Anti bacterial anti mite fiber and preparation method thereof

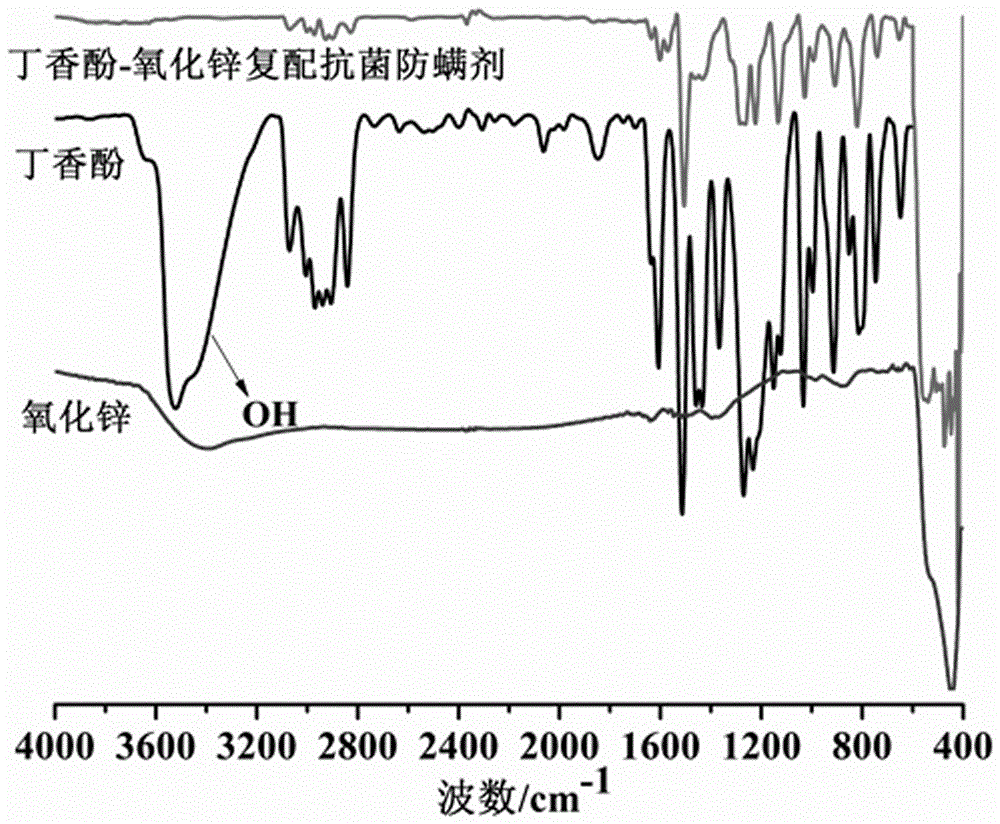

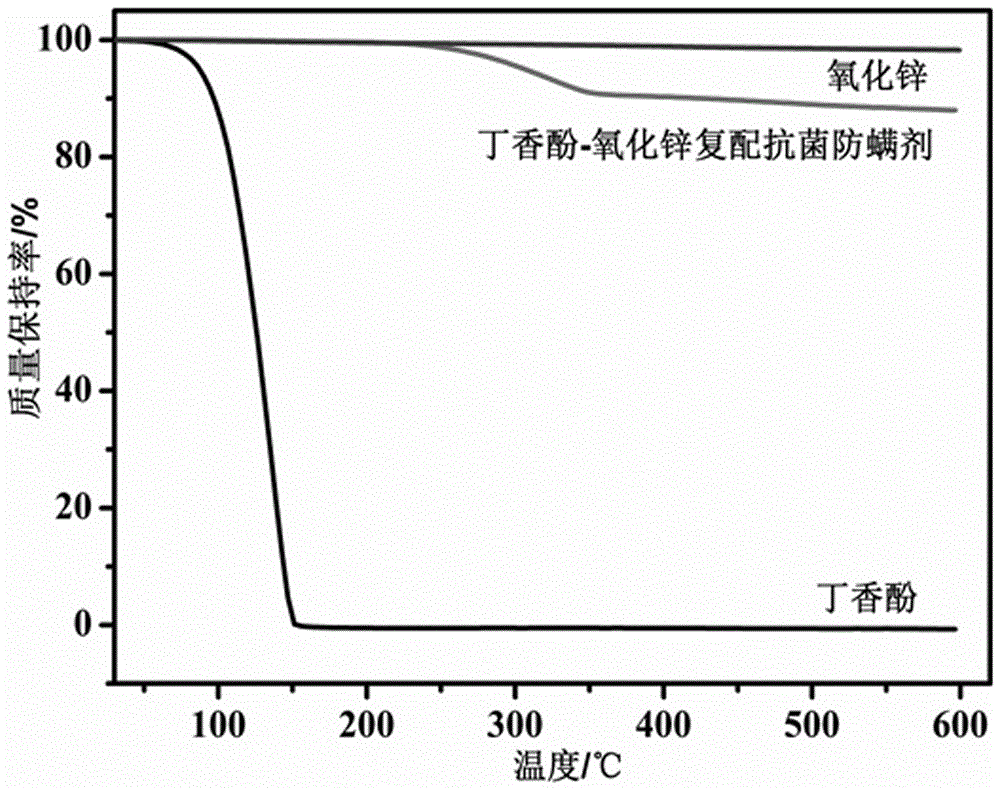

An anti-mite and fiber technology, applied in the field of fiber and fabric manufacturing, can solve the problems of poor heat resistance, few fibers, and no effective ingredients are published, and achieve the effects of strong sterilization and improved antibacterial and anti-mite effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 Preparation of a kind of antibacterial and anti-mite polypropylene fiber

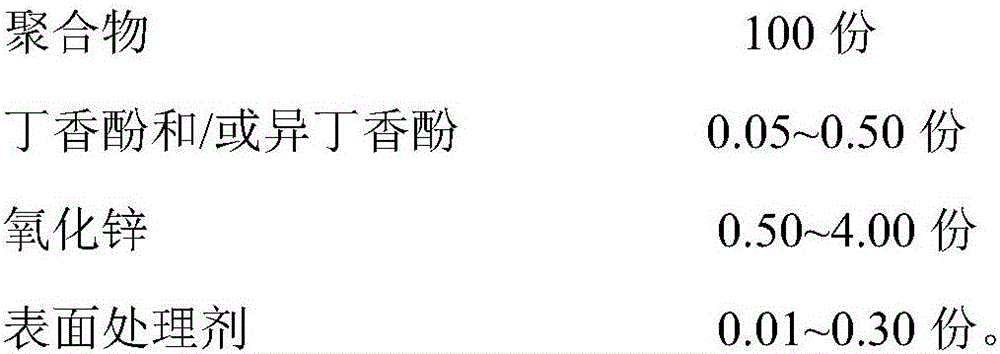

[0043] (1) The formula for preparing antibacterial and anti-mite polypropylene fibers is as follows (parts by weight):

[0044]

[0045] (2) The preparation of antibacterial and anti-mite polypropylene fiber comprises the following steps:

[0046]Step 1: Take by weighing 0.05 part (weight) of organic anti-mite agent isoeugenol and 1.00 part (weight) of inorganic antibacterial agent zinc oxide, add to high-speed mixer and stir at high speed, after mixing evenly, grind and refine through planetary ball mill, pass Sieve to obtain an isoeugenol / zinc oxide compound antibacterial and anti-mite powder with an average particle size of 1.18 μm;

[0047] Step 2: Place the refined isoeugenol / zinc oxide compound antibacterial and anti-mite powder in a high-speed mixer, and add 0.09 parts (weight) of silane coupling agent KH-570 to surface it during stirring and mixing. Coating and modificat...

Embodiment 2

[0049] Embodiment 2 Preparation of a kind of antibacterial and anti-mite nylon 6 fiber

[0050] (1) The formula for preparing antibacterial and anti-mite nylon 6 fibers is as follows (parts by weight):

[0051]

[0052] (2) The preparation of antibacterial and anti-mite nylon 6 fiber comprises the following steps:

[0053] Step 1: Take by weighing 0.25 parts (weight) of the organic anti-mite agent eugenol and 0.25 parts (weight) of isoeugenol and 2.50 parts (weight) of the inorganic antibacterial agent zinc oxide, add to a high-speed mixer and stir at a high speed. The planetary ball mill grinds and refines, and sieves to obtain (eugenol + isoeugenol) / zinc oxide compound antibacterial and anti-mite powder with an average particle size of 1.12 μm;

[0054] Step 2: Place the refined (eugenol+isoeugenol) / zinc oxide compound antibacterial and anti-mite powder in a high-speed mixer, and add 0.10 parts (weight) of silane coupling agent KH- 550 and 0.05 parts (weight) of titaniu...

Embodiment 3

[0057] Embodiment 3 Preparation of a kind of antibacterial and anti-mite polyethylene fiber

[0058] (1) The formula for preparing antibacterial and anti-mite polyethylene fibers is as follows (parts by weight):

[0059]

[0060] (2) the preparation of antibacterial anti-mite polyethylene fiber comprises the following steps:

[0061] Step 1: Weigh 0.25 parts (weight) of the organic anti-mite agent eugenol and 4.00 parts (weight) of the inorganic antibacterial agent zinc oxide, add them to a high-speed mixer for high-speed stirring, mix evenly, grind and refine them by a planetary ball mill, and sieve , the compound antibacterial and anti-mite powder of eugenol / zinc oxide with an average particle size of 1.05 μm was prepared;

[0062] Step 2: Place the compound antibacterial and anti-mite powder of the refined eugenol / zinc oxide in a high-speed mixer, add 0.30 parts (weight) of titanate coupling agent to coat it on the surface during stirring and mixing Coated modified tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com