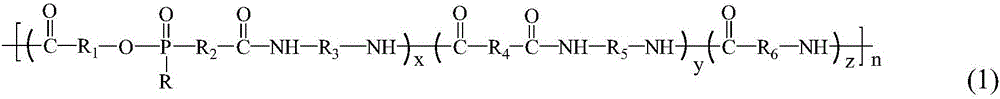

Organophosphorus copolymeric flame-retarded polyamide and preparation method thereof

A technology for copolymerizing flame retardant and organic phosphorus, which is applied in the field of flame retardant polymer synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

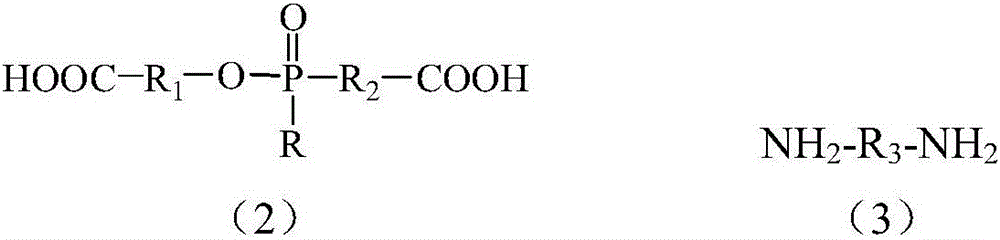

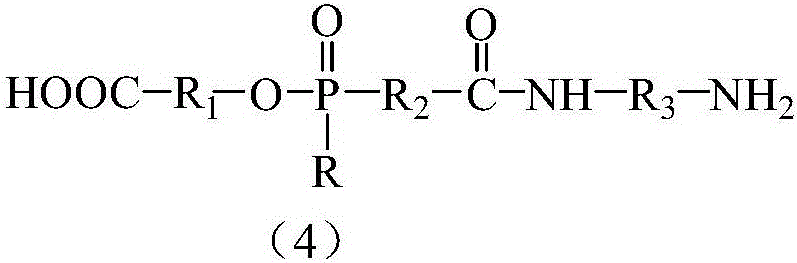

[0062] The preparation method of the organophosphorus copolymerized flame-retardant polyamide of the present invention specifically comprises the following steps:

[0063] (A) reacting an organophosphorus flame retardant monomer with a diamine, preferably making the amino group excessive, to generate a salt solution;

[0064] (B) reacting the reaction product of step (A) with diacid, diamine or dibasic amide salt and lactam to produce organophosphorus copolymerized flame-retardant polyamide.

[0065] In step (A), preferably, the diamine monomer is slightly excessive, so that the pH of the salt solution is 7-9. The reaction temperature rose from room temperature to 40-70°C within 5-20 minutes.

[0066] Preferably, the diamine monomers used in step (A) are hexamethylenediamine, decanediamine, nonanediamine, undecanediamine, dodecanediamine, aliphatic C 6 -C 20 One or more of iminodiamine, aromatic diamine, and alicyclic diamine.

[0067] In step (B), preferably, the polymeri...

Embodiment 1

[0081] Stir and react the flame retardant monomer and hexamethylenediamine in an aqueous solution at a molar ratio of 1:1.2 at 60°C for 0.5 h, adjust the pH of the solution to 7.2, and dry to form a salt. Nylon 66 salt (hexamethylene adipamide salt) solution and caprolactam with a molar ratio of 1:1, the above-mentioned salt that accounts for 6.0% of the total mass of the two, catalyst sodium hypophosphite, antioxidant The agent p-phenylenediamine and 40% deionized water were added to the reactor, vacuumed and filled with nitrogen for 5 times, and finally the internal pressure of the reactor was kept at 0.2MPa. Heat the reactor, keep stirring at a high speed, and when the temperature of the reactor reaches 220°C and the pressure is 1.8 MPa, keep the temperature and pressure constant for 1.5 hours. Then the temperature was raised to 250°C, and the pressure was released to normal pressure within 1 hour. Vacuumize to -0.05MPa. After the stirring speed drops to a certain value an...

Embodiment 2

[0084] Stir and react the flame retardant monomer and hexamethylenediamine in an aqueous solution at a molar ratio of 1:1.3 at 45°C for 1 hour, adjust the pH of the solution to 7.8, and dry to form a salt. Adipic acid and hexamethylenediamine are configured according to a mass ratio of 1:1.2, and caprolactam with adipic acid molar ratio of 1:0.6 and 7% of the total weight of adipic acid, hexamethylenediamine and caprolactam The salt obtained above, the catalyst toluenesulfonic acid each accounting for 1‰, the antioxidant 2,6-di-tert-butyl-4-methylphenol, and the deionized water accounting for 35% were added to the reactor, Vacuumize, fill with nitrogen 3 times, and finally keep the pressure in the reactor at 0.3MPa. Heat the reactor, keep stirring at a high speed, and when the temperature of the reactor reaches 215°C and the pressure is 1.7 MPa, keep the temperature and pressure constant for 1.6 hours. Then the temperature was raised to 240°C, and the pressure was released to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com