A kind of fast-drying ultraviolet light curing coating

A technology for curing coatings and ultraviolet light, which is applied in the direction of polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as slow curing speed, consumption of free radicals, and impact on polymerization reactions, so as to reduce energy efficiency and radiate energy. , the effect of high coagulation content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

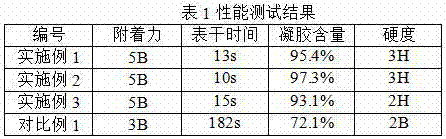

Embodiment 1

[0032] A UV-curable coating consisting of the following components by weight percentage:

[0033] Hyperbranched polyester acrylic resin 18%; difunctional aromatic polyether urethane acrylate 25%; 2-phenoxyethyl acrylate 14%; diethylene glycol divinyl ether 12%; ethylene glycol Diglycidyl ether 13%; photoinitiator 0.8%; BYK354 0.5%; BYK141 0.5%; Tego 655 0.5%; supplement to 100% with butyl acetate.

Embodiment 2

[0035] A UV-curable coating consisting of the following components by weight percentage:

[0036] Hyperbranched polyester acrylic resin 15%; difunctional aromatic polyether urethane acrylate 29%; 2-phenoxyethyl acrylate 12%; diethylene glycol divinyl ether 15%; ethylene glycol Diglycidyl ether 11%; photoinitiator 1%; BYK354 0.5%; BYK141 0.5%; Tego 655 0.5%; supplement to 100% with n-butanol.

Embodiment 3

[0038] A UV-curable coating consisting of the following components by weight percentage:

[0039] Hyperbranched polyester acrylic resin 19%; difunctional aromatic polyether urethane acrylate 19%; 2-phenoxyethyl acrylate 13%; diethylene glycol divinyl ether 9%; ethylene glycol Diglycidyl ether 11%; photoinitiator 0.5%; BYK354 0.5%; BYK141 0.5%; Tego 655 0.5%; supplement to 100% with ethyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com