Dual-lithium-salt compounded PEO-based polymer electrolyte and preparation method therefor

An electrolyte and polymer technology, applied in the field of preparation of polyethylene oxide (hereinafter referred to as PEO)-based polymer electrolyte, can solve the problems of low conductivity, poor interface stability, low battery cycle life, etc., achieve high conductivity, reduce Effect of increasing crystallinity and interfacial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In an argon atmosphere glove box, weigh 0.3g~0.6g of PEO with a molecular weight of 2,000,000~4,000,000, put it into a 20mL mixing bottle, then add 10mL~15mL of acetonitrile, and stir magnetically until the PEO is completely dissolved without obvious solid particles exist, then add 0.08g~0.16g LiTFSI, stir until completely dispersed, add 0.02~0.04g nano-alumina, particle size 20nm~100nm, after the dispersion is complete, then weigh 0.02g LiI powder into it, and then use a magnetic stirring device to mix uniform. After stirring for 48 hours, it becomes a milky white suspension. Pour it into a polytetrafluoroethylene mold and cast it to form a film. Let it dry naturally. After 72 hours, it is completely dry and becomes an opaque film. Carefully tear it off with tweezers and punch it into circles. Tablets are ready for use.

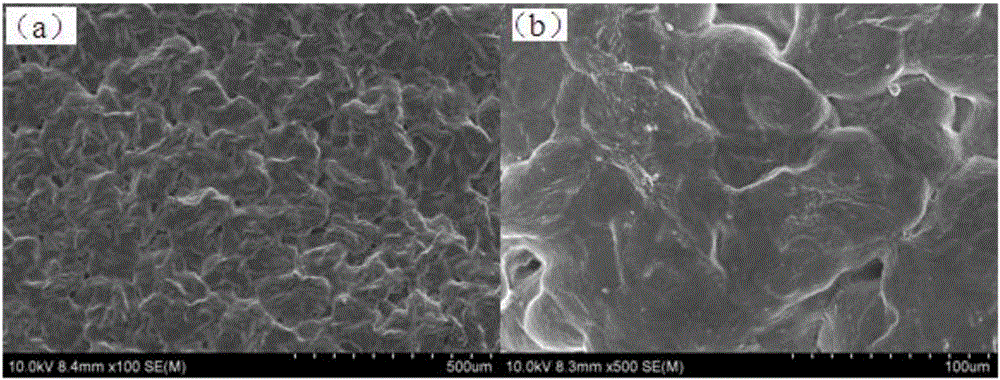

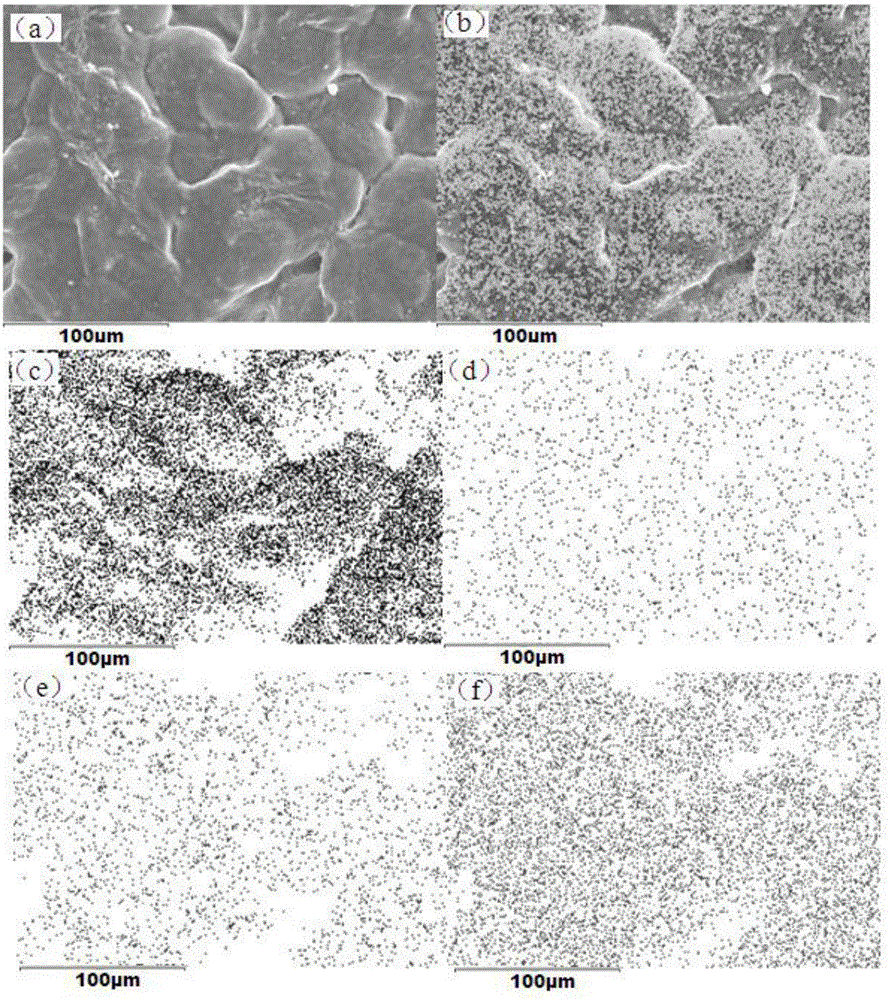

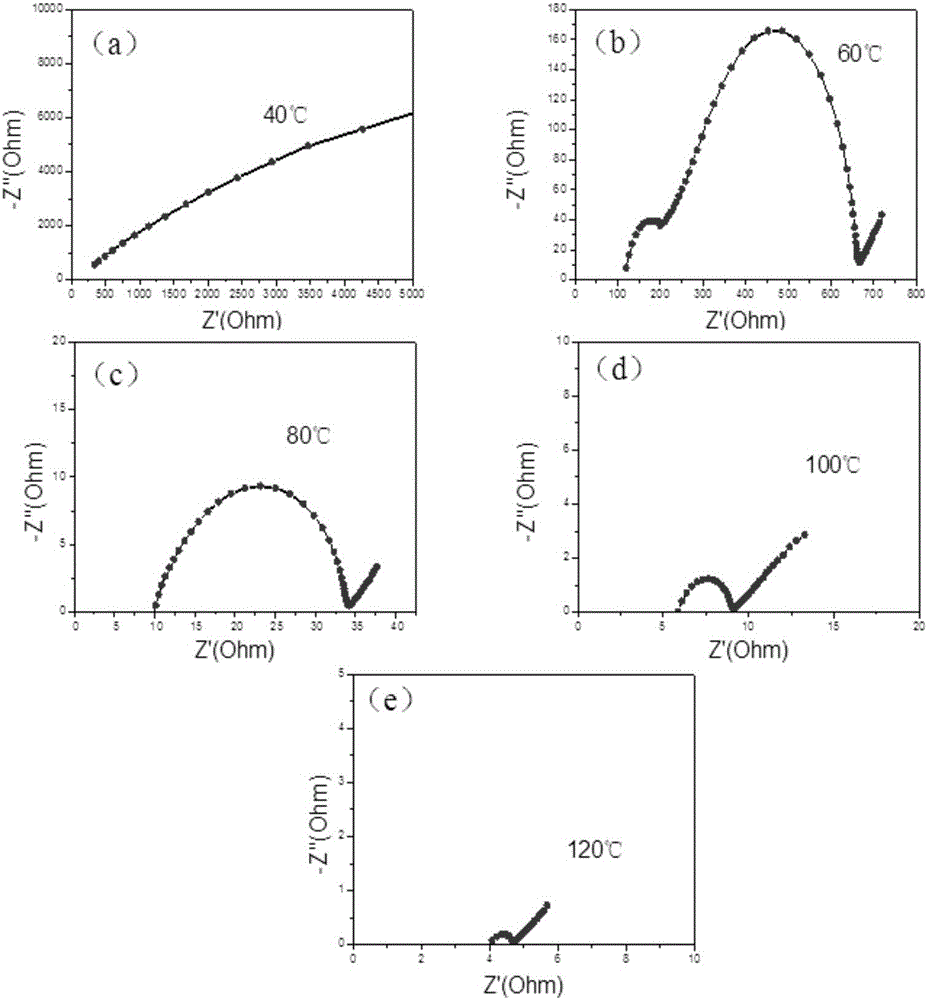

[0030] The scanning electron microscope (SEM) picture of the PEO-based polymer electrolyte film obtained by this embodiment is as follows figure 1 ...

Embodiment 2

[0036] In an argon atmosphere glove box, weigh 0.3g~0.6gPEO, molecular weight 4000000~5000000, put it into a 20mL mixing bottle, then add 10mL~15mL acetonitrile, stir magnetically until the PEO is completely dissolved, no obvious solid particles exist, Then add 0.08g~0.16g LiTFSI, stir until completely dispersed, add 0.02~0.04g nano-alumina, particle size 20nm~30nm, after the dispersion is complete, weigh 0.04g LiI powder into it, and then use a magnetic stirring device to mix evenly. After stirring for 48 hours, it becomes a milky white suspension. Pour it into a polytetrafluoroethylene mold and cast it to form a film. Let it dry naturally. After 72 hours, it is completely dry and becomes an opaque film. Carefully tear it off with tweezers and punch it into circles. Tablets are ready for use.

[0037] The PEO-based polymer electrolyte film obtained in this example was tested in the same way as in Example 1, and the test results were equivalent.

[0038]In the PEO-based polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com