High-current carrying capacity cable for marine engineering drilling rigs

A technology for marine engineering and drilling towers, which is applied in the direction of insulated cables, flexible cables, and power cables with shielding layers/conductive layers, etc. It can solve problems such as increased cable temperature rise, reduced comprehensive oxygen index, and cable burnout. Achieve the effects of good bending performance, high light transmittance, and small burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

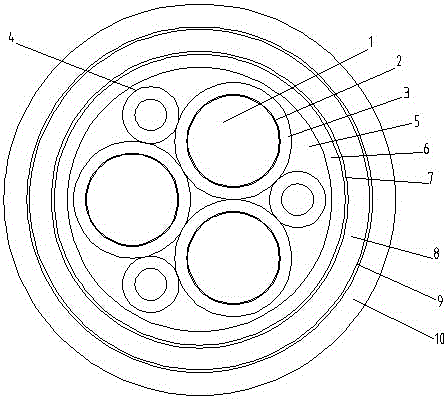

[0015] A high-capacity cable for marine engineering drilling towers, the cable includes three insulated cores and three grounding cores, the three insulated cores and the three grounding cores are twisted together to form a cable core, and the insulated The wire core is composed of a conductor 1 and an insulating layer 2 and an isolation layer 3 provided outside the conductor 1. The grounding wire core 4 is composed of a grounding wire conductor and an insulating layer 2 covered by the grounding wire conductor. The surface is successively provided with a thermal insulation buffer layer 5, a metal wire shielding layer 6, and a metal tape shielding layer 7, and the outermost layer is provided with a reinforced outer sheath.

[0016] The reinforced outer sheath is composed of a reinforced outer sheath inner layer 8, a reinforced outer sheath outer layer 10 and an aramid fiber net 9 between them.

[0017] The conductor 1 adopts the fifth type of twisted circular conductor specifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com