Preparation method of difunctional nanometer enzyme for visual glucose detection

A nano-enzyme and dual-function technology, applied in the chemical field, can solve the problems of low activity, difficult separation, and easy oxidation of biological enzymes, and achieve the effects of high catalytic activity, good selectivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

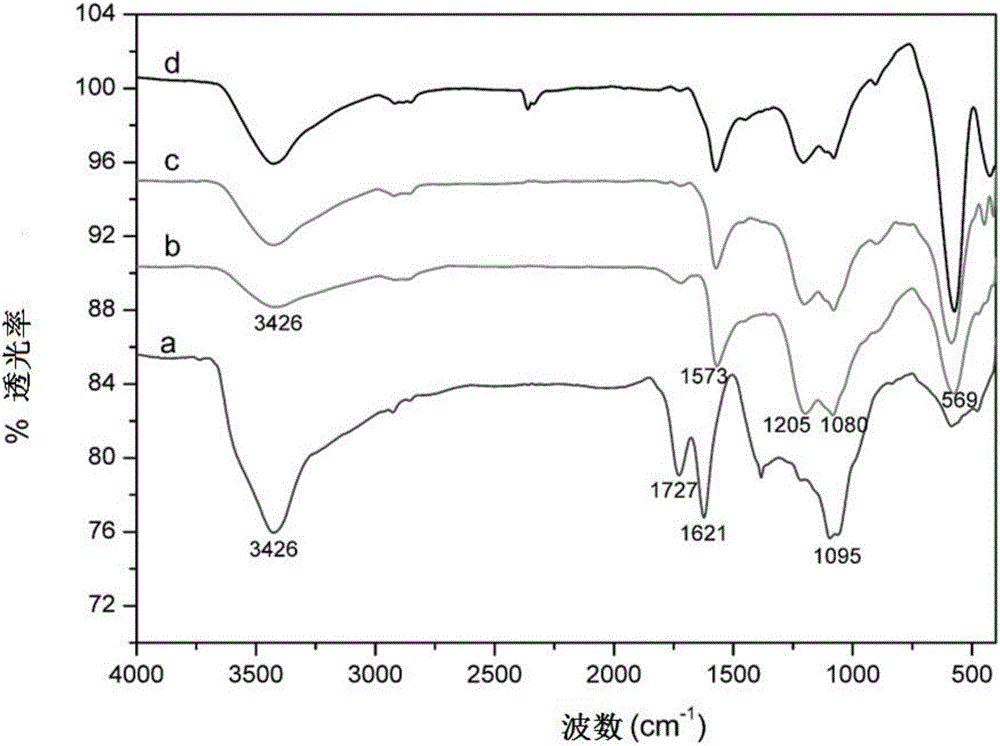

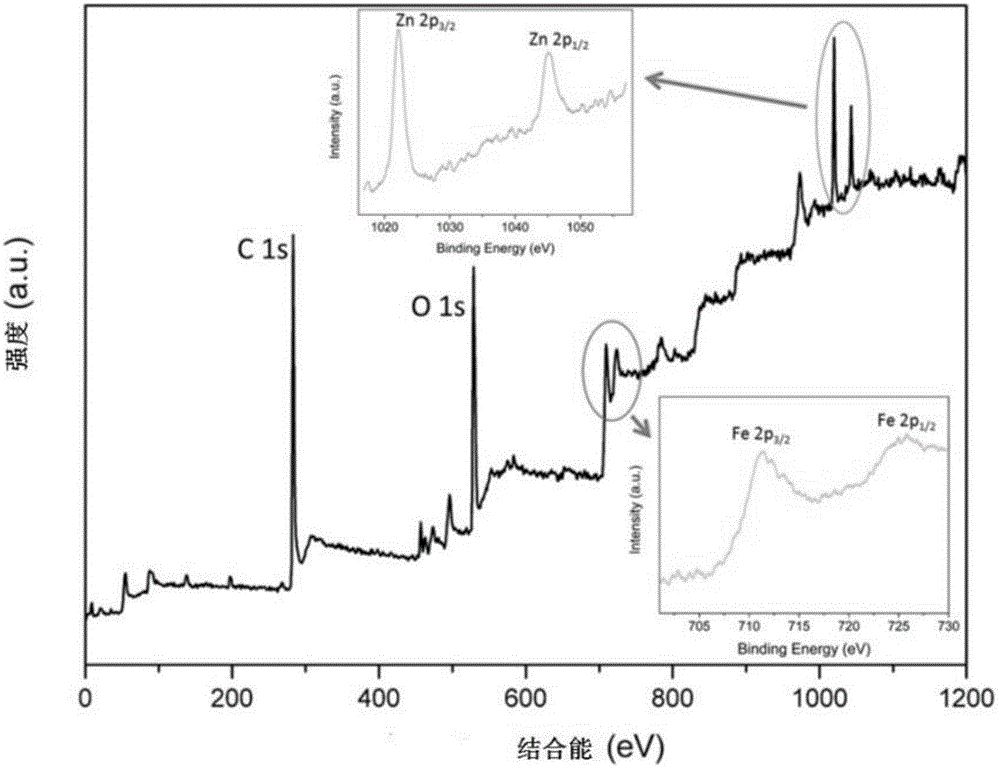

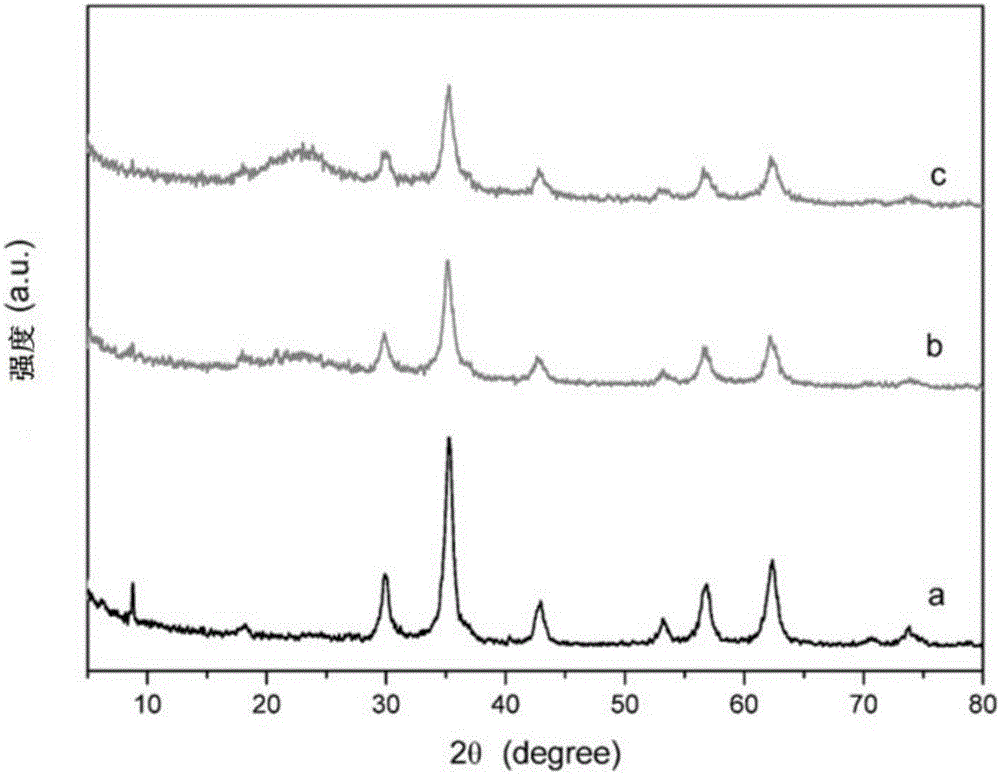

[0035] (1) rGO-ZnFe 2 o 4 Synthesis of nanozymes

[0036] A. First weigh 1.0g of graphite powder in a mortar, add 50g of NaCl solid, grind for 10 minutes, add water to dissolve, filter, wash, and then remove NaCl. Transfer the treated graphite powder to a round bottom flask, add 23 mL concentrated H 2 SO 4 , stirred at room temperature for 8 hours. Then place the round bottom flask in an ice-water bath, slowly add 3.0g KMnO 4 Solid, stirred at 35-40°C for 30 minutes, then stirred at 65-80°C for 45 minutes. Then 46 mL of water was added and stirring was continued for 30 minutes at 98-105°C. Finally, add 140 mL of water and 10 mL of 30% H 2 o 2 The reaction was terminated, and the color of the solution turned bright yellow. The obtained product was washed with 5% HCl, then washed with ultrapure water, centrifuged (12000 rpm), and this process was repeated until it could not be separated by centrifugation. Then the obtained yellow suspension was transferred to a dialysi...

Embodiment 2

[0039] A. First weigh 1.0g of graphite powder in a mortar, add 50g of NaCl solid, grind for 10 minutes, add water to dissolve, filter, wash, and then remove NaCl. Transfer the treated graphite powder to a round bottom flask, add 23 mL concentrated H 2 SO 4 , stirred at room temperature for 8 hours. Then place the round bottom flask in an ice-water bath, slowly add 3.0g KMnO 4 Solid, stirred at 35-40°C for 30 minutes, then stirred at 65-80°C for 45 minutes. Then 46 mL of water was added and stirring was continued for 30 minutes at 98-105°C. Finally, add 140 mL of water and 10 mL of 30% H 2 o 2 The reaction was terminated, and the color of the solution turned bright yellow. The obtained product was washed with 5% HCl, then washed with ultrapure water, centrifuged (12000 rpm), and this process was repeated until it could not be separated by centrifugation. Then the obtained yellow suspension was transferred to a dialysis bag, and dialyzed in ultrapure water for one week un...

Embodiment 3

[0042] A. First weigh 1.0g of graphite powder in a mortar, add 50g of NaCl solid, grind for 10 minutes, add water to dissolve, filter, wash, and then remove NaCl. Transfer the treated graphite powder to a round bottom flask, add 23 mL concentrated H 2 SO 4 , stirred at room temperature for 8 hours. Then place the round bottom flask in an ice-water bath, slowly add 3.0g KMnO 4 Solid, stirred at 35-40°C for 30 minutes, then stirred at 65-80°C for 45 minutes. Then 46 mL of water was added and stirring was continued for 30 minutes at 98-105°C. Finally, add 140 mL of water and 10 mL of 30% H 2 o 2 The reaction was terminated, and the color of the solution turned bright yellow. The obtained product was washed with 5% HCl, then washed with ultrapure water, centrifuged (12000 rpm), and this process was repeated until it could not be separated by centrifugation. Then the obtained yellow suspension was transferred to a dialysis bag, and dialyzed in ultrapure water for one week un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com