Neodymium and ytterbium co-doped quartz laser glass and preparation method thereof

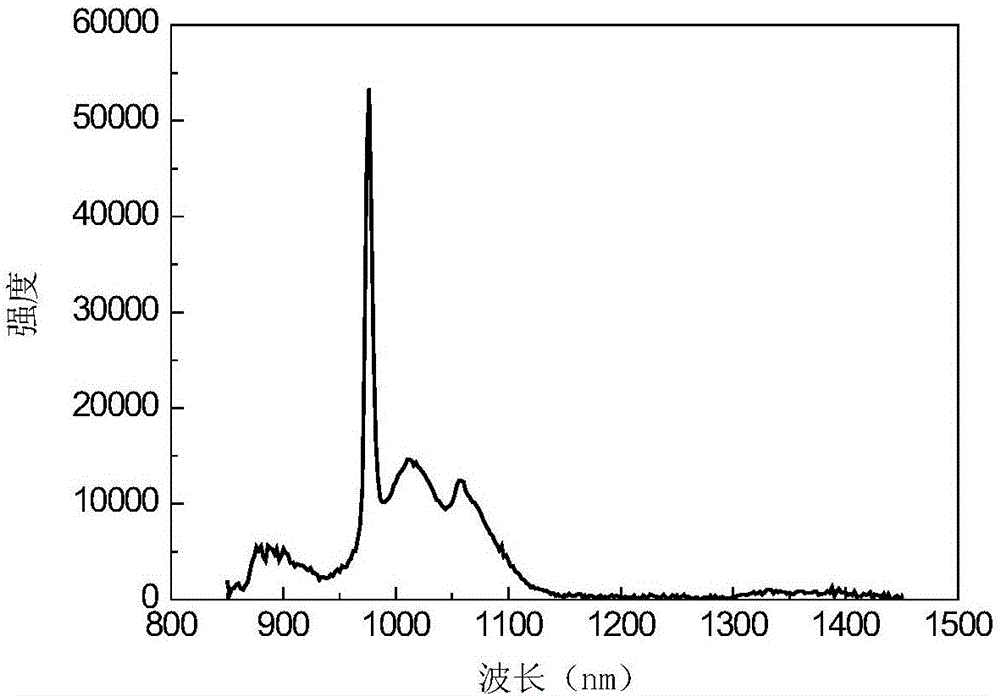

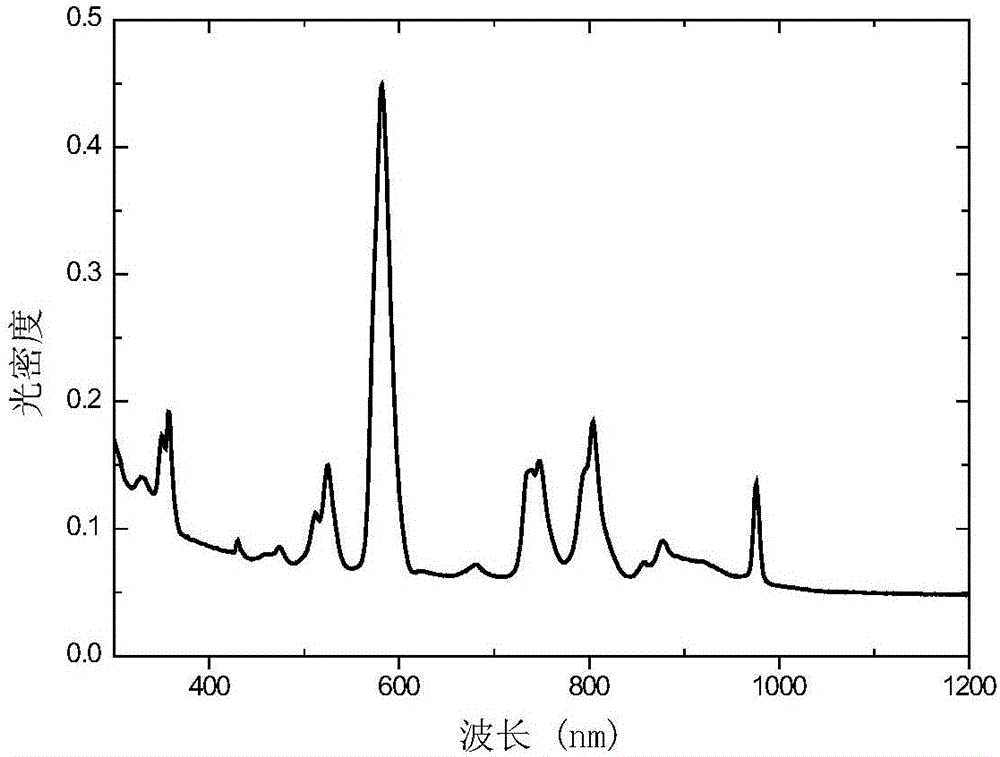

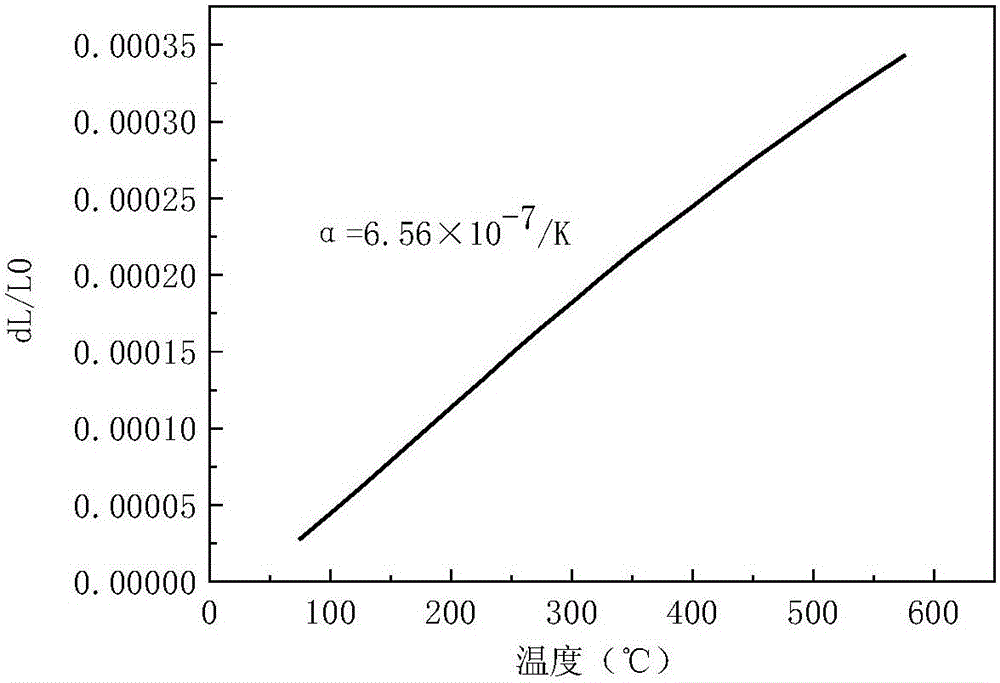

A laser glass and co-doping technology, applied in the field of neodymium-ytterbium co-doped quartz laser glass and its preparation, to achieve the effects of low thermal expansion coefficient and excellent high repetition frequency thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of embodiment 1 is as follows:

[0029] 1) Preparatory work: purchase undensified porous silica powder prepared by an external vapor deposition process from an optical fiber preform production enterprise. Prepare the solution: add a certain amount of aluminum chloride, ytterbium chloride, neodymium chloride, and phosphoric acid to dissolve in ethanol. In the solution, the concentration of ytterbium chloride is 0.02mol / L, and the concentration of neodymium chloride is 0.08mol / L. The molar ratio of the sum of ytterbium chloride and aluminum chloride to aluminum chloride is 1:10, and the concentration of phosphoric acid is 1mol / L, forming a mixed ethanol solution of aluminum chloride, ytterbium chloride, neodymium chloride and phosphoric acid;

[0030] 2) Doping by soaking method: soak the purchased silica porous powder in the mixed ethanol solution of aluminum chloride, ytterbium chloride, neodymium chloride and phosphoric acid for more than 30 minu...

Embodiment 2

[0034] The preparation method of embodiment 2 is as follows:

[0035] 1) Preparatory work: purchase undensified porous silica powder prepared by an external vapor deposition process from an optical fiber preform production enterprise. Prepare the solution: add a certain amount of aluminum chloride, ytterbium chloride, neodymium chloride, and phosphoric acid to dissolve in ethanol. In the solution, the concentration of ytterbium chloride is 0.01mol / L, and the concentration of neodymium chloride is 0.04mol / L. The molar ratio of the sum of ytterbium chloride and aluminum chloride to aluminum chloride is 1:10, and the concentration of phosphoric acid is 0.5mol / L, forming a mixed ethanol solution of aluminum chloride, ytterbium chloride, neodymium chloride and phosphoric acid;

[0036] 2) Doping by soaking method: soak the purchased silica porous powder in the mixed ethanol solution of aluminum chloride, ytterbium chloride, neodymium chloride and phosphoric acid for more than 30 mi...

Embodiment 3

[0040] The preparation method of embodiment 3 is as follows:

[0041]1) Preparatory work: purchase undensified porous silica powder prepared by an external vapor deposition process (OVD) from an optical fiber preform manufacturer. Prepare the solution: add a certain amount of aluminum chloride, ytterbium chloride, neodymium chloride, and phosphoric acid to dissolve in ethanol. In the solution, the concentration of ytterbium chloride is 0.01mol / L, and the concentration of neodymium chloride is 0.07mol / L. The molar ratio of the sum of ytterbium chloride and aluminum chloride to aluminum chloride is 1:10, and the concentration of phosphoric acid is 0.8mol / L, forming a mixed ethanol solution of aluminum chloride, ytterbium chloride, neodymium chloride and phosphoric acid;

[0042] 2) Doping by soaking method: soak the purchased silica porous powder in the mixed ethanol solution of aluminum chloride, ytterbium chloride, neodymium chloride and phosphoric acid for more than 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com