Transcritical CO2 compound heat pump and control method thereof

A CO2, transcritical technology, applied in the field of heat pumps, can solve the problems of energy waste, outlet temperature of controlled gas coolers, complicated water distribution and connection, etc., to achieve a wide range of applications, high energy utilization, excellent flow and heat transfer characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

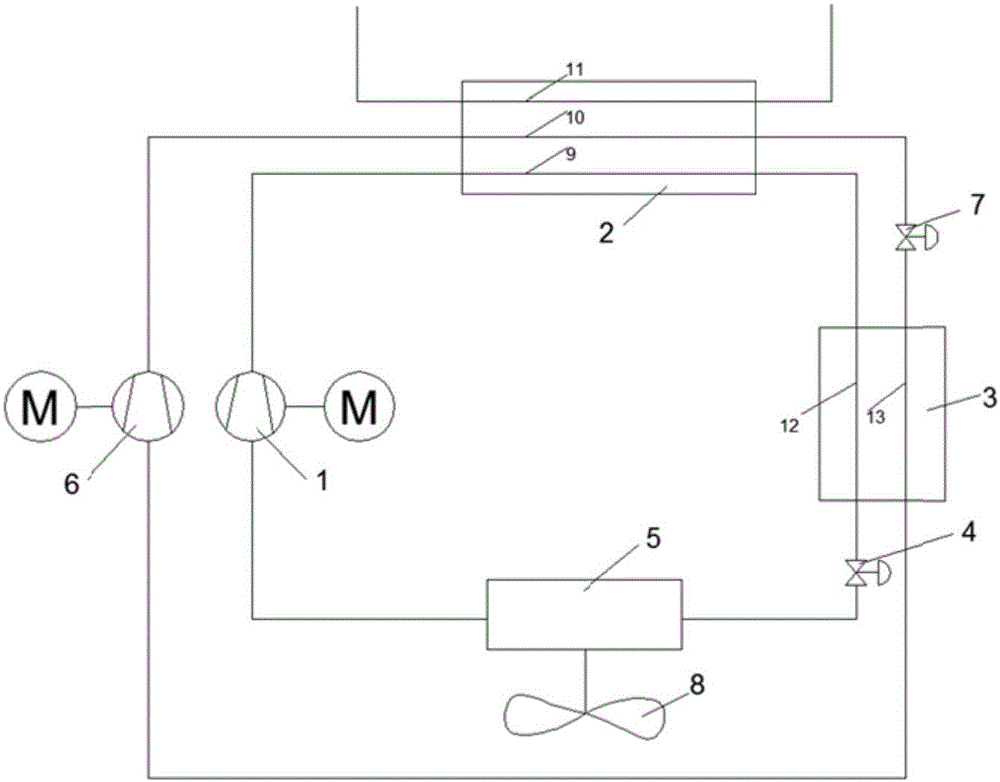

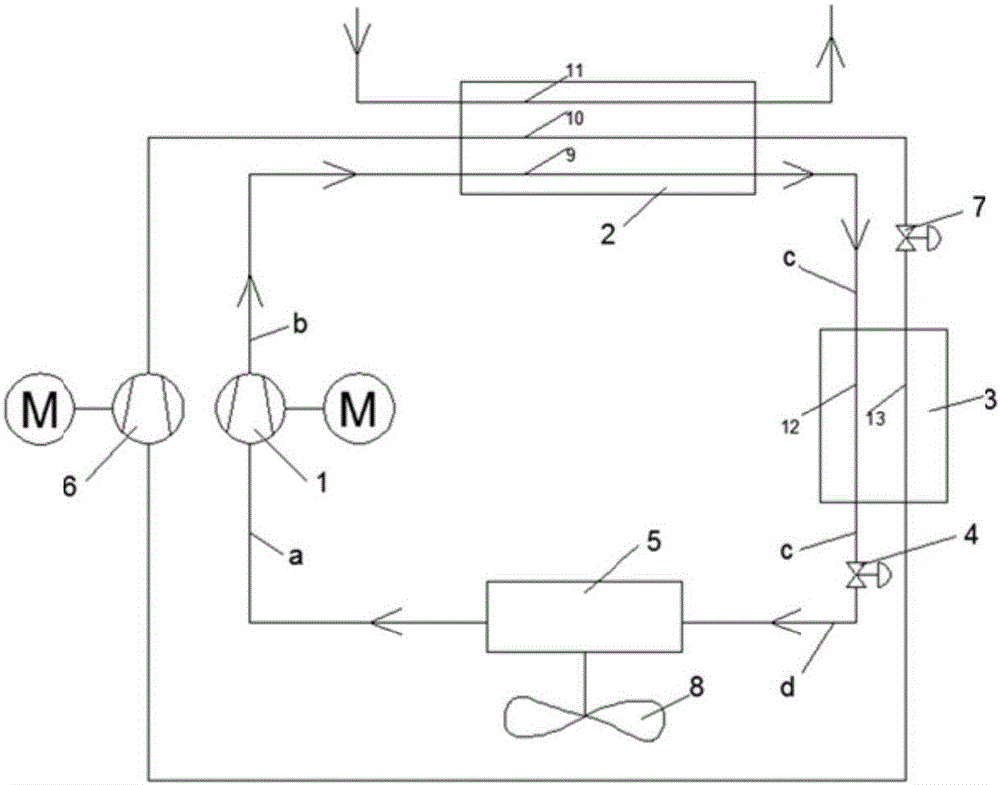

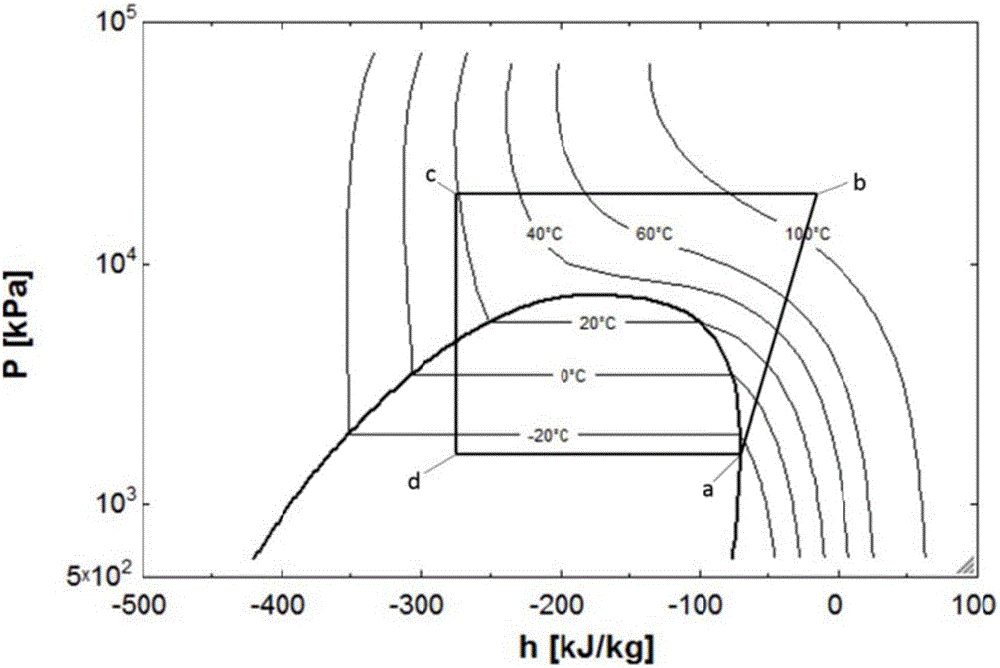

[0039] see figure 1 , the present invention is a transcritical CO 2 Compound heat pumps, including CO 2 Main road compressor 1, including CO 2 Main Road 9, CO 2 The air-cooled-air-cooled composite device 2 of the three passages of the auxiliary road 10 and the water road 11, including CO 2 Main road over cold section 12 and CO 2 Subcooling-evaporation compounder 3, evaporator 5, CO 2 Auxiliary compressor 6;

[0040] The present invention is a kind of transcritical CO 2 The composite heat pump includes two circuits, the main circuit and the auxiliary circuit;

[0041] Main circuit: CO 2 The outlet of the main road compressor 1 is connected to the CO of the air-cooled-air-cooled composite unit 2 2 The inlet of the main road 9, the CO of the air-cooled-air-cooled composite 2 The outlet of the main road 9 is connected to the CO 2 The inlet of subcooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com