Fermented feed for improving animal production performance and/or feed utilization rate and application thereof

A fermented feed and feed additive technology, applied in the field of fermentation, can solve the problems of poor water solubility, lower utilization rate of corn gluten powder, low digestible utilization rate, etc., and achieve higher utilization rate, higher digestible utilization rate, digestible utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

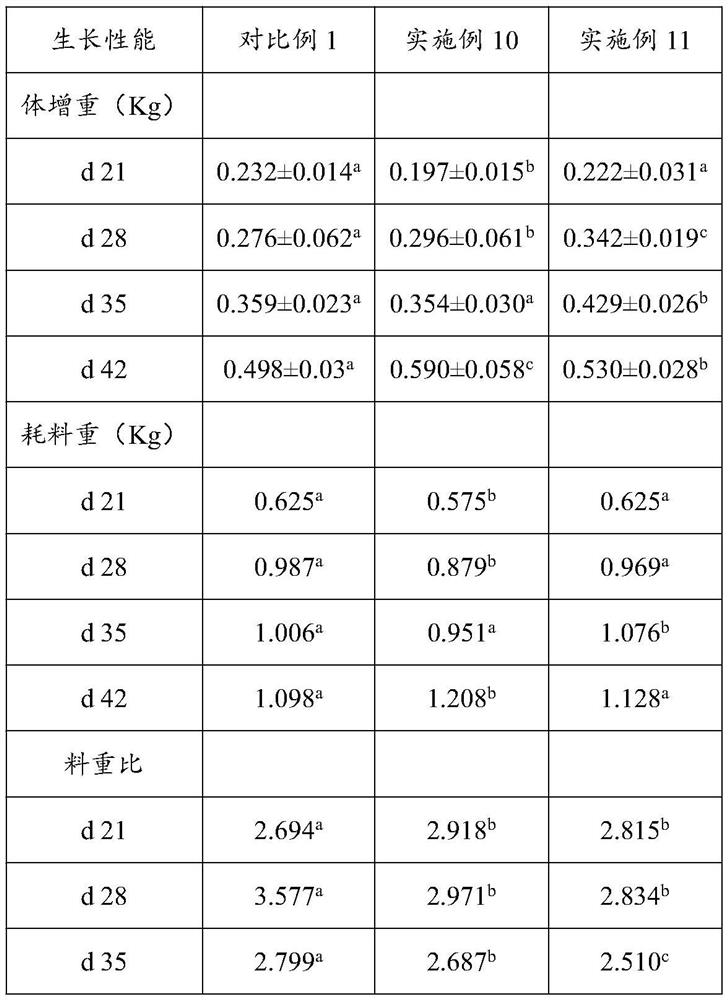

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of the feed additive described in the above scheme, comprising the following steps:

[0045] The base material, the mixed bacteria are mixed with water, and the anaerobic fermentation is carried out for 3.5-9 days to obtain the feed additive.

[0046] The invention mixes the bottom material, the mixed bacteria and water, and performs anaerobic fermentation for 3.5-9 days to obtain the feed additive. In the present invention, when the base material is base material 1, the preparation of the fermentation material preferably further includes adding crystallized glucose mother liquor. The present invention has no special requirements on the mixing method, and a mixing method well known to those skilled in the art can be used.

[0047] In the present invention, the time of the anaerobic fermentation is 3.5~9d, more preferably 3.5~7d, most preferably 3.5~5d; the temperature of the anaerobic fermentation is preferably 2...

Embodiment 1

[0059] A mixed bacterial agent for fermented feed, prepared according to the following mass parts: 3 parts of Lactobacillus (preservation number CGMCC No. 13110), 2 parts of Saccharomyces cerevisiae (preservation number CGMCC No. 21353) and 1 part of Bacillus subtilis (preservation number for CGMCC No.21352).

[0060] The preparation of this mixed bacterial agent is:

[0061] Activate Lactobacillus, Saccharomyces cerevisiae and Bacillus subtilis respectively, then inoculate the activated strains into the corresponding liquid medium for shaker culture (200r / min), the culture dimension is 30°C; culture to logarithmic growth period, the seed liquid obtained (the effective number of viable bacteria of the three kinds of bacteria in different seed liquids were 1×10 9 CFU / mL); finally, mixed according to the above volume ratio to obtain a mixed bacterial agent.

[0062] The activation medium of Bacillus subtilis is LB medium, specifically 10g tryptone, 5g yeast extract, 10g sodium...

Embodiment 2

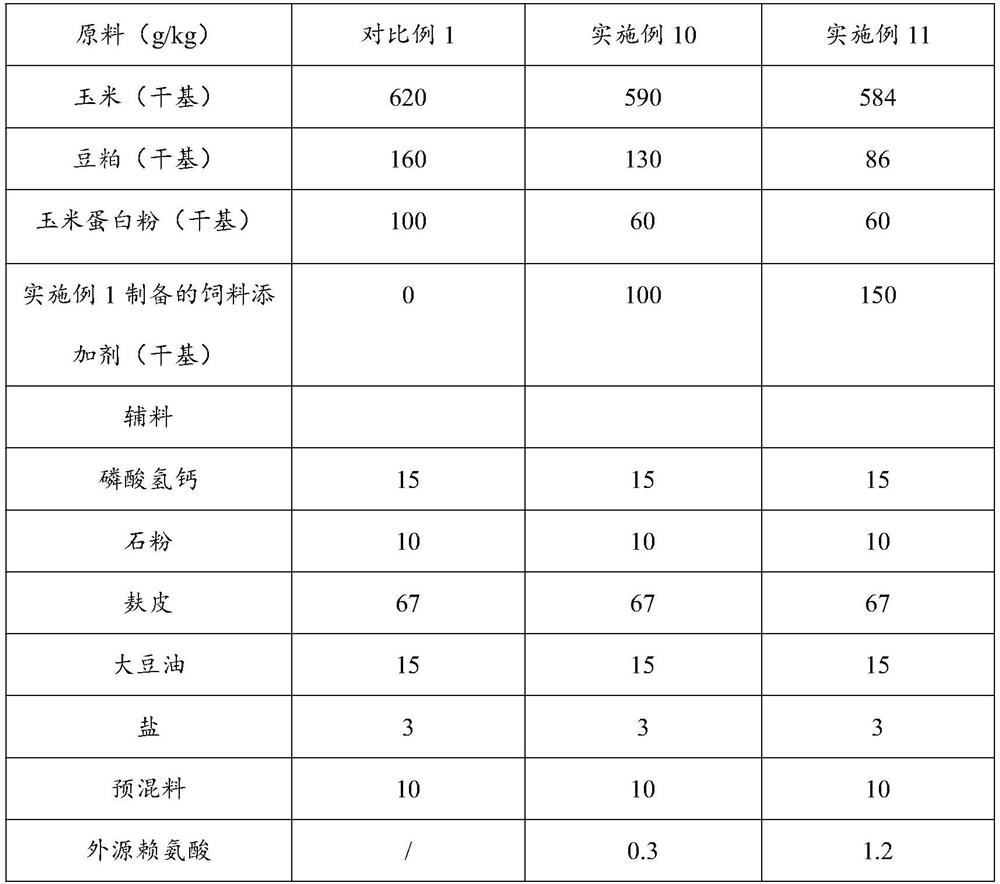

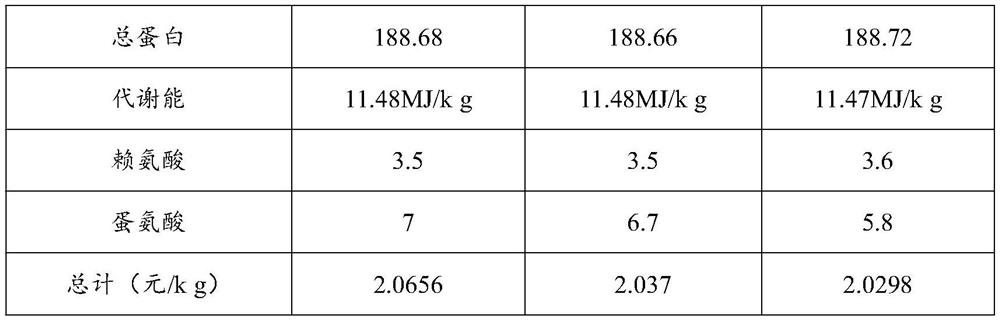

[0066] A feed additive prepared according to the following parts by mass: 5 parts of corn gluten powder, 4 parts of corn germ meal, 1 part of sprayed corn bran, 0.5 part of the mixed bacterial agent prepared in Example 1, and 0.5 part of crystalline glucose mother liquor.

[0067] The preparation of this feed additive is:

[0068] Mix 5 kg of corn gluten powder, 4 kg of corn germ meal, 1 kg of sprayed corn husk, 0.5 kg of the mixed bacterial agent prepared in Example 1, 0.5 kg of crystallized glucose mother liquor and 12 L of water, mix them evenly, and put them into a one-way valve fermentation bag to seal. Ferment at 30°C, and perform a bag-turning operation on the second day of fermentation. After bag expansion, the fermentation is completed in 3 days to obtain the feed additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com