Rubber-plastic foam insulation material masterbatch and method for preparing rubber-plastic foam insulation material

A thermal insulation material, rubber and plastic foaming technology, applied in the field of rubber and plastic foam thermal insulation material masterbatch and preparation of rubber and plastic foam thermal insulation material, can solve the problems that the content of short-chain chlorinated paraffin and azodicarbonamide is easy to exceed the standard, etc. Improve the anti-aging performance and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

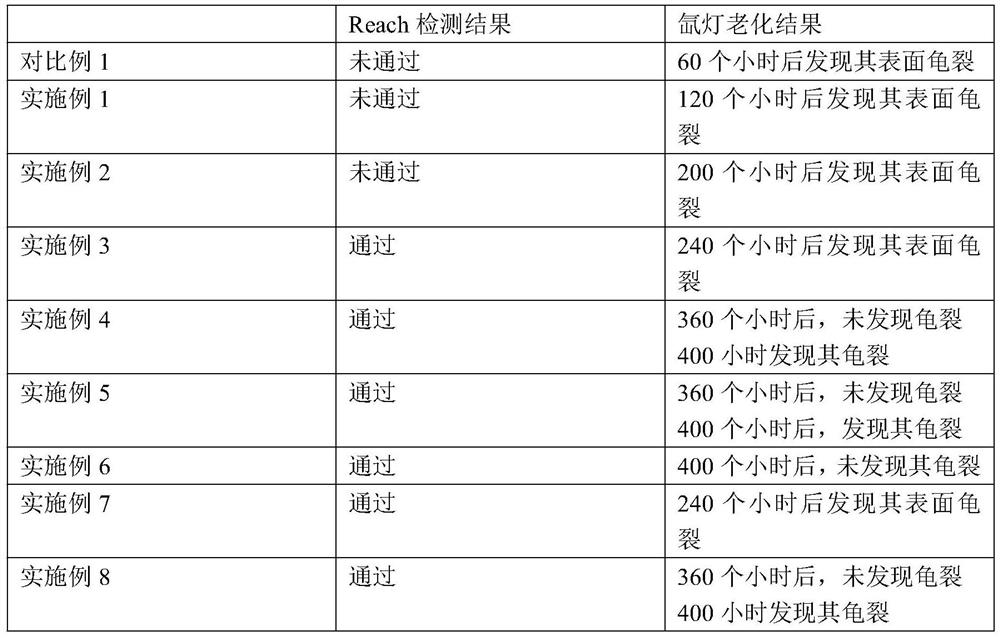

Examples

Embodiment 1

[0036] Embodiment 1. A kind of masterbatch of rubber and plastic foam insulation material comprises following components:

[0037] Main material: 8 parts of NBR, 15 parts of PVC, 7 parts of chlorinated paraffin

[0038] Anti-aging plasticizer: 7 parts of dipropylheptyl phthalate

[0039] Anti-aging modifier: 7 parts of butyl rubber

[0040] Flame retardant: 18 parts of aluminum hydroxide, 9 parts of magnesium hydroxide, 1 part of antimony trioxide

[0041] Foaming agent: 12 parts of azodicarbonamide

[0042] Filler: 10 parts of talcum powder, 3 parts of clay, 1 part of calcium carbonate, 1 part of calcium stearate

[0043] Anti-aging agent: 0.4 parts of anti-aging agent MB, 0.6 parts of anti-aging agent RD

[0044] The rubber-plastic foam insulation material master batch in the present embodiment is made into rubber-plastic foam insulation material according to the following preparation method:

[0045] 1. Put nitrile rubber, polyvinyl chloride, chlorinated paraffin and a...

Embodiment 2

[0051] Embodiment 2. A kind of masterbatch of rubber and plastic foaming thermal insulation material, comprises following component:

[0052] Main material: 8 parts of NBR, 15 parts of PVC, 7 parts of chlorinated paraffin

[0053] Anti-aging plasticizer: 7 parts of dipropylheptyl phthalate

[0054] Anti-aging modifier: 7 parts of EPDM rubber

[0055] Flame retardant: 18 parts of aluminum hydroxide, 9 parts of magnesium hydroxide, 1 part of antimony trioxide

[0056] Foaming agent: 12 parts of azodicarbonamide

[0057] Filler: 10 parts of talcum powder, 3 parts of clay, 1 part of calcium carbonate, 1 part of calcium stearate

[0058] Anti-aging agent: 0.4 parts of anti-aging agent MB, 0.6 parts of anti-aging agent RD

[0059] In this example, the masterbatch is weighed according to the above components, and the rubber-plastic foam insulation material is prepared according to the preparation method of Example 1.

Embodiment 3

[0060] Embodiment 3. A kind of masterbatch of rubber and plastic foaming thermal insulation material, comprises following component:

[0061] Main material: NBR8 parts, PVC15 parts,

[0062] Anti-aging plasticizer: 14 parts of dipropylheptyl phthalate

[0063] Anti-aging modifier: 7 parts of butyl rubber

[0064] Flame retardant: 18 parts of aluminum hydroxide, 9 parts of magnesium hydroxide, 1 part of antimony trioxide

[0065] Foaming agent: 12 parts of azodicarbonamide

[0066] Filler: 10 parts of talcum powder, 3 parts of clay, 1 part of calcium carbonate, 1 part of calcium stearate

[0067] Anti-aging agent: 0.4 parts of anti-aging agent MB, 0.6 parts of anti-aging agent RD

[0068] In this example, the masterbatch is weighed according to the above components, and the rubber-plastic foam insulation material is prepared according to the preparation method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com