Deodorizing and fertility-increasing organic material decomposition maturing agent and preparation method and application thereof

A technology of organic material and decomposing agent, applied in the field of preparation of organic material decomposing agent and organic material decomposing agent, can solve the problems of surrounding environment pollution, reducing fertilizer efficiency of composting products, loss of nitrogen of composting materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

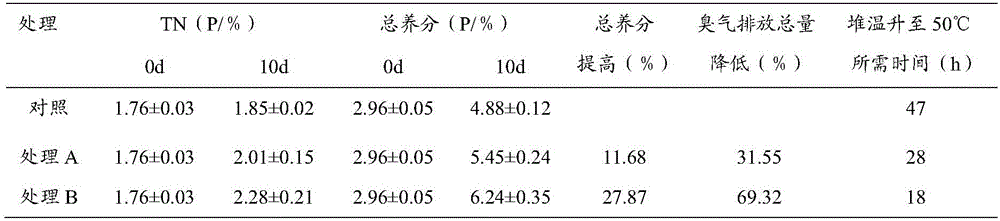

Embodiment 1

[0098] Embodiment 1: prepare organic material decomposing agent

[0099] The implementation steps of this embodiment are as follows:

[0100] I, prepare composite microbial bacterial agent A

[0101] Preparation of nitrogen-fixing bacillus bacterial agent: take the original species of nitrogen-fixing bacillus LXB4XX4 preserved at -80°C, transfer it to beef extract peptone medium, activate and cultivate it at a constant temperature at 37°C for 2 days, and then use "Bacillus subtilis solid-state The solid-state culture process described in "Fermentation Process Research" is used for shallow-pan solid-state fermentation expansion culture, and the obtained fermented product is dried to a water content of 11.56% by weight at a temperature of 35-40°C, and crushed to obtain a fineness of ≥70%. , 11 billion cfu / g of nitrogen-fixing bacillus bacteria agent;

[0102] Preparation of Saccharomyces cerevisiae inoculum: Take the original Saccharomyces cerevisiae strains preserved at -80°C...

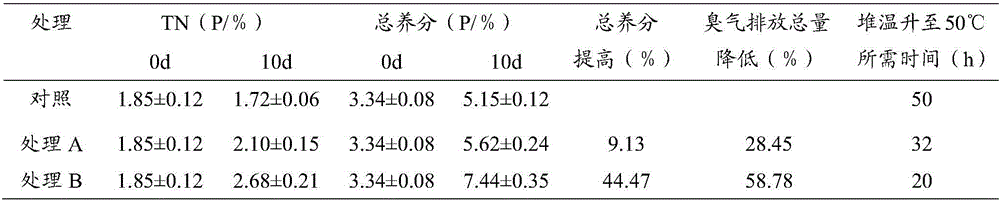

Embodiment 2

[0111] Embodiment 2: Preparation of organic material decomposing agent

[0112] The implementation steps of this embodiment are as follows:

[0113] I, prepare composite microbial bacterial agent A

[0114] Preparation of nitrogen-fixing bacillus bacterial agent: take the original species of nitrogen-fixing bacillus LXB4XX4 preserved at -80°C, transfer it to beef extract peptone medium, activate and cultivate it at a constant temperature at 37°C for 2 days, and then use "Bacillus subtilis solid-state The solid-state culture process described in "Fermentation Technology Research" is used to carry out shallow-pan solid-state fermentation expansion culture, and the obtained fermented product is dried to a water content of 10.86% by weight at a temperature of 35-40°C, and crushed to obtain a fineness of ≥70%. , 10.2 billion cfu / g of nitrogen-fixing bacillus bacterial agent;

[0115] Preparation of Saccharomyces cerevisiae inoculum: take the original Saccharomyces cerevisiae stra...

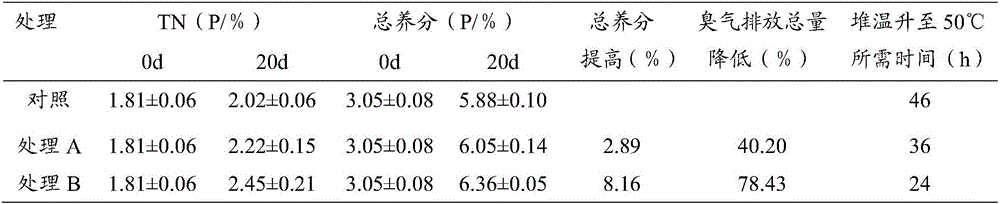

Embodiment 3

[0124] Embodiment 3: prepare organic material decomposing agent

[0125] The implementation steps of this embodiment are as follows:

[0126] I, prepare composite microbial bacterial agent A

[0127] Preparation of nitrogen-fixing bacillus bacterial agent: take the original species of nitrogen-fixing bacillus LXB4XX4 preserved at -80°C, transfer it to beef extract peptone medium, activate and cultivate it at a constant temperature at 37°C for 2 days, and then use "Bacillus subtilis solid-state The solid-state culture technology described in "Fermentation Technology Research" is used to carry out shallow-pan solid-state fermentation expansion culture, and the fermented product obtained is dried at a temperature of 35-40 °C until the water content is 12.66% by weight, and then crushed to obtain a fineness ≥ 70%. , 10.9 billion cfu / g of nitrogen-fixing bacillus bacteria agent;

[0128] Preparation of Saccharomyces cerevisiae inoculum: Take the original Saccharomyces cerevisiae ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com