Method for increasing specific capacity of MnO2-based supercapacitor simply and quickly

A supercapacitor, specific capacity technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of reduced active material performance, slow radius migration, low specific capacity, etc., to improve performance and low cost. , the effect of increasing the specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

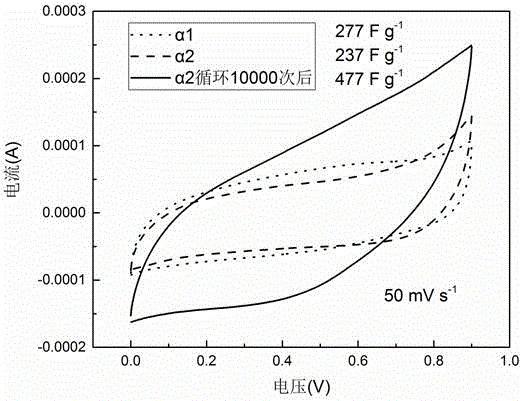

[0043] α-MnO 2 Base electrode:

[0044] (1) Preparation of α-MnO by hydrothermal method 2 Powder: weigh MnSO 4 Mass 1.352 g was dissolved in 60 mL of water, weighed KMnO 4 Dissolve the mass of 1.264 g in 60 mL of water, then mix the above two solutions at a volume ratio of 1:1, stir for 20 min to obtain a suspension, transfer it to a reaction kettle, seal it, react at 160°C for 24 h, pour water and cool to room temperature , filtered, washed, and dried at 80°C for 8 h to obtain α-MnO 2 powder;

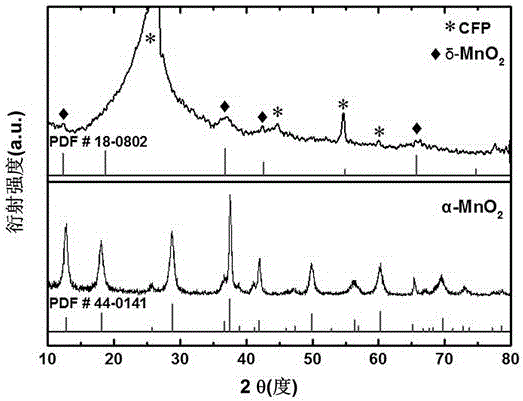

[0045] The resulting α-MnO 2 The XRD pattern of the powder is as follows figure 1 shown by figure 1 It can be seen that the α-MnO prepared by hydrothermal method 2 α-MnO powder and standard PDF card2 consistent;

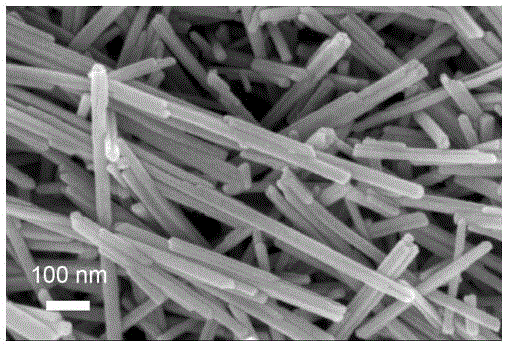

[0046] The resulting α-MnO 2 The SEM picture of the powder is as follows figure 2 shown by figure 2 It can be seen that the obtained α-MnO 2 The powder is in the shape of nano needles.

[0047] (2) Prepare slurry: weigh α-MnO 2 Powder (8 mg), acetylene black ...

Embodiment 2

[0054] α-MnO 2 Base electrode:

[0055] (1) Preparation of α-MnO by hydrothermal method 2 Powder: weigh MnSO 4 Quality 1.352g was dissolved in 40 mL water, weighed KMnO 4 The mass of 1.264g was dissolved in 40 mL of water, and then the above two solutions were mixed at a volume ratio of 1:1, and stirred for 40 minutes to obtain a suspension, which was transferred to a reaction kettle, sealed, and reacted at 180°C for 18 hours, then poured water and cooled to At room temperature, filter, wash, and dry at 80°C for 8 h to obtain α-MnO 2 powder;

[0056] The resulting α-MnO 2 The XRD figure and the SEM figure of powder are similar to embodiment 1;

[0057] (2) Prepare slurry: weigh α-MnO 2 Powder (6 mg), acetylene black (3 mg) and PTFE (1 mg), mixed with ethanol to dissolve, ultrasonically dispersed for 30 min to obtain a slurry;

[0058] (3) Determine the quality: cut a piece of copper foil as a carrier, and coat the slurry with 2 g / m 2 , using the difference method to c...

Embodiment 3

[0064] α-MnO 2 Base electrode:

[0065] (1) Preparation of α-MnO by hydrothermal method 2 Powder: weigh MnSO 4 Quality 1.352g was dissolved in 20 mL of water, weighed KMnO 4 The mass of 1.264g was dissolved in 20 mL of water, and then the above two solutions were mixed at a volume ratio of 1:1, and stirred for 50 min to obtain a suspension, which was transferred to a reaction kettle, sealed, and reacted at 120°C for 32 h, poured with water and cooled to At room temperature, filter, wash, and dry at 80°C for 8 h to obtain α-MnO 2 powder;

[0066] The resulting α-MnO 2 The XRD figure and the SEM figure of powder are similar to embodiment 1;

[0067] (2) Prepare slurry: weigh α-MnO 2 Powder (7 mg), acetylene black (2 mg) and PTFE (1 mg), mixed with ethanol to dissolve, ultrasonically dispersed for 60 min to obtain a slurry;

[0068] (3) Determine the quality: cut a piece of copper foil as a carrier, and coat the slurry at 5g / m 2 , using the difference method to calculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com