Microfluidic chip used for transmissive terahertz time-domain spectroscopy system and manufacturing method thereof

A terahertz time domain, microfluidic chip technology, applied in the field of terahertz time domain spectroscopy, can solve the problems of incomplete microchannel replication, low production efficiency of hot pressing method, unstable chip quality, etc. The effect of excessive rate, certain mechanical strength, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

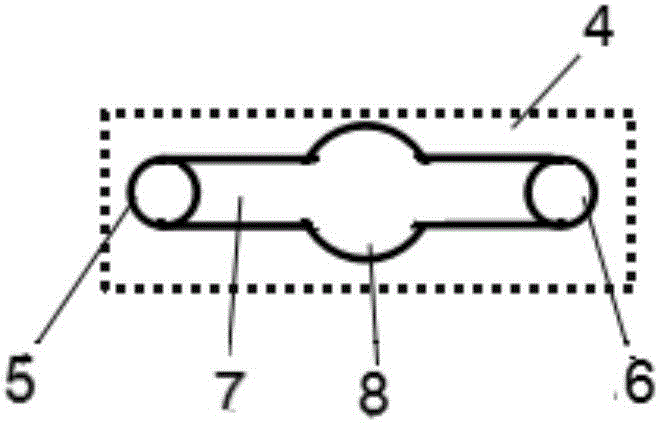

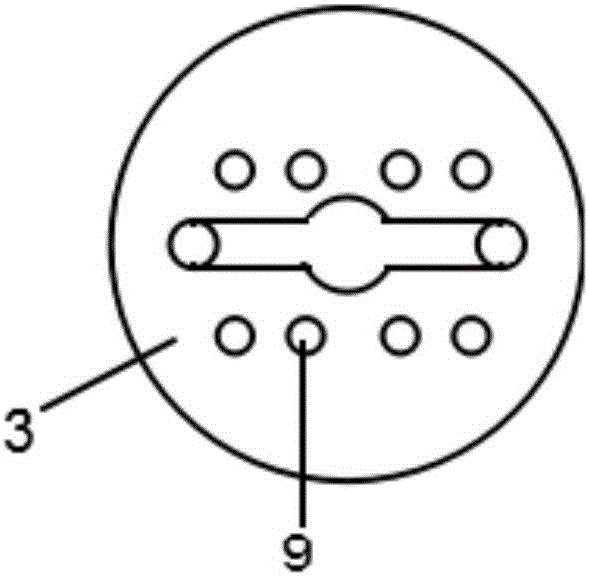

[0030] like Figure 5 As shown, the present invention provides a microfluidic chip suitable for a transmission terahertz time-domain spectroscopy system.

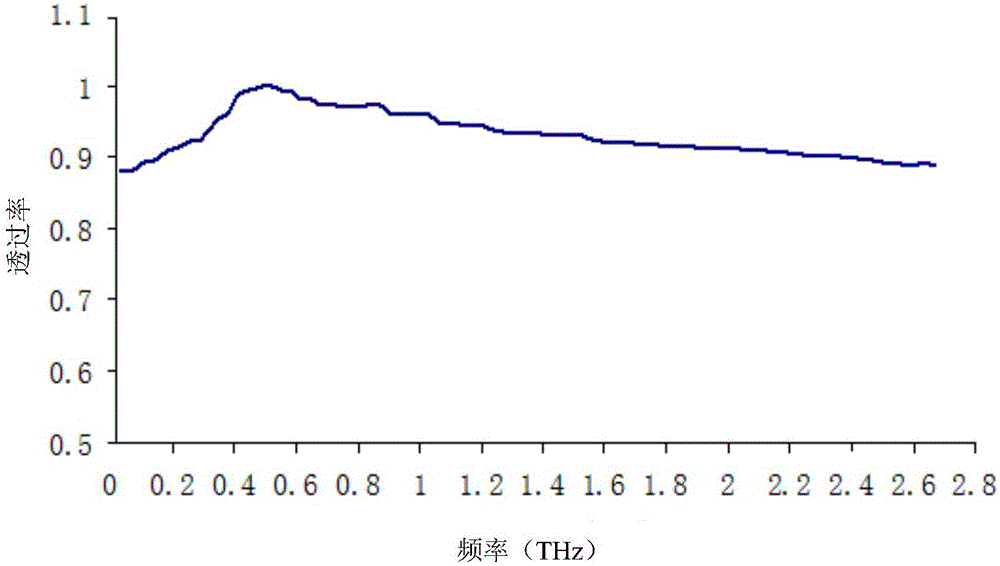

[0031] In this embodiment, APS 8009TC is selected as the material of the substrate 1 and the cover sheet 2. APS 8009TC is a material with a very high transmittance in a terahertz microfluidic system and can be used for channel processing. APS 8009TC is a cycloolefin polymer with hydrophobicity, transparency to visible light and high terahertz transmittance. Compared with glass, quartz, plexiglass, polydimethylsiloxane (PDMS) and other materials that are suitable for precision machining of microchannels and have been widely used in the field of microfluidics, APS8009TC has very high permeability in the terahertz range. Overrate, figure 1 It is shown that the transmittance in the range of 0.1-2.7 THz i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com