating, etc., can solve the problems of difficulty in exhaust gas recovery and utilization, no additional pressure is allowed, and low efficiency of heat energy recovery. Complete steam, stable liquid level and high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

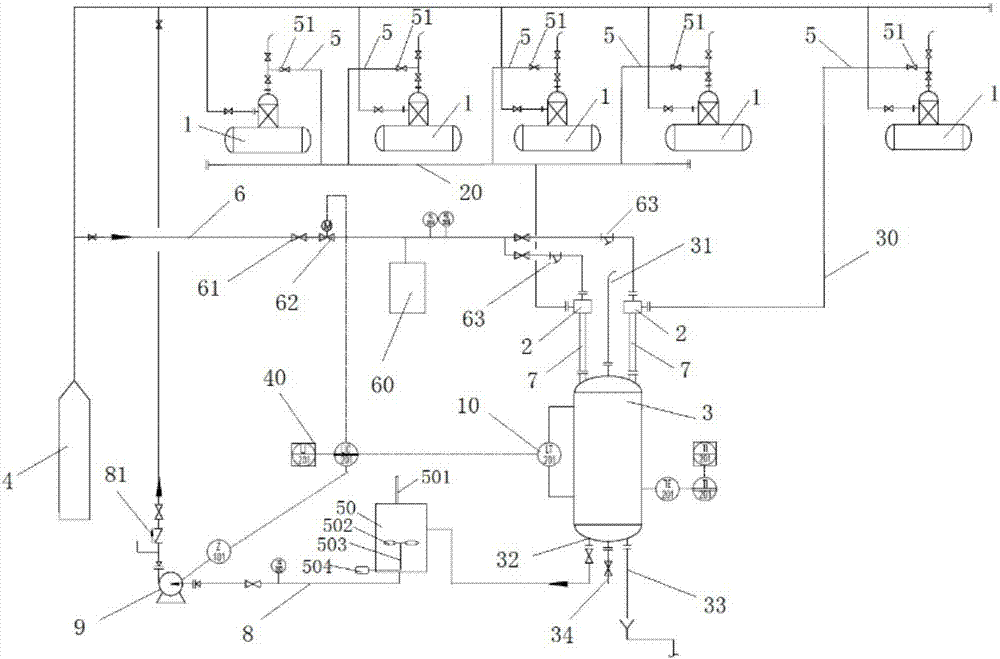

[0042] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the specific implementation modes of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0043] Please refer to figure 1 , the embodiment of the present invention provides a kind of automatic deaerator exhaust steam heat recovery method, comprising the following steps:

[0044] (1) Prepare a fully automatic deaerator exhaust steam heat recovery system, including several deaerators 1, several water vapor mixers 2, degassing water storage tank 3, pressure buffer tank 50, slag cooling machine 4 and DCS control System 40, wherein, the deaerator 1 is connected to the water vapor mixer 2 through a steam discharge pipe 5, and the steam discharge pipe 5 communicates with the side air inlet on the side wall of the water vapor mixer 2, and the steam discharge A steam valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com