A kind of polyacrylate resin and preparation method thereof

A technology of polyacrylate and methyl methacrylate, which is applied in the field of polyacrylate resin and its preparation, can solve the problems of inability to guarantee the long-term protection of rubber windshield, fatigue aging of paint, non-flame retardancy, etc., and achieve high cohesion and adhesion Strong, good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

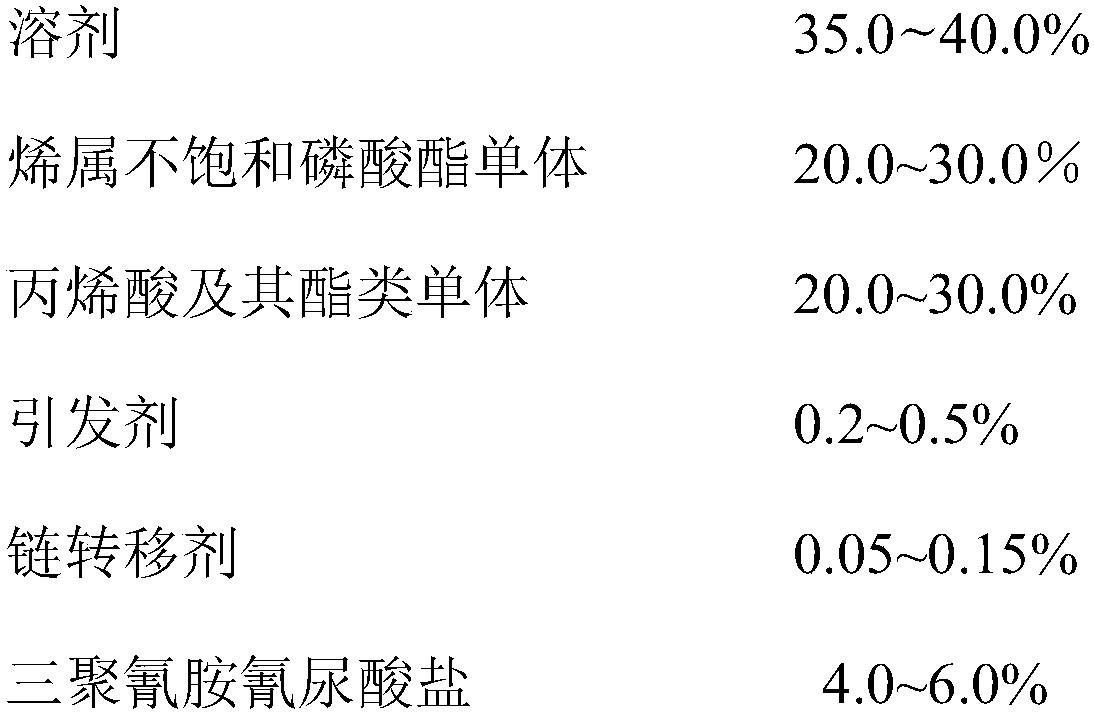

Method used

Image

Examples

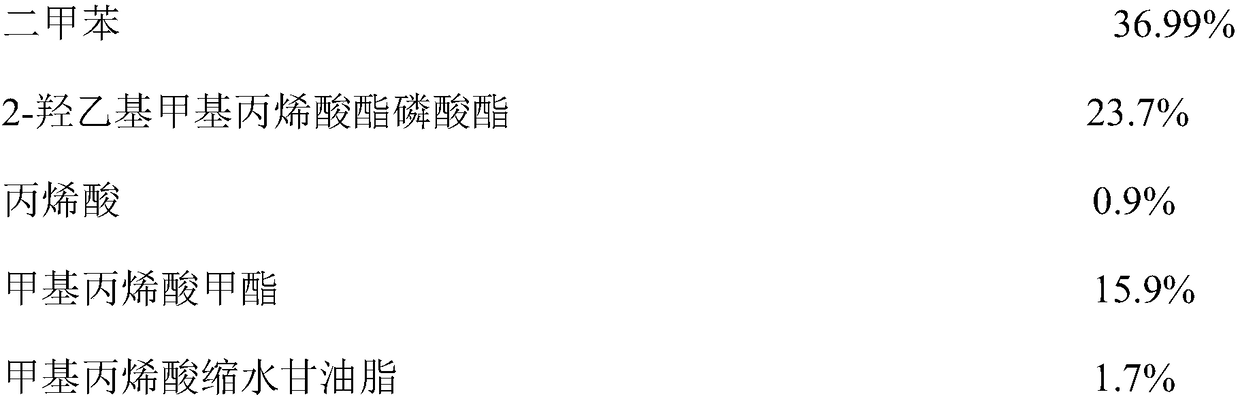

Embodiment 1

[0027] In a four-neck flask equipped with a condenser, a dropping device, a stirrer, and a thermometer, add 270.0 grams of xylene, and raise the temperature to 130-150°C; then start to drop 0.72 grams of di-tert-butyl peroxide, 135.2 grams of hydroxyethyl methacrylate phosphate, 95.3 grams of methyl methacrylate, 5.07 grams of methacrylic acid, 0.55 grams of tert-12 mercaptan, and 30.9 grams of butyl methacrylate monomer mixture, 2.5-3 The hour dropwise addition was completed. The reaction was continued at 150° C. for 1 hour, and a solution of 0.51 g of di-tert-butyl peroxide (dissolved in 12.0 g of xylene) was added. After 1 hour, the temperature was lowered to 60° C., 30 grams of melamine cyanurate was added, filtered, the filter cake was taken, and dried to obtain a highly elastic polyacrylate resin.

Embodiment 2

[0029] Add 276.0 g of xylene to a four-necked flask equipped with a condenser, a dropping device, a stirrer, and a thermometer, and raise the temperature to 130-150°C. Then start to drop 0.90 grams of dicumyl peroxide, 132.0 grams of 2-hydroxyethyl methacrylate phosphate, 75.9 grams of methyl methacrylate, 6.8 grams of acrylic acid, and 0.58 grams of isooctyl 3-mercaptopropionate. , 56.0 grams of butyl acrylate, and 6.0 grams of methacrylic acid-β-hydroxyethyl ester monomer mixture solution, which was added dropwise in 2.5-3 hours. A solution of 0.65 g of dicumyl peroxide (dissolved in 12 g of xylene) was added, and the addition was completed dropwise within 1 hour, and the reaction was continued for 1 hour at 130-150° C. Cool down to 60° C. after 1 hour, add 28 grams of melamine cyanurate, and filter to obtain a highly elastic polyacrylate resin with flame-retardant and self-extinguishing function.

Embodiment 3

[0031] Add 256.0 g of xylene to a four-necked flask equipped with a condenser, a dropping device, a stirrer, and a thermometer, and raise the temperature to 130-150°C. Then began to drop 0.80 grams of dibenzoyl peroxide, 157.0 grams of 2-hydroxyethyl methacrylate phosphate, 60.0 grams of methyl methacrylate, 6.3 grams of methacrylic acid, 70.2 grams of butyl acrylate, dodecyl sulfide 0.63 grams of alcohol, 5.1 grams of isobornyl methacrylate monomer mixture, 2.5 to 3 hours to complete the addition. The reaction was continued at 150°C for 1 hour. Add 0.65 g of tert-butyl hydroperoxide (dissolved in 12 g of xylene) solution, cool down to 60° C. after 1 hour, and add 34 g of melamine cyanurate. After filtering, a highly elastic polyacrylate resin with flame-retardant and self-extinguishing function is obtained.

[0032] Table 1 embodiment 2 high elastic polyacrylate resin performance index

[0033]

[0034]

[0035] Table 2 Manufacturers and batch numbers of raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com