A kind of Klebsiella producing β-galactosidase and its application

A technology of Klebsiella and galactosidase, which is applied in the field of microorganism isolation and cultivation, can solve the problems of lack of resources of excellent natural strains and low enzyme activity of β-galactosidase, and achieve the same ability and strong transformation The effect of glycoside activity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

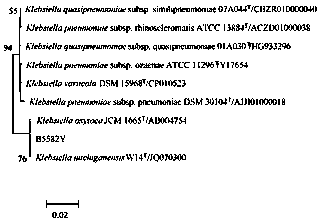

[0053] Example 1 Klebsiella B5582Y screening isolation and identification

[0054] 1. Klebsiella ( Klebsiella michiganensis ) B5582Y screening isolation

[0055] Weigh 0.1g of the soil sample collected near Jinlier Dairy Factory in Xinxiang City, Henan Province, put it into a 1.5mL PE small tube filled with sterile water and shake it evenly; then dilute it with sterile water to the volume concentration 1×10 -4 , 1×10 -5 Two gradient dilutions; use sterilized pipette tips to pipette 100μL of different gradient dilutions and spread them on the pre-prepared, sterilized and coated with 40mL 20mg / mL x-gal screening plate medium, at 37℃ Cultivate for 24-36h. Pick a single colony with a blue hydrolysis circle from the screening plate medium, separate the single colony by streaking, and check the part of the single colony in the microscopic examination to determine the purity of the strain (microscopic observation of the bacteria shows the same morphological characteristics) . ...

Embodiment 2

[0072] Example 2 Preparation and fermentation optimization of fermentation broth containing β-galactosidase and Klebsiella B5582Y

[0073] 1. Incline cultivation

[0074] Klebsiella B5582Y was inoculated on the slant medium and cultured at 37°C for 24 hours to obtain the slant strain.

[0075] 2. Liquid Proliferation Culture and Fermentation

[0076] Pick 2 loops of the obtained slant strain and insert them into the proliferation medium, and cultivate them at 37°C and 180rpm for 24 hours to obtain the proliferation bacteria liquid; the proliferation bacteria liquid is inserted into a 50mL basic fermentation tank with an inoculation amount of 2% (v / v). culture medium in a 250 mL Erlenmeyer flask at 37°C and 180 rpm for 24 hours to obtain a fermentation broth.

[0077] 3. Optimization of fermentation medium and fermentation conditions

[0078] On the basis of the basic fermentation medium, the type and concentration of carbon source, the type and concentration of nitrogen sou...

Embodiment 3

[0079] Example 3 Confirmation of β-galactosidase and measurement of enzyme activity

[0080] 1. Preparation of crude enzyme solution

[0081] Centrifuge the fermentation broth obtained in Example 2 at 4°C and 8000 rpm for 10 min, wash and centrifuge the cell pellet with PBS buffer solution (sodium salt) of pH 6.7, and then add the same volume of pH 6.7 PBS buffer solution, sonicate in an ice-water bath (500W, ultrasonic 1.5s, intermittent 2s) for 10min, then centrifuge at 4°C, 8000rpm for 10min, and take the supernatant as β-galactosidase crude enzyme solution.

[0082] 2. Determination of β-galactosidase hydrolase activity

[0083] Accurately weigh a certain amount o NPG powder, prepared 2 mg / mL with 0.05 mol / L, pH 6.7 PBS buffer o NPG solution; take 2mL o The NPG solution was placed in a test tube, incubated at 50°C for 10 min, and then added with 0.5 mL for proper dilution so that after the final reaction, the OD value of the solution to be tested was between 0.2 and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com