Water-borne pressure sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, water-based technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve problems such as environmental pollution, and achieve the effect of high peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

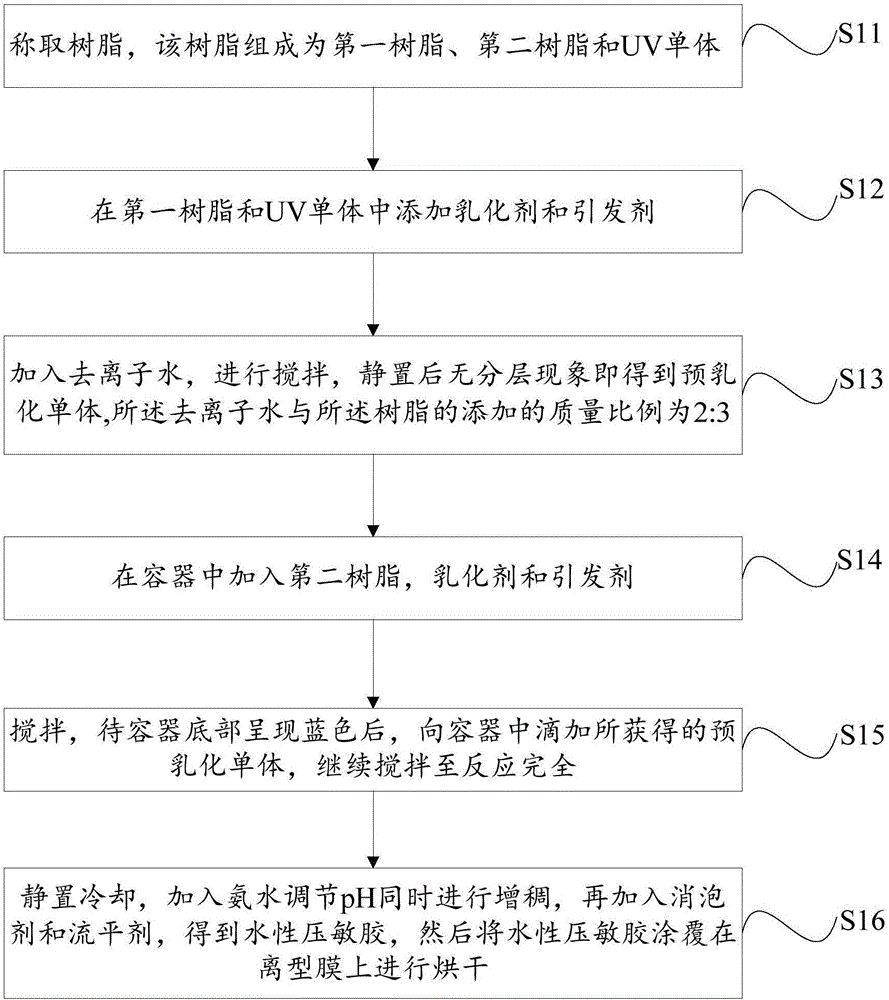

[0028] The present invention also provides the preparation method of the water-based pressure-sensitive adhesive, please refer to figure 1 , the preparation method comprises the steps of:

[0029] S11: Weighing the resin, the resin is composed of a first resin, a second resin and a UV monomer.

[0030] Wherein, when the UV monomer is hexanediol diacrylate, the quality of hexanediol diacrylate is 3.5-8% of the total mass of the resin; when the UV monomer is trimethylol propane tripropionate, the trihydroxy The mass of methylpropane tripropionate is 2-7% of the total mass of the resin, and when the UV monomer is triethylene glycol dimethacrylate, the mass of triethylene glycol dimethacrylate is 2.5% of the total mass of the resin -6%;

[0031] S12: adding an emulsifier and an initiator to the first resin and the UV monomer.

[0032] S13: Adding deionized water, and then stirring, and obtaining pre-emulsified monomer without delamination after standing still, the mass ratio of...

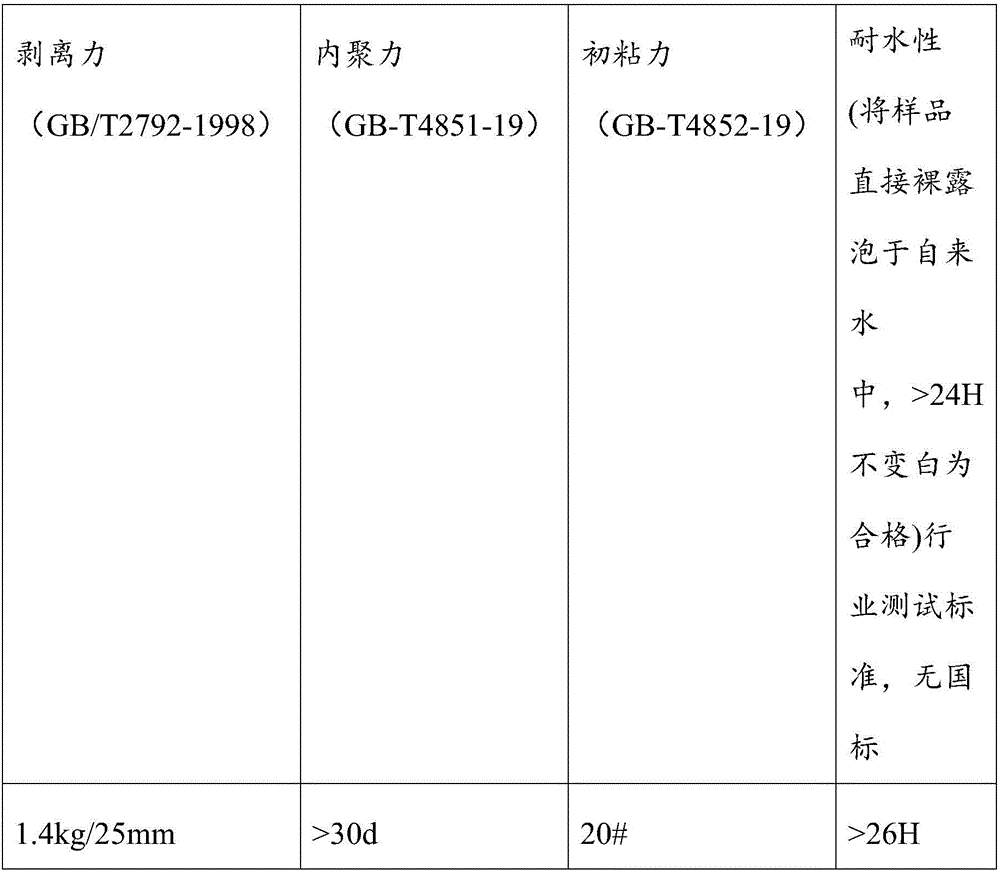

Embodiment 1

[0040] The resin is weighed, and the resin is composed of a first resin, a second resin and a UV monomer. The first resin composition is: methyl methacrylate, acrylic acid, butyl acrylate, and ethyl acrylate. The second resin composition is: butyl acrylate and methyl methacrylate.

[0041] In the first step, the first resin and UV monomer are pre-emulsified. The emulsifier is BYK306, and the addition amount is 1% of the total amount of the resin; the initiator is ammonium persulfate, and the addition amount is 1% of the total amount of the resin. 2.5%.

[0042] In the first resin, the addition of methyl methacrylate is 30% of the total amount of the resin, the addition of acrylic acid is 1% of the total amount of the resin; the addition of butyl acrylate is the total amount of the resin 42%, the addition of ethyl acrylate is 16% of the total amount of the resin;

[0043] The UV monomer is hexanediol diacrylate, and the addition amount is 3.5% of the total amount of the resi...

Embodiment 2

[0050] The resin is weighed, and the resin is composed of a first resin, a second resin and a UV monomer. The first resin composition is: methyl methacrylate, acrylic acid, butyl acrylate, and ethyl acrylate. The second resin composition is: butyl acrylate and methyl methacrylate.

[0051] In the first step, the first resin and UV monomer are pre-emulsified. The emulsifier is BYK306, and the addition amount is 1% of the total amount of the resin; the initiator is ammonium persulfate, and the addition amount is 1% of the total amount of the resin. 2.5%.

[0052] In the first resin, the addition of methyl methacrylate is 30% of the total amount of the resin, the addition of acrylic acid is 1% of the total amount of the resin; the addition of butyl acrylate is the total amount of the resin 40%, the addition of ethyl acrylate is 16% of the total amount of the resin;

[0053] The UV monomer is hexanediol diacrylate, the addition amount is 5.5% of the total amount of the resin, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com