Eleutherine americana oxidation-resistant beverage and preparation method thereof

An anti-oxidation and red onion technology is applied in the direction of food ingredients containing natural extracts, food ingredients as odor improvers, and the functions of food ingredients. Promoting the effect of app value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

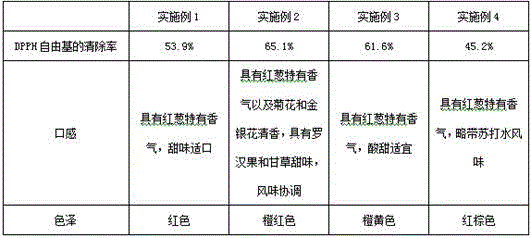

Examples

Embodiment 1

[0036] The raw material of fresh red onion is dried with hot air at 50°C for 24 hours, crushed through a 40-mesh sieve, and water is added as a solvent at a material-to-liquid ratio of 1:150. Cellulase (10000U / g) is added in an amount of 1%, and ultrasonically assisted extraction 2 times, each extraction time is 40min, and the red onion water extract is obtained by vacuum filtration.

[0037] The preparation is carried out according to the following proportions: 70 parts of shallot aqueous extract, 5 parts of xylitol, 0.005 part of stevioside, 0.05 part of CMC-Na, 0.2 part of β-cyclodextrin, and 25 parts of water.

[0038] Raise the temperature of the prepared mixture to 50°C, and homogenize with a high-pressure homogenizer at a pressure of 15 MPa, and homogenize once. Fill the homogeneous mixed solution into a glass bottle with a screw cap and seal it, sterilize it at 121°C for 20 minutes, and obtain the finished product after cooling.

Embodiment 2

[0040] The raw material of fresh shallots was dried with hot air at 50°C for 24 hours, crushed and passed through a 40-mesh sieve, water was added as a solvent at a material-to-liquid ratio of 1:100, cellulase (15000U / g) was added in an amount of 1%, and ultrasonic-assisted extraction was used to obtain The extraction solution was used for ultrasonic-assisted extraction for 2 times, each extraction time was 30 minutes, and the red onion water extract was obtained by vacuum filtration.

[0041] Luo Han Guo, licorice, chrysanthemum, and honeysuckle were added to 100 times of water at a mass ratio of 1:1:1:1, ultrasonically assisted extraction at 80°C for 30 minutes, and vacuum filtration to obtain herbal water extracts.

[0042] Prepare according to the following proportions: 60 parts of red onion water extract, 20 parts of herbal plant water extract, 4 parts of maltitol, 0.005 part of stevioside, 0.05 part of CMC-Na, 0.2 part of β-cyclodextrin, 16 parts of water share.

[0043...

Embodiment 3

[0045] The raw material of fresh red onion was dried with hot air at 50°C for 24 hours, crushed through a 40-mesh sieve, added water as a solvent according to the ratio of solid to liquid 1:125, added 1% of cellulase (20000U / g), and extracted 2 with the aid of ultrasound times, each extraction time is 40min, and the red onion water extract is obtained by vacuum filtration.

[0046] It is formulated according to the following proportions: 80 parts of red onion water extract, 5 parts of erythritol, 0.002 part of sucralose, 0.03 part of xanthan gum, 0.15 part of citric acid, 0.2 part of β-cyclodextrin, and 15 parts of water.

[0047] Raise the temperature of the prepared mixed solution to 60°C, and homogenize with a high-pressure homogenizer at a homogenization pressure of 20 MPa, and homogenize twice. The homogeneous mixture is filled in a glass bottle and sealed with a screw cap, sterilized at 100°C for 15 minutes, and the finished product is obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com