Acotiamide hydrochloride membrane controlled slow release preparation and preparation method thereof

A technology for acotiamide hydrochloride and sustained-release preparations, which is applied in the field of acotiamide hydrochloride film-controlled sustained-release preparations and its preparation, can solve the problems of easy forgetting and poor compliance, and achieve the goal of improving solubility and dissolution rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

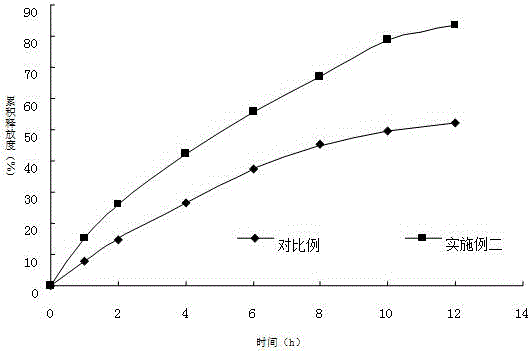

Image

Examples

Embodiment 1

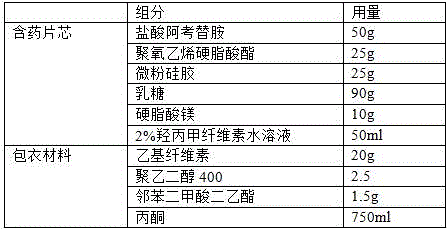

[0018] A film-controlled sustained-release preparation of acotiamide hydrochloride is composed of highly soluble acotiamide hydrochloride intermediates and coating components; it includes the following raw materials in parts by weight:

[0019] Table 1 Formula for preparing 1000 drug-containing tablet cores

[0020]

[0021] Its preparation process is:

[0022] (1) Preparation of highly soluble acotiamide hydrochloride intermediate: Dissolve acotiamide hydrochloride in 2.5 times the volume of ethanol solution, add polyoxyethylene stearate melted in a water bath at 60~70°C, mix and stir Evenly, dry in a vacuum oven at 40°C for 24 hours;

[0023] (2) Preparation of drug-containing tablet cores: Take out the highly soluble acotiamide hydrochloride intermediate obtained in step (1), add the prescribed amount of micropowder silica gel to grind (micropowder silica gel as a lubricant can reduce the loss of solid dispersion during the grinding process ), passed through an 80-mesh...

Embodiment 2

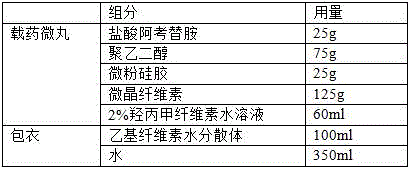

[0025] A film-controlled sustained-release preparation of acotiamide hydrochloride is composed of highly soluble acotiamide hydrochloride intermediates and coating components; it includes the following raw materials in parts by weight:

[0026] Table 2 The formula for preparing 1000 drug-loaded pellets

[0027]

[0028] Its preparation process is:

[0029] (1) Preparation of highly soluble acotiamide hydrochloride intermediate: Dissolve acotiamide hydrochloride in 1.5 times the volume of ethanol solution, add polyethylene glycol melted in a water bath at 60~70°C, mix and stir evenly, and place Dry in a vacuum oven at 40°C for 24 hours;

[0030] (2) Preparation of drug-loaded pellets: Take out the highly soluble acotiamide hydrochloride intermediate obtained in step (1), add the prescribed amount of micropowder silica gel to grind, pass through an 80-mesh sieve, and mix with lactose, microcrystalline cellulose, etc. Mix evenly by incremental method, add appropriate amount ...

Embodiment 3

[0032] A film-controlled sustained-release preparation of acotiamide hydrochloride is composed of highly soluble acotiamide hydrochloride intermediates and coating components; it includes the following raw materials in parts by weight:

[0033] Table 3 Formula for preparing 1000 drug-loaded pellets

[0034]

[0035] Its preparation process is:

[0036] Add an appropriate amount of microcrystalline cellulose to the binder to make a soft material, and use the extrusion spheronization method to prepare a blank pellet core (or directly use a commercially available blank pellet core); dissolve acotiamide hydrochloride in 1 volume of ethanol In the solution, after the polyethylene glycol is heated in a water bath at 60~70°C until it melts, mix and stir evenly, add 2% hypromellose aqueous solution and stir evenly, adopt the fluidized bed coating method, and dissolve the medicinal solution Spray on the surface of the blank pellet core to prepare drug-loaded pellets; after drying, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com