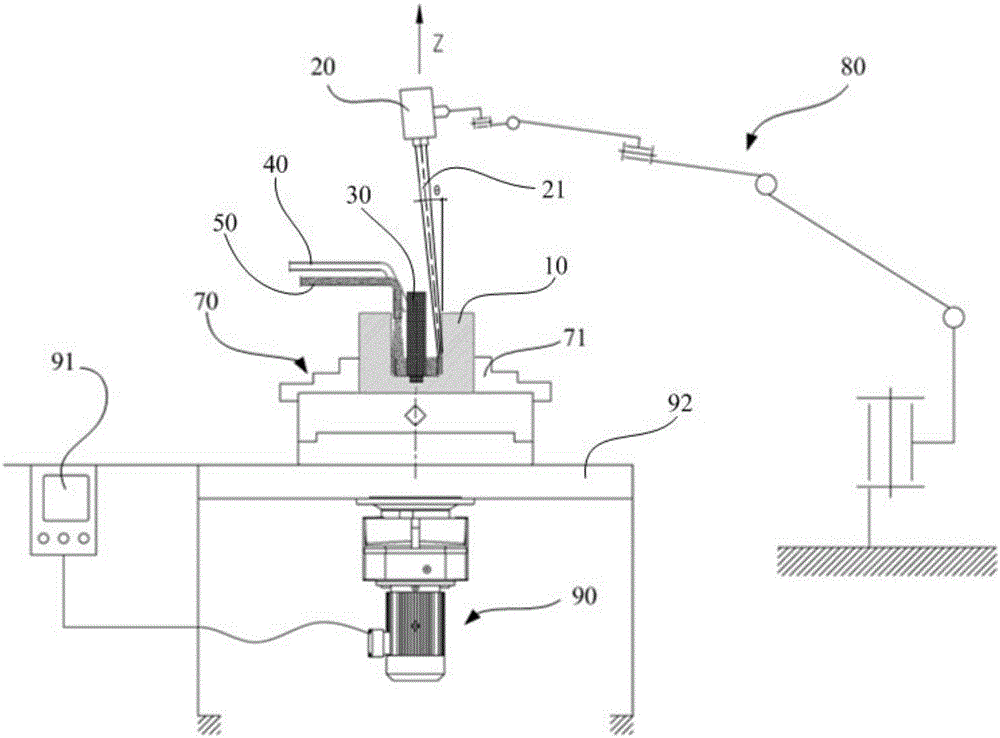

Surface modification method and device for modifying surface of inner wall of hole by utilizing laser overlaying welding

A surface modification, laser beam technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of limited welding torch size and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

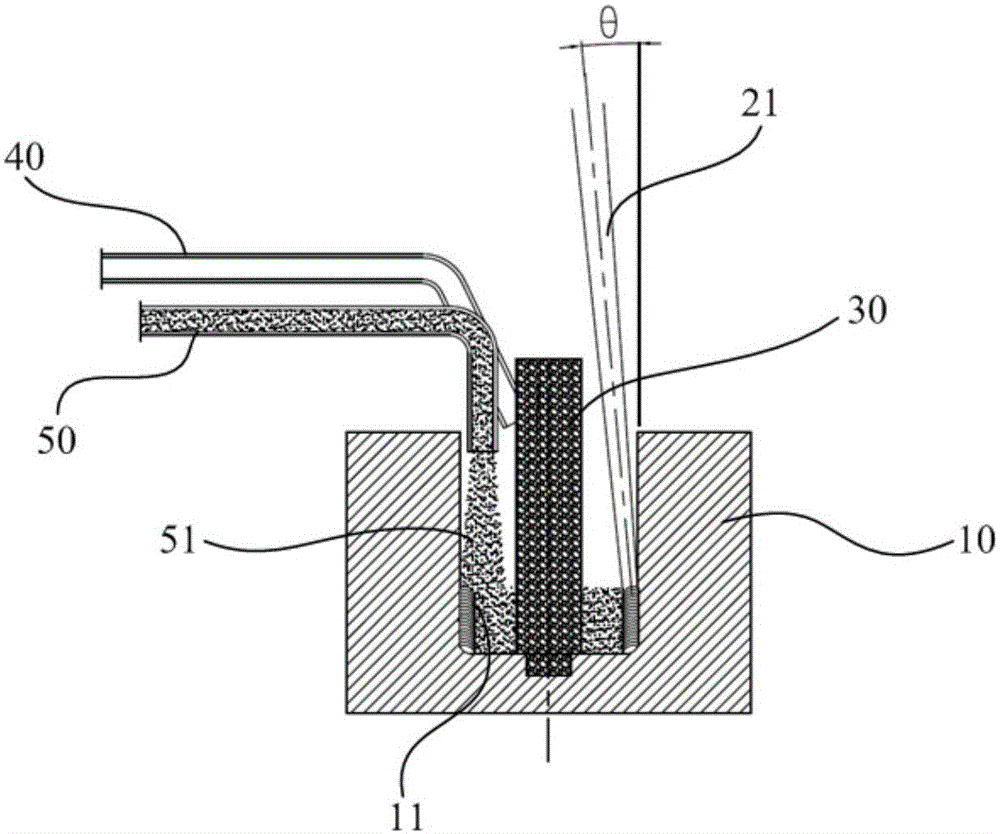

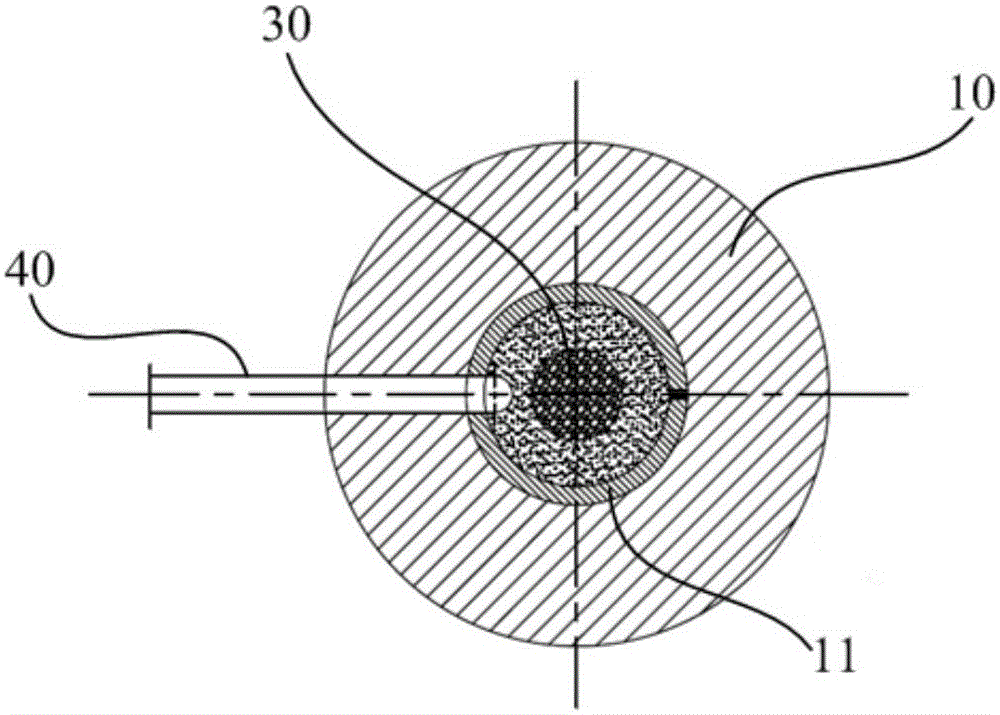

[0082] The blind hole in the workpiece 10 has a diameter of 35mm and a depth of 420mm, and the step of surface modification of the inner wall of the blind hole includes:

[0083] A counterbore is provided on the bottom surface 10b of the blind hole of the workpiece 10 for fixing the spacer 30;

[0084] The workpiece 10 is clamped on the three-jaw chuck 71, and then the isolation part 30 is installed on the counterbore, and the isolation part 30 is a cylinder made of copper with a diameter of 15 mm;

[0085] Adjust the orientation of the laser 20 so that the laser beam 21 can be obliquely irradiated on the surface of the inner wall 10a of the blind hole through the opening of the blind hole of the workpiece 10, and the inclination angle θ is 8°; and adjust the initial position of the laser 20 so that the laser beam 21 The initial position of the light spot on the surface of the inner wall 10a is at the edge of the bottom surface 10b; wherein, the beam diameter of the laser beam...

application example 2

[0090] The blind hole in the workpiece 10 has a diameter of 20mm and a depth of 180mm, and the step of surface modification of the inner wall of the blind hole includes:

[0091] A counterbore is provided on the bottom surface 10b of the blind hole of the workpiece 10 for fixing the spacer 30;

[0092] The workpiece 10 is clamped on the three-jaw chuck 71, and then the isolation part 30 is installed on the counterbore. The isolation part 30 is a cylinder made of alumina ceramics with a diameter of 7 mm;

[0093] Adjust the orientation of the laser 20 so that the laser beam 21 can be obliquely irradiated on the surface of the inner wall 10a of the blind hole through the opening of the blind hole of the workpiece 10, and the inclination angle θ is 3°; and adjust the initial position of the laser 20 so that the laser beam 21 The initial position of the light spot on the surface of the inner wall 10a is at the edge of the bottom surface 10b; wherein, the beam diameter of the laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com