A kind of carbon/silicon carbide composite material non-destructive testing standard sample preparation method

A composite material and non-destructive testing technology, which is applied in the preparation of test samples, etc., can solve the problems of easy carbonization of carbon slag and inapplicability of porcelain-based composite materials, and achieve the effects of good stability, material reduction, and easy realization

Active Publication Date: 2010-08-04

NORTHWESTERN POLYTECHNICAL UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that the plastic film is easy to carbonize and leave carbon residue after pyrolysis.

Porcelain matrix composites are obviously not suitable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

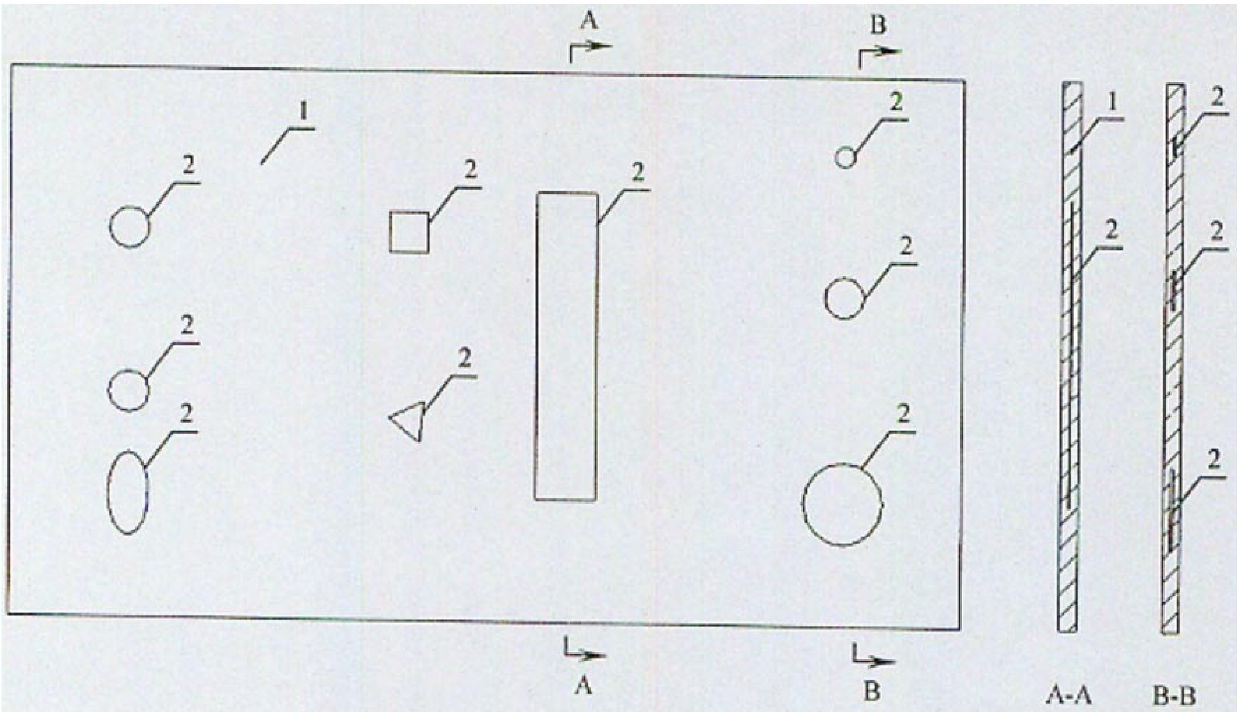

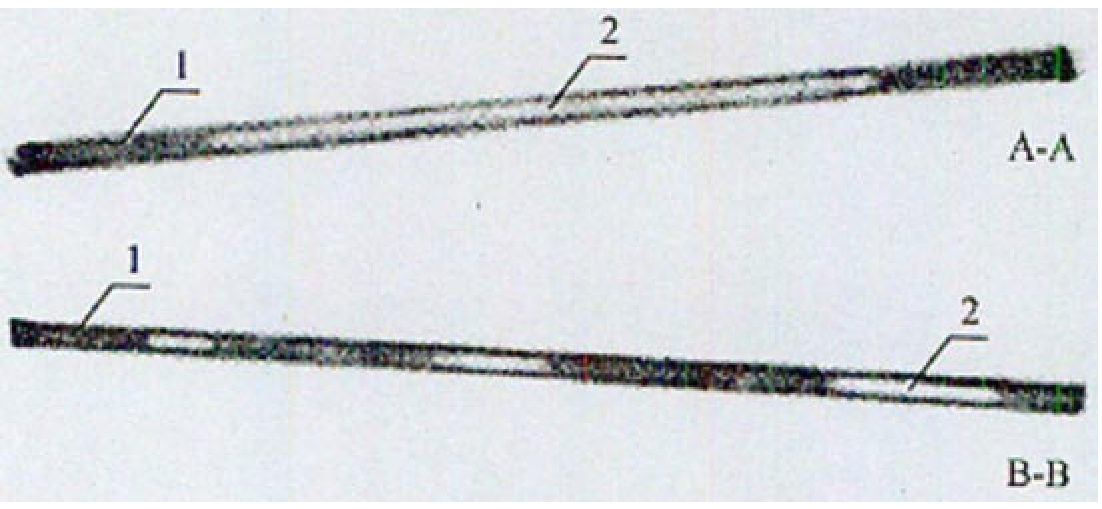

The invention relates to a method for preparing a carbon / silicon carbide composite material non-destructive testing standard sample. Said preparation method includes preparing C fiber prefabricated body, making artificial defects of graphite paper, placing artificial defects, chemical vapor deposition (CVI) impregnating pyrolytic C, CVI impregnating SiC matrix and the like. The preparation method of the invention is simple, can prepare a non-destructive testing standard sample that is as dense as a non-defective material, has good material integrity, almost no volume change in the preparation process, and has good shape stability of the prepared material and defects. The C / SiC ceramic matrix composite material non-destructive testing standard sample prepared by the method of the invention is mainly used for type identification, damage degree judgment and non-destructive testing equipment calibration of the material defects in the fields of aviation, aerospace and weapons.

Description

A kind of carbon / silicon carbide composite non-destructive testing standard sample preparation method technical field The present invention relates to a kind of carbon / silicon carbide composite material non-destructive testing standard sample preparation method, particularly relate to a kind of continuous Preparation method of non-destructive testing standard samples for carbon fiber reinforced silicon carbide laminates. Background technique The manufacturing cost of advanced ceramic matrix composite (CMC) is usually very high, and the production cycle is long, and the use environment has a great influence on its quality. How to effectively improve its reliability is a very urgent problem. Use appropriate non-destructive evaluation methods for possible Effective detection of existing defects, guarantee of finished product quality and service life performance, and improvement of product reliability will play a very important role key role. [0003] C / SiC composite ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/28

Inventor 徐永东成来飞张立同梅辉赵东林王东涂建勇陈旭付志强

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com