Special mortar modifying agent

A modifier and mortar technology, which is used as a modifier of various properties of mortars such as caulking agents, improves and improves the field of tile adhesive and putty, and can solve the problems of poor workability, low strength, and many surface pores. , to achieve the effect of improving compactness, improving construction performance, surface strength and surface effect

Inactive Publication Date: 2017-03-15

广东龙湖科技股份有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to overcome the above existing problems, the purpose of the present invention is to provide a special mortar modifier, which is used to solve the problems of existing ceramic tile adhesives, putty, caulking agents and other products with many internal and surface pores, low strength or poor workability. no problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

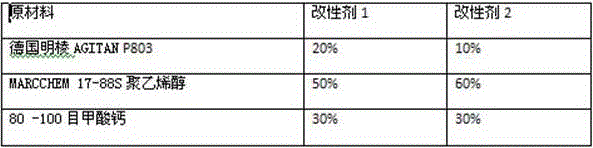

[0011] 1. Formula (by weight)

[0012]

[0013] 2. Preparation

[0014] After stirring each component evenly according to the above formula, the special mortar modifier 1 and the special mortar modifier 2 of the present invention are obtained.

[0015] 3. Application

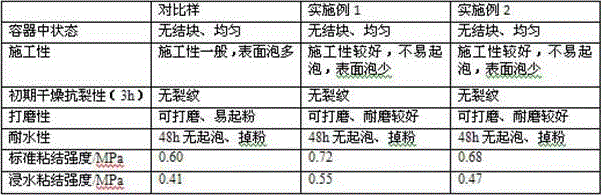

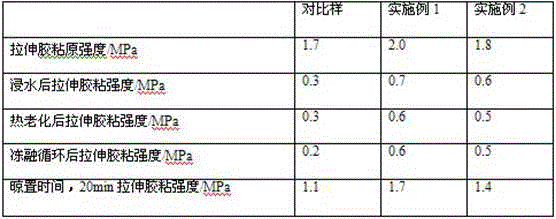

[0016] (1) Apply the above-mentioned special mortar additives to cement-based tile adhesives.

[0017] A. Formula (by weight)

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a modifying agent capable of improving and enhancing the properties of special mortars such as tile glue, putty and a caulking agent. The modifying agent is prepared from, by weight, 10%-30% of powdery antifoaming agent, 10%-30% of calcium formate and 40-60% of polyvinyl alcohol through mixture, wherein the powdery antifoaming agent is a mineral oil type antifoaming agent produced by Germany MingLing chemical group, the polyvinyl alcohol is cold soluble type polyvinyl alcohol with the polymerization of 1788 or 2488, the special mortar is a ceramic tile adhesive, putty or the caulking agent, and the adding amount of the modifying agent in the special mortar is 0.1-0.2% of the total weight of the special mortar. The adding amount of the modifying agent is very small. Exiting ceramic tile adhesives, putty, caulking agents and other products can obviously improve the compressive strength, surface strength and surface effect of the mortar without original formula and proportion change of the special mortar under the condition that the application property of the mortar is not affected, and the modifying agent is especially suitable for usage in ceramic tile adhesives, caulking agents and internal and external wall putty.

Description

technical field [0001] The invention relates to an additive for mortar, in particular to a modified admixture for special mortar, and more particularly to a modifier capable of improving and enhancing the properties of mortar such as tile adhesive, putty and caulking agent. Background technique [0002] The so-called special mortar refers to the mortar suitable for special requirements such as thermal insulation, sound absorption, waterproof, corrosion resistance, radiation protection, decoration and bonding. Special mortar has become a An indispensable building material in modern home decoration, such as commonly used tile adhesives, caulking agents, putty, etc. Among the problems, the most common one is that there are many internal and surface bubbles, resulting in low surface strength. The reasons for the generation of air bubbles in mortars such as tile adhesives, caulks, and putty are as follows: 1. The addition of cellulose ether, while providing water retention and t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/26C04B28/00

CPCC04B40/0039C04B28/00C04B2201/50C04B2103/50C04B24/04C04B24/2623C04B14/06C04B24/383C04B14/28C04B2103/65

Inventor 罗天翼黄丽圆刘双华洪永顺

Owner 广东龙湖科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com