A dynamic headspace liquid phase microextraction method based on extraction solvent volatilization

A technology for extracting solvent and headspace liquid, which is applied in the field of dynamic headspace liquid phase microextraction based on extraction solvent volatilization, can solve the problems of easy volatilization, achieve the effects of stable liquid droplets, small detection interference, and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

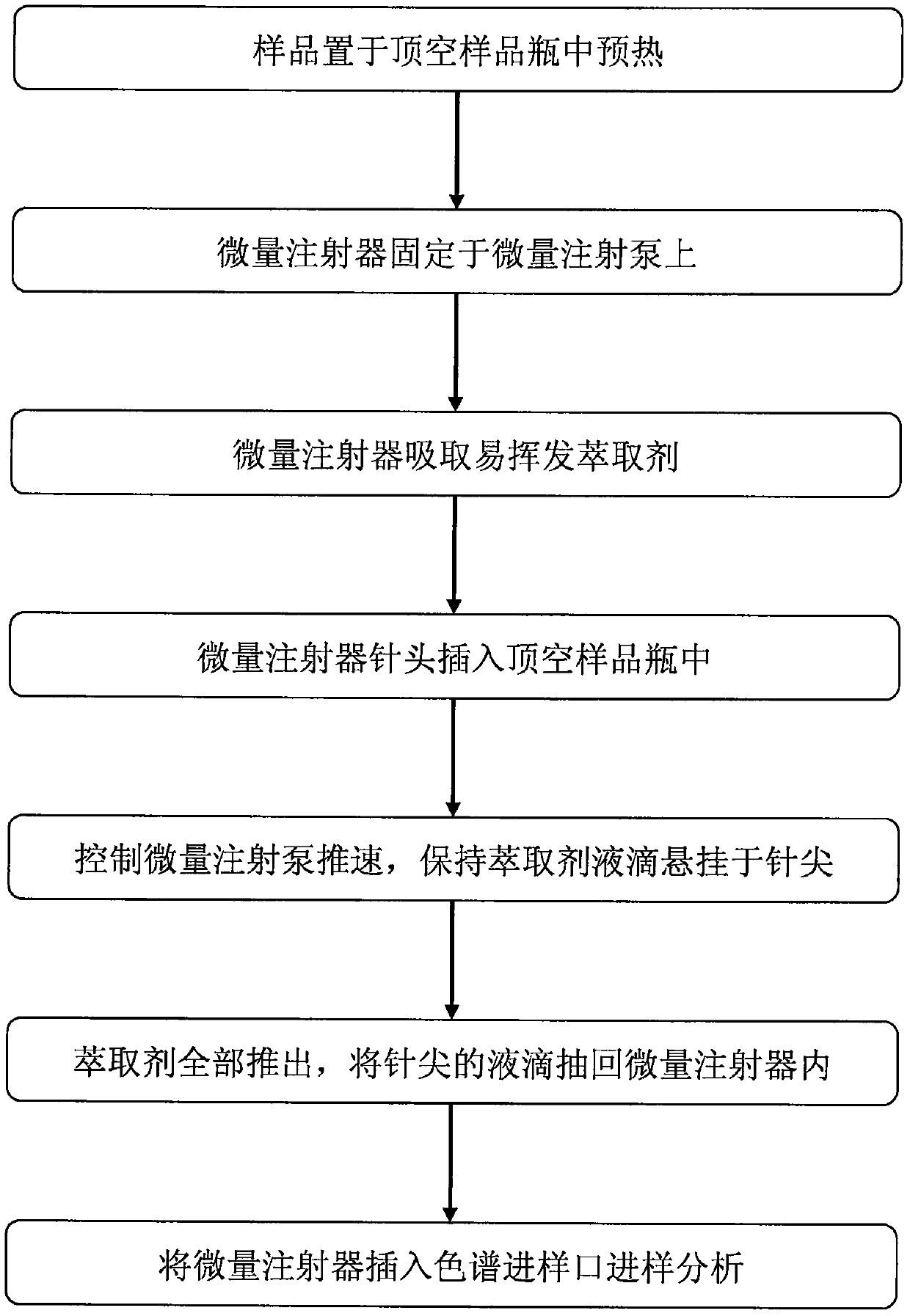

[0020] Such as figure 1 As shown, in step 1, the sample is placed in a headspace vial and preheated to equilibrium at an extraction temperature between room temperature and 100°C; in step 2, the microsyringe is fixed on the microsyringe pump; in step 3, Use a microsyringe to draw 10-100 microliters of extraction solvent that is volatile at the extraction temperature; step 4, insert the microsyringe needle into the headspace vial with the needle tip in the gas phase above the sample; step 5, use a microsyringe pump Push the micro-injector at a speed of 0.5-10 μl / min. The pushing speed is balanced with the volatilization speed of the extraction solvent, so that the droplet formed by the extraction solvent at the tip of the needle is always kept at a stable level, neither due to excessive droplet size And falling off from the needle tip does not cause the droplet to disappear due to too fast volatilization of the solvent; Step 6, when the extraction solvent in the syringe is perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com